Forming method for improving structure uniformity of titanium alloy bar by combining free forging and pulse current auxiliary extrusion

A technology of pulse current and uniform structure, applied in the direction of metal processing equipment, etc., can solve the problems of aerospace, poor micro-uniformity, and reduced mechanical properties, etc., to compensate for uneven distribution of temperature field, large temperature window, and mechanical performance indicators Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Ti6554 rod preparation

[0042] The chemical composition of Ti6554 titanium alloy is (%, mass fraction): chromium 5.7, molybdenum 4.7, vanadium 4.8, aluminum 3.9, iron 0.08, silicon 0.028, carbon 0.025, and the rest of titanium. Phase transition temperature T of Ti6554 β =820°C, which belongs to high-strength and tough near-β titanium alloy with high content of alloying elements, so a 70kg ingot (diameter 170mm×length 200mm) was obtained by smelting three times in a vacuum consumable electric arc furnace. The specific smelting parameters are shown in Table 1.

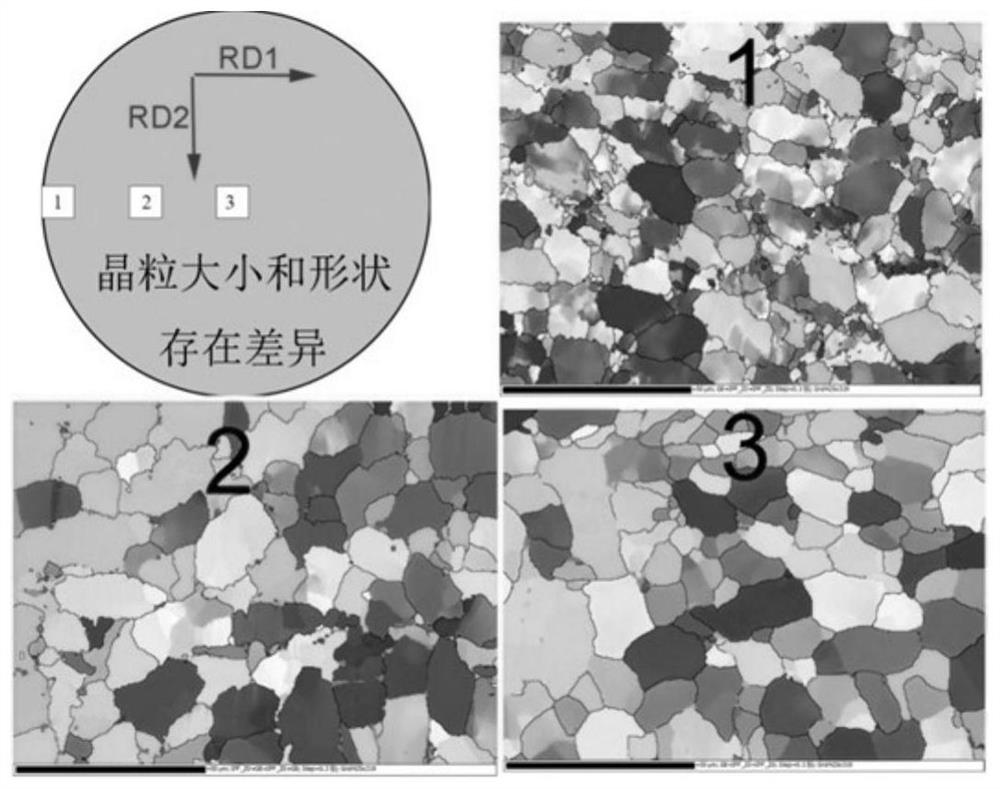

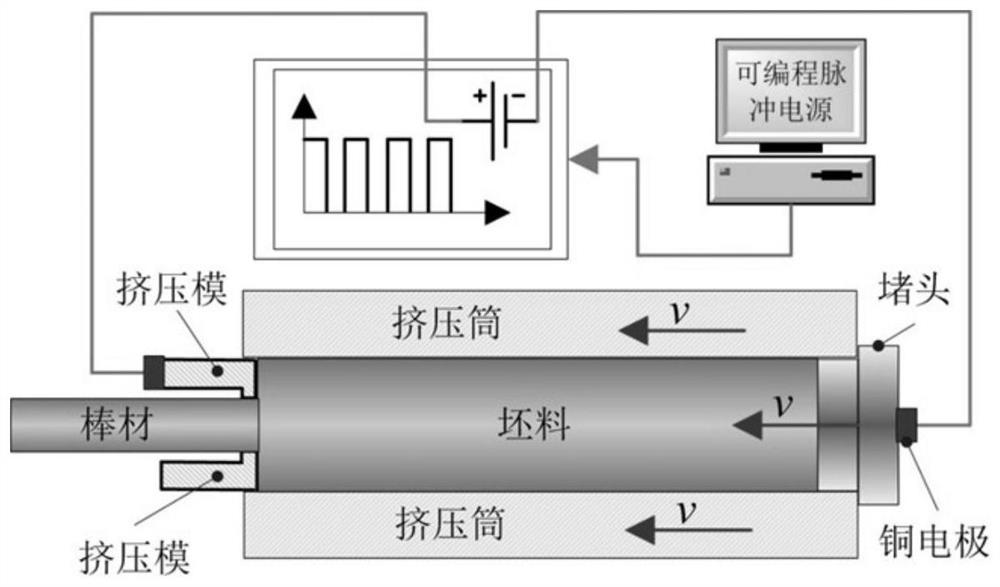

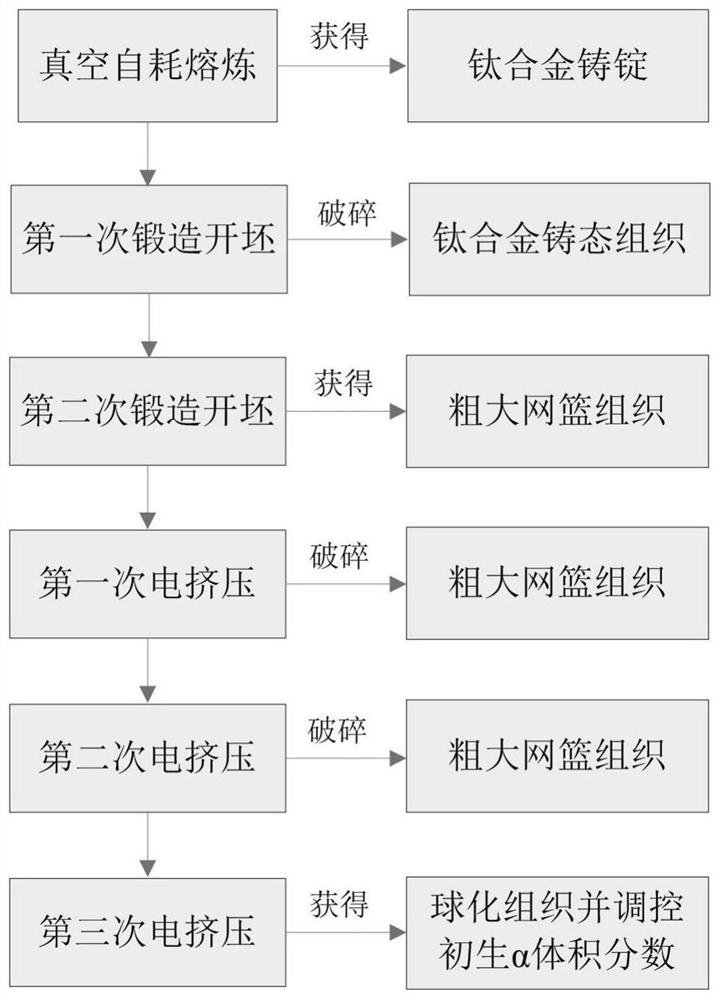

