Cobalt tungstate/bismuth/bismuth oxybromide ternary heterojunction composite material and preparation method and application thereof

A technology of bismuth oxybromide ternary and composite materials, which is applied in the field of composite acoustic catalyst preparation, can solve the problems of not meeting actual needs and low separation efficiency, achieve good application prospects, simple preparation process, and improve the effect of acoustic catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

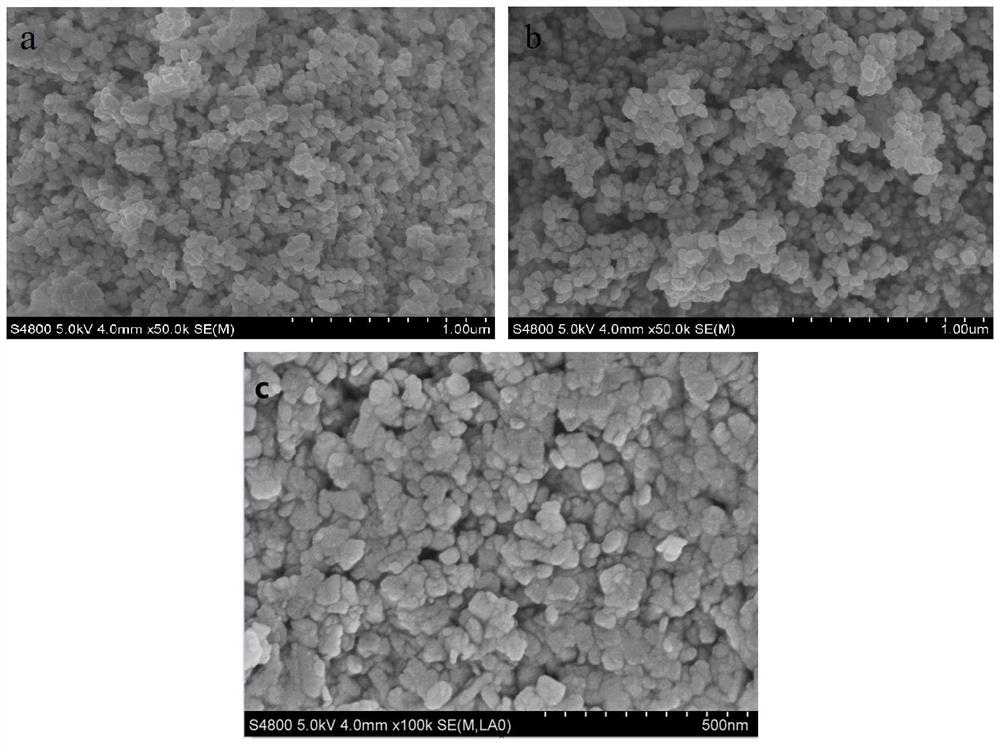

[0024] The preparation of embodiment 1 cobalt tungstate

[0025] 1.4551g Co(NO 3 ) 2 ·6H 2 O and 1.6493g Na 2 WO 4 2H 2 O was dissolved in a 100mL Erlenmeyer flask with 30mL of deionized water respectively; the two were mixed, and the mixture was magnetically stirred for 30min; after ultrasonic reaction for 30min, it was poured into a polytetrafluoroethylene reactor, and placed in a blast drying oven for 180 ℃ for 24 hours; after the reaction, filter with suction, dry at 80℃ for 2 hours, grind into a fine powder with an agate mortar, and obtain CoWO 4 powder.

Embodiment 2

[0026] The preparation of embodiment 2 cobalt tungstate / bismuth composite material

[0027] 10.5993g NaPO 2 h 2 .H 2 O was dissolved in 50ml deionized water, and after magnetic stirring for 20min, 0.45027gC was added 4 h 4 o 6 and 0.08g NaOH NaOH, after continuing magnetic stirring for 30min, add 1.5g CoWO 4 Ultrasonic treatment, to obtain A solution to obtain a solution. 1.2127Bi(NO 3 ) 3 ·5H 2 O dissolved in 5ml HNO 3 , solution B was obtained after magnetic stirring. Under the condition of magnetic stirring, add solution B to solution A drop by drop, put it in an oven at 60°C for 6 hours for hydrothermal reaction, filter with suction, wash with deionized water to obtain the sample, and put the sample at 70-90 ℃ drying for 2 hours to obtain cobalt tungstate / bismuth nanoparticles.

Embodiment 3

[0028] Example 3 Preparation of cobalt tungstate / bismuth / bismuth oxybromide ternary heterojunction composite material

[0029] Evenly disperse 0.16245g of potassium bromide into 20ml of ethylene glycol, evenly disperse 0.16245g of bismuth nitrate into 100ml of deionized water to prepare a bismuth nitrate solution, add 0.2g of cobalt tungstate / bismuth nanoparticles into the bismuth nitrate solution, Then the above two solutions were mixed, magnetically stirred for 30 min, and ultrasonicated for 30 min. Suction filter and dry at 70-90°C for 2h. Cobalt tungstate / bismuth / bismuth oxybromide powder (1:2) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com