Device for polishing outer end face of ceramic mixed-voltage integrated circuit board and method

A technology for integrated circuit boards and outer end surfaces, which is applied in the direction of grinding drive devices, grinding machines, grinding workpiece supports, etc., can solve the problems of reducing grinding efficiency, increasing grinding time, and limited number of pieces to be polished, and achieves improved grinding efficiency and structure Compactness and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

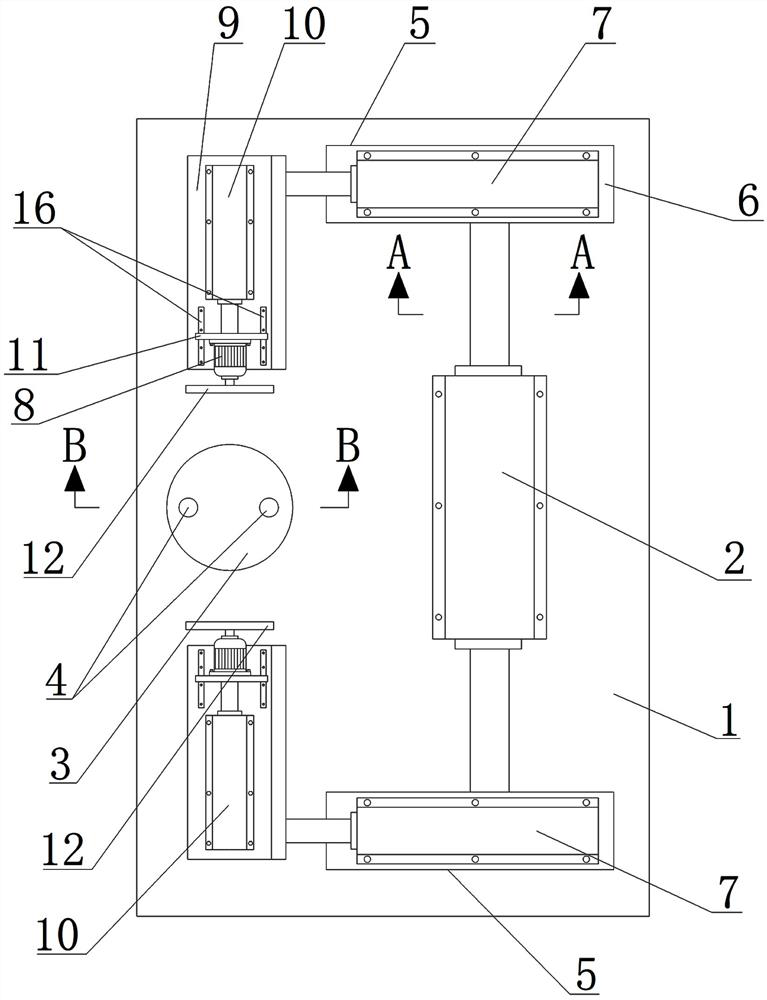

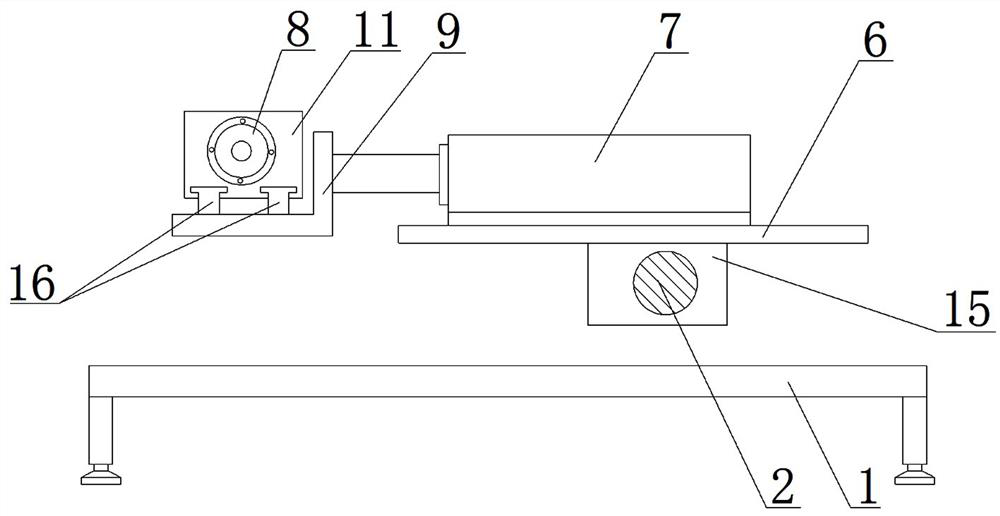

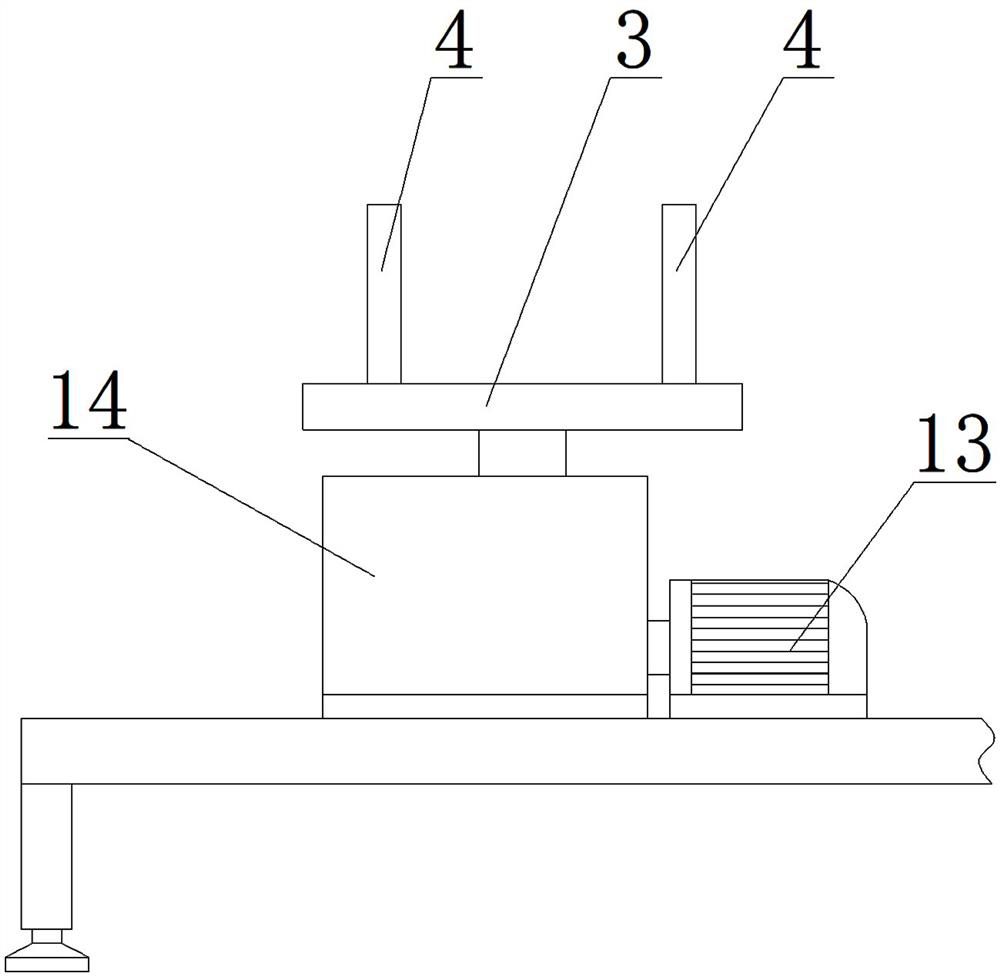

[0028] Such as Figure 1~3 As shown, a grinding device for the outer end surface of a ceramic mixed-pressure integrated circuit board includes a workbench 1, a power unit arranged on the workbench 1, and a double-acting oil cylinder 2. A turntable 3 is installed on the output shaft of the power unit, and the turntable The top surface of 3 is fixedly provided with two limit rods 4, and the action ends of the two piston rods of the double-acting oil cylinder 2 are all provided with a grinding mechanism 5, and the two grinding mechanisms 5 are symmetrically arranged front and rear about the turntable 3, and the grinding mechanism 5 includes Mounting plate 6, feed oil cylinder 7 and motor 8, mounting plate 6 is fixed on the action end of double-acting oil cylinder 2 piston rod, feed oil cylinder 7 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com