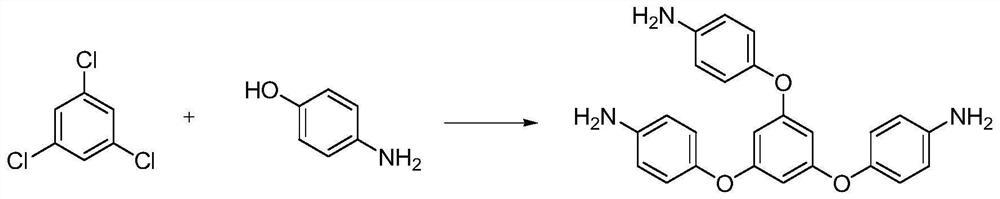

Method for preparing 1, 3, 5-tri (4-aminophenoxy) benzene

A technology of aminophenoxy and trichlorobenzene, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxyl compounds, etc., can solve the problems of inapplicability to mass production, low production efficiency, and low yield of products, etc. problems, to achieve the effect of high product yield, lower production cost, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 32.7g of 4-hydroxyaniline to the reaction flask, add it to 350g of sulfolane, add 15g of cesium hydroxide in batches under mechanical stirring, then raise the temperature to 60°C, slowly add 18g of trichlorobenzene, 1.5g of cesium fluoride, and then Raise the temperature to 130°C and keep the reaction at this temperature. After the raw materials have reacted completely, the reaction solution is cooled to 60°C and filtered with diatomaceous earth. The filter cake is washed with sulfolane, and half of the solvent is recovered from the filtrate under reduced pressure. , add water to the reaction solution, cool down to below 10°C in an ice bath under stirring, filter, wash with water, and dry in a vacuum oven to obtain 1,3,5-tris(4-aminophenoxy)benzene, 32.7g, off-white solid , yield 81.95%.

Embodiment 2

[0030] Add 32.8g of 4-hydroxyaniline to the reaction flask, add it to 500g of sulfolane, add 18g of cesium hydroxide in batches under mechanical stirring, then raise the temperature to 60°C, slowly add 18g of trichlorobenzene, 4.5g of cesium fluoride, and then Raise the temperature to 160°C and keep the reaction at this temperature. After the reaction of the raw materials is complete, the reaction solution is cooled to 60°C and filtered with diatomaceous earth, the filter cake is washed with sulfolane, half of the solvent is recovered from the filtrate under reduced pressure, water is added to the reaction solution, and stirred Lower the temperature in an ice bath to below 10°C, filter, wash with water, and dry in a vacuum oven to obtain 1,3,5-tris(4-aminophenoxy)benzene, 37.4 g, off-white solid, with a yield of 93.73%.

Embodiment 3

[0032] Add 32.9g of 4-hydroxyaniline to the reaction flask, add it to 750g of sulfolane, add 19.5g of cesium hydroxide in batches under mechanical stirring, then raise the temperature to 60°C, slowly add 18g of trichlorobenzene, 7.6g of cesium fluoride, After that, the temperature was raised to 160°C, and the reaction was maintained at this temperature. After the raw materials were completely reacted, the reaction solution was cooled to 60°C and filtered with diatomaceous earth. The filter cake was washed with sulfolane, and half of the solvent was recovered from the filtrate under reduced pressure, and water was added to the reaction solution. Cool down to below 10°C in an ice bath with stirring, filter, wash with water, and dry in a vacuum oven to obtain 1,3,5-tris(4-aminophenoxy)benzene, 37.5 g, off-white solid, yield 93.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com