Device and method for manufacturing sidewall hot-laminating covering rubber and control system

A manufacturing device and thermal lamination technology, which is applied in the field of sidewall thermal lamination cover rubber manufacturing equipment, can solve the problems that the white glue cannot accurately display the sidewall markings, the tire rigidity is unbalanced, and the overall performance of the tire is affected. Avoid the impact of inconsistent tire thickness on driving safety, improve plasticity and ductility, and reduce the waste of colored rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

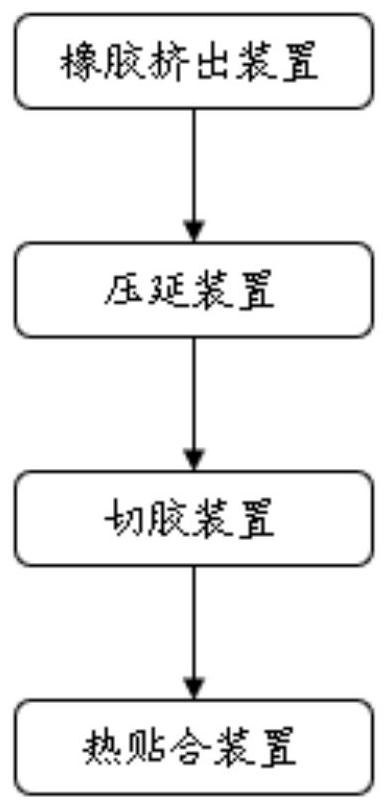

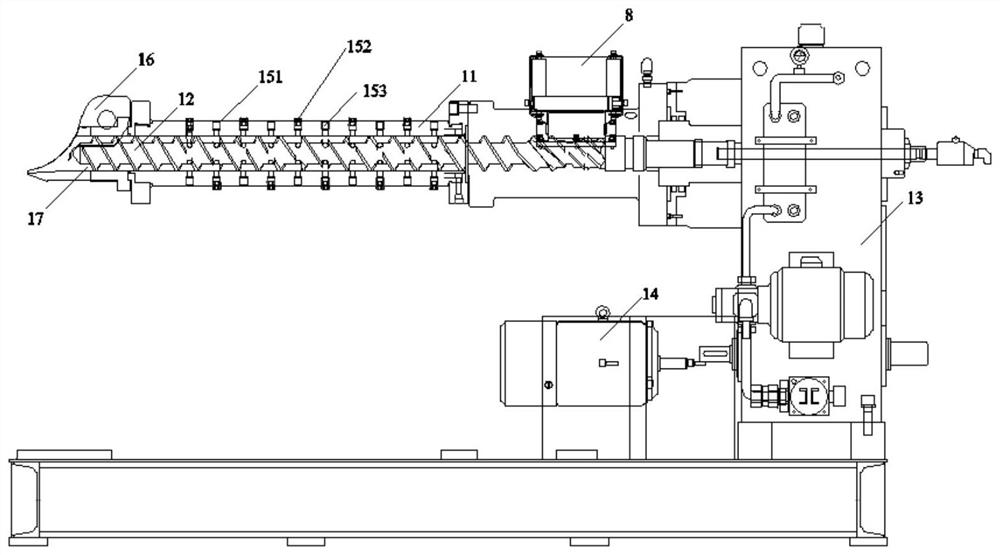

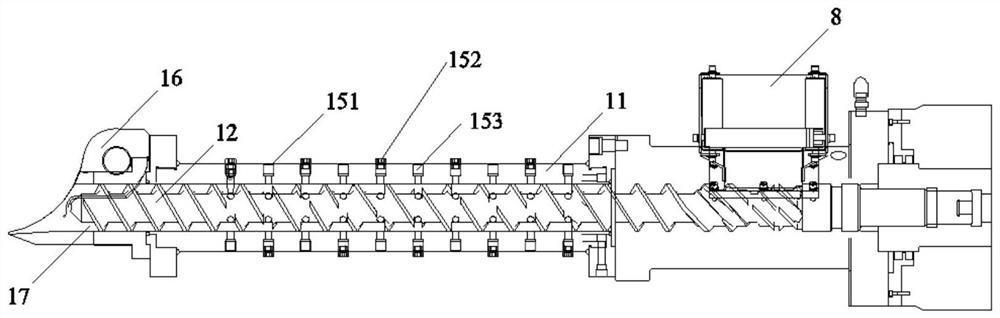

[0058] Hereinafter, the detailed structure of each part of the sidewall heat bonding cover rubber manufacturing device will be described through the first embodiment.

[0059] The extrusion device 1 includes a barrel 11, a single-screw structure 12, a first reduction box 13 and a head 17, such as Figure 2-4 As shown, the rubber raw material enters from the rubber raw material inlet 8, and is extruded through the barrel 11 and the single screw 12. The upper structure of the single screw 12 has a saw-toothed helix. The head of the single screw structure 12 is connected with the first reduction box by splines. The first reduction box 13 has a first circular shaft, a second circular shaft, and a third circular shaft. Fourth circular axis. The first gear is arranged on the first circular shaft, the second gear and the third gear are arranged on the second circular shaft, the fourth gear and the fifth gear are arranged on the third circular shaft, and the sixth gear is arranged on...

Embodiment 2

[0074] Further, in order to avoid the problem of uneven thickness during the manufacturing process of the covering glue, in view of this, a temperature control system, an alarm system, a temperature control method, and an alarm method are provided. Specifically, the first pressure and / or the first temperature are determined based on the temperature and composition of the rubber raw material.

[0075] The sidewall heat lamination cover rubber manufacturing device is equipped with a control system, and the control system includes a controller, an interactive device, a readable storage medium, a bus and a display.

[0076] The temperature control system includes a first temperature control system and a second temperature control system, the first temperature control system is used to control the temperature of the extrusion device, and the second temperature control system is used to control the temperature of the calendering device , The temperature control system includes a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com