A low-temperature activated vanadium-based hydrogen storage alloy and its preparation method and application

A low-temperature activation and hydrogen storage alloy technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of troublesome processing and increased raw material costs, reduce the activation temperature, facilitate large-scale promotion and use, and have broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a low-temperature activated vanadium-based hydrogen storage alloy, and the element composition of the low-temperature activated vanadium-based hydrogen storage alloy is Ti 0.05 Cr 0.15 V 0.8 Ce 0.02 ;

[0081] Prepared by the following preparation method:

[0082] (1) batching: according to the atomic ratio, weigh elemental metal with a purity of ≥99.9 wt.% and perform batching to obtain a mixture;

[0083] (2) smelting: the mixture described in step (1) is loaded into the water-cooled copper mold of the non-consumable vacuum arc furnace, then placed in the vacuum arc furnace and smelted under the protection of argon, the current in the smelting It is 200A, and the single melting time is 150s. After the single melting, let the alloy cool down to room temperature with the copper crucible, turn it over, and then carry out a new melting, and repeat the melting for 4 times to obtain the alloy ingot;

[0084] Wherein, the alloy ingot includes a ...

Embodiment 2

[0089] This embodiment provides a low-temperature activated vanadium-based hydrogen storage alloy, and the element composition of the low-temperature activated vanadium-based hydrogen storage alloy is Ti 0.05 Cr 0.15 V 0.8 Ce 0.01 That is, "x=0.02" in Example 1 is changed to "x=0.01", and other conditions are exactly the same as Example 1.

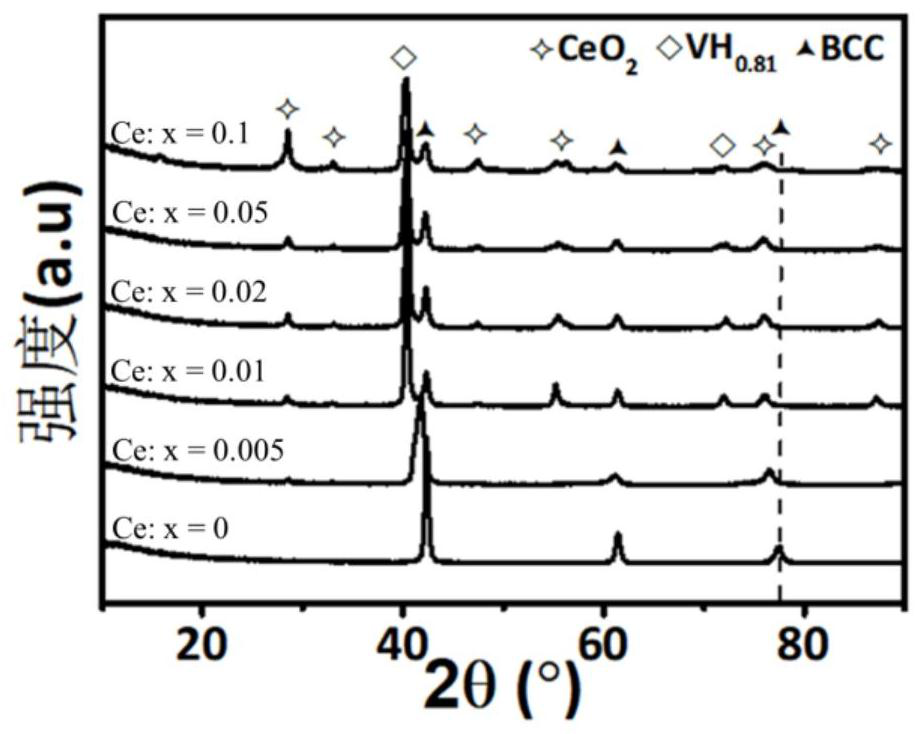

[0090] The XRD spectrum of the low-temperature activated vanadium-based hydrogen storage alloy described in this embodiment is as follows figure 1 As shown, the alloy includes the BCC phase and contains CeO 2 Components and VH 0.81 ;

