A kind of room temperature hydrogen-absorbing carbon airgel material and preparation method thereof

A carbon aerogel, room temperature technology, applied in the field of hydrogen absorption, can solve problems such as explosion and corrosion of active metal materials, and achieve the effects of convenient use, reduced corrosion, and adjustable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

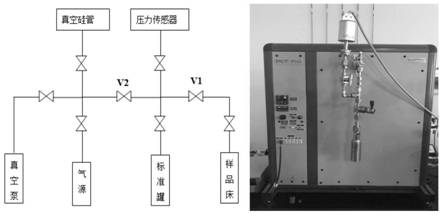

Method used

Image

Examples

Embodiment 1

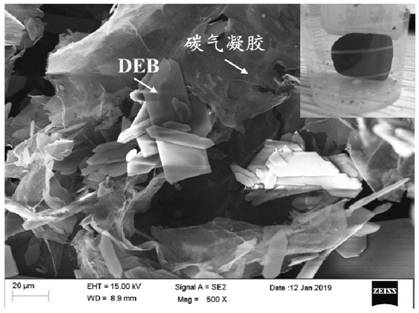

[0041] The preparation of embodiment 1 carbon airgel

[0042] Weigh 0.2 grams of graphene oxide (JCGO-98-1-50) and 0.1 grams of carbon nanotubes (JCMT-70-35-5) respectively, place them in 100 ml of deionized water, and ultrasonically disperse them for 60 minutes to form graphene oxide - carbon nanotube mixed solution (mixed solution 1); then add dropwise 10 milliliters, 0.04 mol / liter of sodium bisulfite solution to the above mixed solution, continue ultrasonication for 30 minutes and reduce at 90 degrees Celsius for 5 hours at high temperature , to obtain a reduced graphene oxide-carbon nanotube mixed solution (mixed solution 2); the mixed solution 2 is poured into a container of a specified shape, put into a freeze dryer and frozen at -5 degrees Celsius for 72 hours to remove moisture, that is carbon aerogels.

Embodiment 2

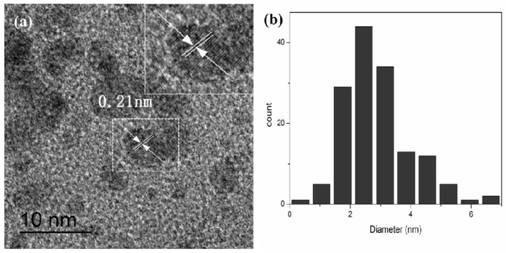

[0043] The preparation of the carbon aerogel of embodiment 2 load nano palladium catalysts

[0044] Put 0.075 grams of carbon airgel in 10 milliliters of deionized water, then add 10 milliliters of 0.04 mmol / L sodium tetrachloropalladate solution dropwise under the action of ultrasound, and continue to sonicate for 5 minutes after the addition; then add dropwise 5 ml, 0.05 mmol / L (excessive) sodium borohydride solution, after the dropwise addition, sonicate for 5 minutes. Take out the carbon aerogel loaded with nano-palladium catalyst and put it into a lyophilizer and freeze it at -5 for 72 hours to remove moisture, and then obtain the dry carbon aerogel loaded with nano-palladium catalyst.

Embodiment 3

[0045] The preparation of the carbon aerogel of embodiment 3 loaded nano palladium / nickel catalysts

[0046] 0.075 g of carbon airgel was placed in 10 ml of deionized water, and then 10 ml of a mixed solution of 0.03 mmol / L sodium tetrachloropalladate and 0.02 mmol / L nickel nitrate monohydrate was added dropwise under ultrasonication, After the dropwise addition, continue to sonicate for 5 minutes; then add 5 ml of 0.05 mmol / L (excessive) sodium borohydride solution dropwise, and then sonicate for 5 minutes after the dropwise addition. Take out the carbon aerogel loaded with nano-palladium / nickel catalyst and put it into a lyophilizer and freeze it at -5 for 72 hours to remove moisture to obtain a dry carbon aerogel loaded with nano-palladium / nickel catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com