[0043] Heat the 70kg ingot to 1150°C for 2 hours, quickly move it to a 3-ton hammer forging machine, implement A and B upsetting and drawing deformation treatments to complete the free forging billet opening process, and obtain a forged bar with a diameter of 100mm. Perform A and B extrusion deformation treatments to complete the pulse current assisted extrusion process of forged bars (see Table 2 ...

Embodiment 2

[0044] Embodiment 2: Ti55531 rod preparation

[0045] The chemical composition of the Ti55531 titanium alloy is (%, mass fraction): aluminum 5.3, molybdenum 5.2, vanadium 5.2, chromium 2.65, zirconium 1.02, and the rest of titanium. Phase transition temperature T of Ti55531 β =850°C, which belongs to high-strength and tough near-β titanium alloy with high content of alloying elements, so a 70kg ingot (diameter 170mm×length 200mm) was obtained by smelting three times in a vacuum consumable electric arc furnace. The melting parameters are shown in Table 1.

[0046] Heat the 70kg ingot to 1100°C for 2 hours, quickly move it to a 3-ton hammer forging machine, perform A and B upsetting and drawing to complete the free forging billet opening process, and obtain a forged bar with a diameter of 100mm. Extrusion A and B were performed to complete the pulse current assisted extrusion process for the forged bar (see Table 3 for specific process parameters), and a bar with a diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com