Electrocatalytic biological aerated filter and wastewater aeration method

The technology of aeration biological filter and aeration method is applied in the field of electrocatalytic aeration biological filter and wastewater aeration, which can solve the problems of limited treatment degree of refractory industrial wastewater, incomplete treatment of refractory industrial wastewater, etc. To achieve the effect of improving the biodegradability of sewage and the complete treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Equipment condition:

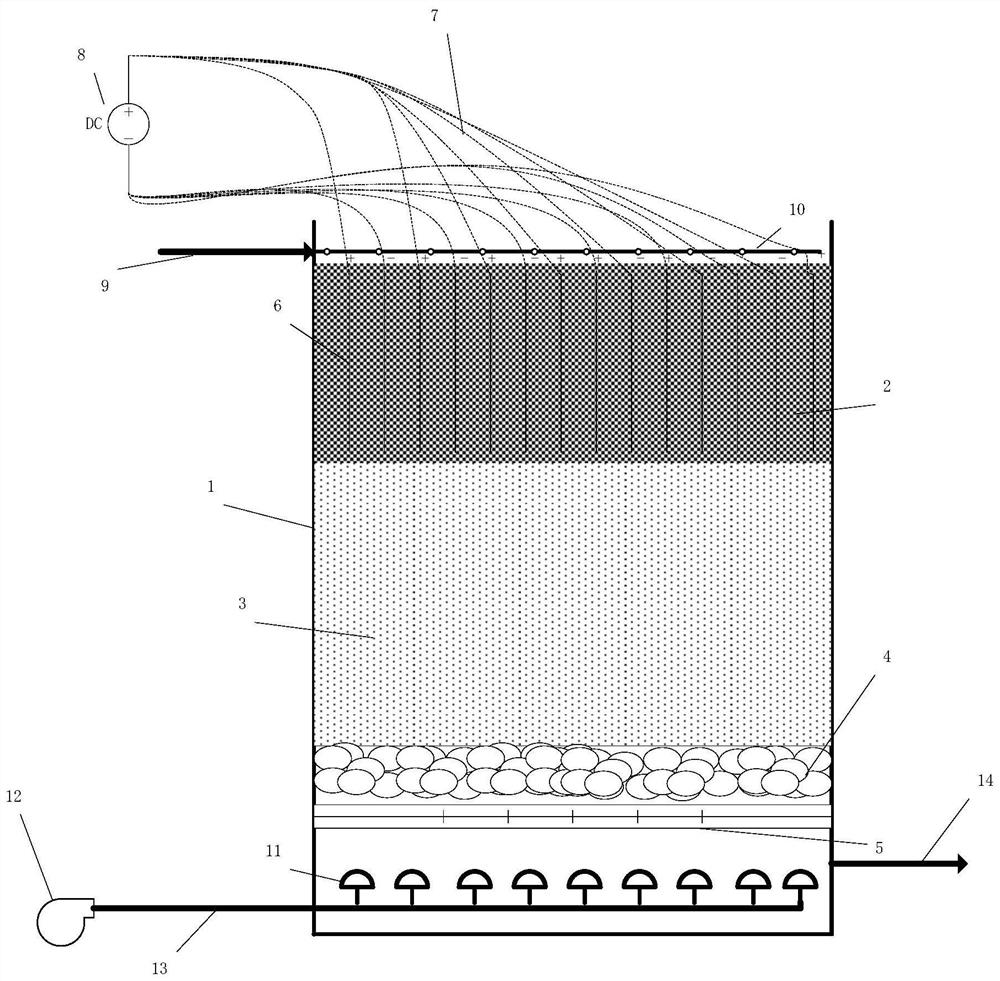

[0099] Catalyst layer 2: The filler is filled with FCC waste catalyst. The filler is obtained by roasting FCC waste catalyst at 500°C to remove oil, then washing with demineralized water to remove salt, drying at 100°C and crushing to a specified particle size. ; Catalyst layer filler particle size 3-4mm.

[0100] Biological filler layer 3: The filler is filled with volcanic rock, the particle size of the volcanic rock is 2-3cm, and the density is 1.9-2.3g / cm 3 , specific surface area 8×10 4 -9×10 4 cm 2 / g, the filling porosity is 60%, and the intragranular porosity is 25%.

[0101] Physical filler layer 4: the filler is filled with pebbles, and the particle size of the pebbles is 4-6cm.

[0102] Multi-hole plate 5: the hole diameter is 2.5 cm.

[0103] Operating parameters:

[0104] Hydraulic retention time: biological filler layer 3h, catalyst layer 2h, air-water ratio (volume ratio) 5:1, plate spacing 10cm, current density 50mA / cm 2 ; ...

Embodiment 2

[0108] Equipment condition is identical with embodiment 1.

[0109] Operating parameters:

[0110] Hydraulic retention time: biological filler layer 3h, catalyst layer 2h, air-water ratio (volume ratio) 7:1, electrode plate spacing 5cm, current density 70mA / cm 2 ;

[0111] Raw water treatment: biochemical effluent from refined oil depot, COD: 119mg / L, petroleum 3mg / L;

[0112] Treated water: COD: 78mg / L, petroleum 0.5mg / L.

Embodiment 3

[0114] Equipment condition is identical with embodiment 1.

[0115] Operating parameters:

[0116] Hydraulic retention time: biological filler layer 3h, catalyst layer 2h, air-water ratio (volume ratio) 5:1, plate spacing 10cm, current density 50mA / cm 2 ;

[0117] Raw water treatment: biochemical effluent from refinery sewage treatment plant, COD: 123mg / L, BOD5: 28mg / L, ammonia nitrogen: 8mg / L, petroleum: 3mg / L;

[0118] Treated water: COD: 75mg / L, BOD5: 16mg / L, ammonia nitrogen: 2mg / L, petroleum: 0.9mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com