Electrolyte additive, electrolyte, and secondary battery

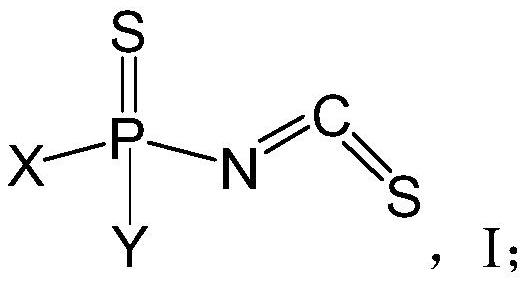

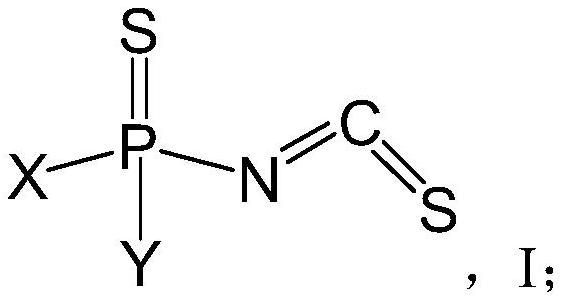

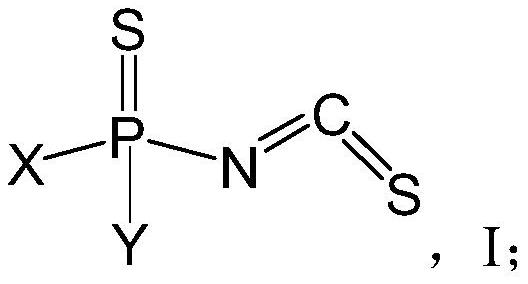

An electrolyte additive and electrolyte technology, which are applied in the fields of secondary batteries, electrolytes, and electrolyte additives, can solve the problems of poor safety performance of positive and negative electrode materials with high gram capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] an electrolyte , and its preparation includes the steps of: mixing 300g of EC, 600g of EMC, and 100g of DEC in a glove box with a water content of less than 1ppm and an oxygen content of less than 2ppm to form a mixed organic solvent; then, adding an appropriate amount of fully dried LiPF 6 The lithium salt concentration of the electrolyte is 1 mol / L to obtain a basic electrolyte. Then add 0.05% SPNCS-1 to the basic electrolyte, Electrolyte E1 is obtained.

[0059] A lithium ion battery , its production includes the steps:

[0060] ① Mix the positive electrode material Ni83, carbon black, carbon nanotubes, and polyvinylidene fluoride PVDF in a ratio of 100:0.6:0.6:1.5, coat it on a 12μm aluminum foil, and then dry it at 85°C to obtain the positive electrode piece.

[0061] ② Mix graphite material, carbon black, styrene-butadiene rubber SBR, and sodium carboxymethyl cellulose CMC in a ratio of 100:0.9:1.9:1.5, coat it on an 8μm copper foil, and then dry it at 90°C ...

Embodiment 2

[0065] an electrolyte , the difference from Example 1 is: add 0.1% SPNCS-2 in the electrolyte, Electrolyte E2 is obtained.

[0066] A lithium ion battery , which differs from Example 1 in that: the electrolyte E2 is used, and the obtained lithium ion battery is C2.

Embodiment 3

[0068] an electrolyte , its difference from Example 1 is: add 0.5% SPNCS-3 in the electrolyte, Electrolyte E3 is obtained.

[0069] A lithium ion battery , which differs from Example 1 in that: the electrolyte E3 is used, and the obtained lithium ion battery is C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com