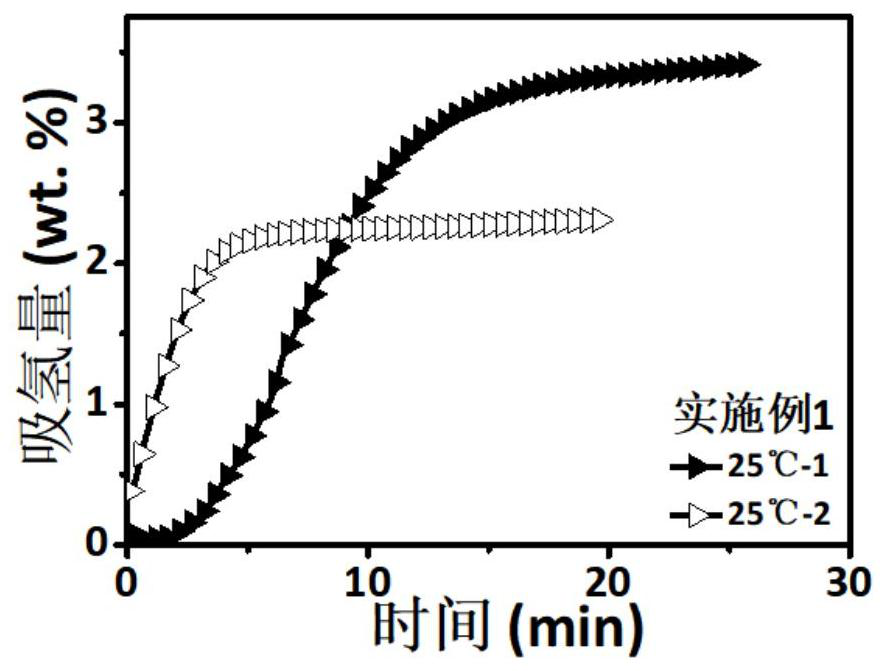

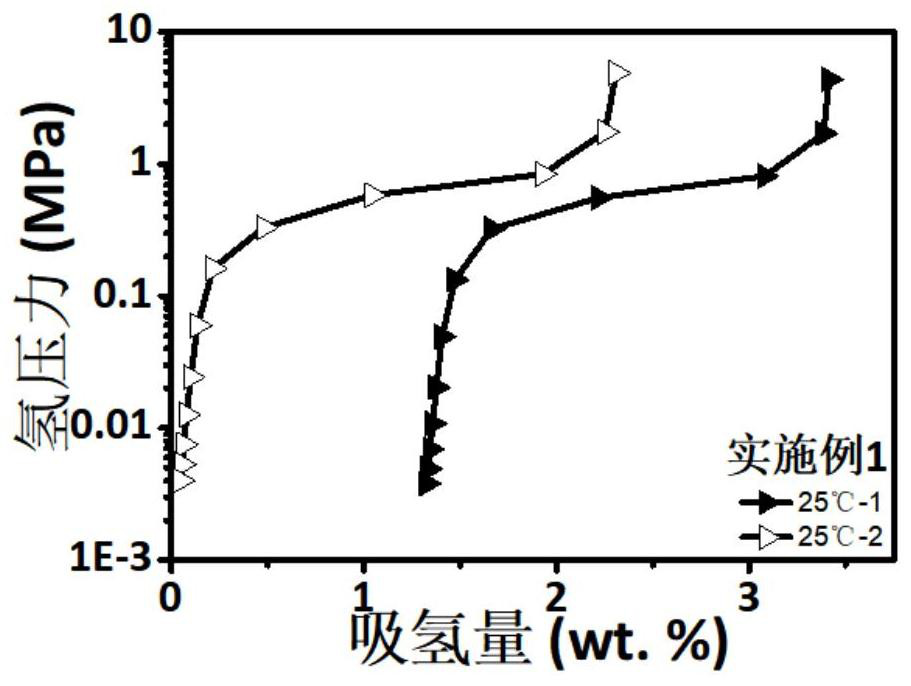

[0091] Put the low-temperature activated vanadium-based hydrogen storage alloy described in this example into the stainless steel reaction vessel, and use the PCT hydrogen absorption and desorption test equipment to carry out the hydrogen absorption and desorption performance test: in the case of no activation, at 8MPa H 2 and the first hydrogen absorption at room temperature of 25 °C, at 0.1 MPa H 2 ...

Embodiment 3

[0093] This embodiment provides a low-temperature activated vanadium-based hydrogen storage alloy, and the element composition of the low-temperature activated vanadium-based hydrogen storage alloy is Ti 0.05 Cr 0.15 V 0.8 Ce 0.05 That is, "x=0.02" in Example 1 is changed to "x=0.05", and other conditions are exactly the same as Example 1.

[0094] The XRD spectrum of the low-temperature activated vanadium-based hydrogen storage alloy described in this embodiment is as follows figure 1 As shown, the alloy includes the BCC phase and contains CeO 2 Components and VH 0.81 ;

[0095] Put the low-temperature activated vanadium-based hydrogen storage alloy described in this example into the stainless steel reaction vessel, and use the PCT hydrogen absorption and desorption test equipment to carry out the hydrogen absorption and desorption performance test: in the case of no activation, at 8MPa H 2 and the first hydrogen absorption at room temperature of 25 °C, at 0.1 MPa H 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com