Method and system for recovering nitric acid and copper sulfate from deplating waste liquid

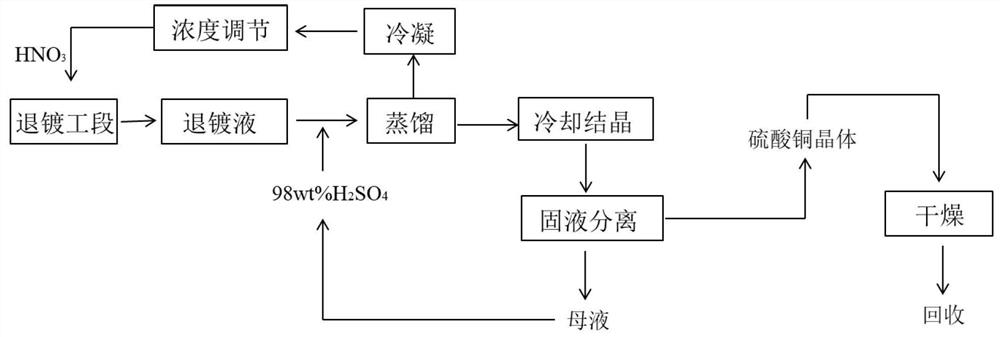

A technology for stripping waste liquid and copper sulfate, applied in copper sulfate, nitric acid, nitrogen oxides/oxyacids, etc., can solve problems such as environmental pollution and waste of resources, achieve zero discharge, realize discharge, and improve reuse value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

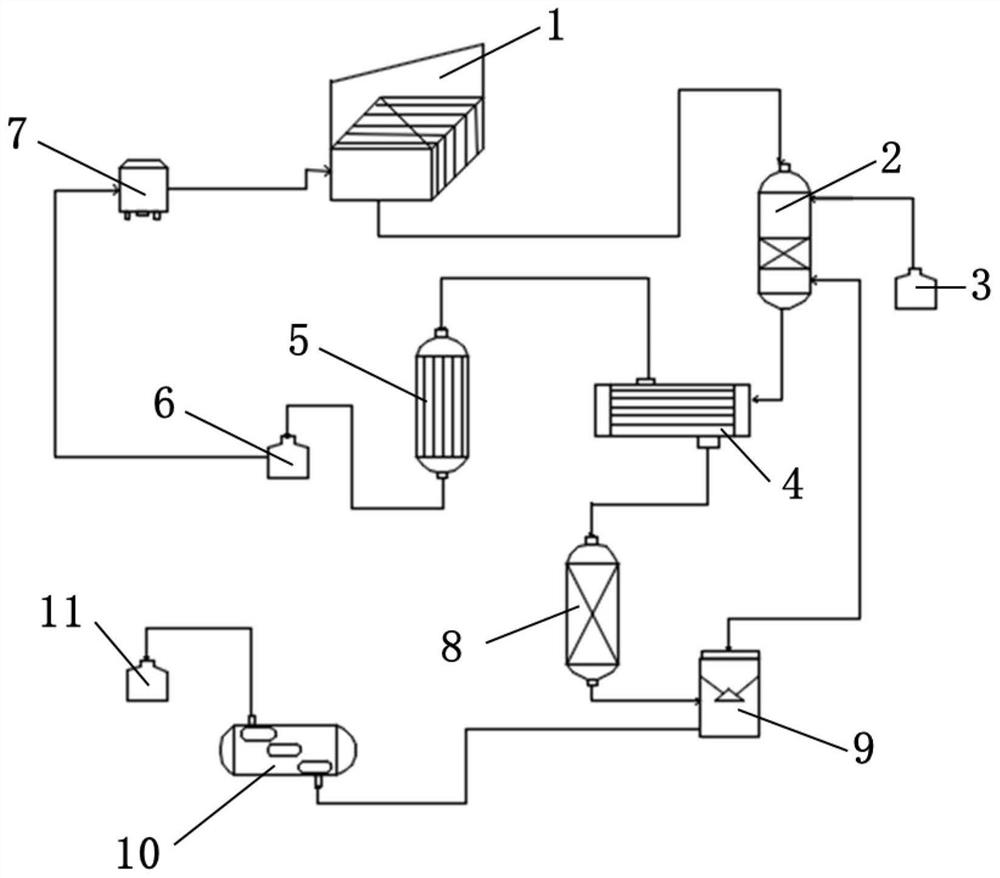

Method used

Image

Examples

Embodiment 1

[0062] Get 2L of stripping waste solution in the present embodiment and carry out the experiment of reclaiming nitric acid and copper sulfate, and its concrete steps are as follows:

[0063] (1) Put the stripping waste liquid of 1L in the 2L distillation bottle, place the distillation bottle on the magnetic heating stirrer, add 98wt% concentrated sulfuric acid to it while stirring, ensure that the mole number of sulfuric acid in the solution is the copper ion mole 2 times the number, stir and mix for 30 minutes, the temperature of the mixture rises to 58 ° C, heat distillation, nitric acid is vaporized and condensed at 10 ° C, the concentration of the nitric acid condensate is adjusted to 45%, and then sent to the retreat Plating section, collecting residual liquid;

[0064] (2) Cooling the distilled raffinate in step (1) for 2 hours at 10° C., stirring and crystallizing to separate out copper sulfate crystals, and then separating the mother liquor through solid-liquid separat...

Embodiment 2

[0068] Get 2L of stripping waste solution in the present embodiment and carry out the experiment of reclaiming nitric acid and copper sulfate, and its concrete steps are as follows:

[0069] (1) Put the stripping waste liquid of 1L in the 2L distillation bottle, place the distillation bottle on the magnetic heating stirrer, add 98wt% concentrated sulfuric acid to it while stirring, ensure that the mole number of sulfuric acid in the solution is the copper ion mole 1.8 times the number, stir and mix for 25 minutes, the temperature of the mixed liquid rises to 55°C, heats up to 115°C for distillation, condenses at 15°C after the nitric acid is vaporized, adjusts the concentration of the nitric acid condensate to 40%, and then sends Enter the deplating section to collect the residual liquid after distillation;

[0070] (2) cooling the distilled raffinate in step (1) for 3 h at 15° C., stirring and crystallizing, and separating out copper sulfate crystals, and then separating the ...

Embodiment 3

[0074] Get 2L of stripping waste solution in the present embodiment and carry out the experiment of reclaiming nitric acid and copper sulfate, and its concrete steps are as follows:

[0075] (1) Put the stripping waste liquid of 1L in the 2L distillation bottle, place the distillation bottle on the magnetic heating stirrer, add 98wt% concentrated sulfuric acid to it while stirring, ensure that the mole number of sulfuric acid in the solution is the copper ion mole 1.6 times the number, stir and mix for 35 minutes, the temperature of the mixed liquid rises to 60 ° C, heat distillation, nitric acid is vaporized and condensed at 18 ° C, the concentration of the nitric acid condensate is adjusted, the mass fraction of nitric acid reaches 50%, and then sent to the retreat Plating section, collecting residual liquid;

[0076] (2) Cooling the distilled raffinate in step (1) for 2 hours at 10° C., stirring and crystallizing to separate out copper sulfate crystals, and then separating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com