High-strength quartz sand fine-powder aerated brick and production process thereof

A production process, quartz sand technology, applied in the field of aerated bricks, can solve the problems of less than 20% comprehensive utilization rate, occupying land, wasting resources, etc., and achieve the effects of enhancing strength, rational utilization and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

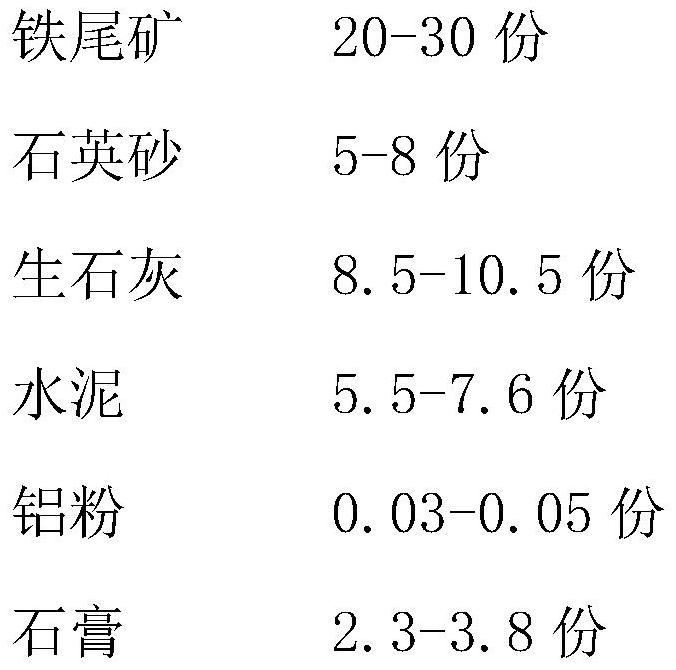

[0026] A high-strength aerated brick made of quartz sand fine powder, prepared from the following materials in parts by weight:

[0027]

[0028] A production process of quartz sand fine powder high-strength aerated bricks, the steps are as follows:

[0029] S1. Iron tailings and quartz sand are sent to the ball mill through electromagnetic vibration feeder and belt conveyor. The finely ground iron tailings and quartz sand are sent to the powder batching bin respectively, and quicklime and gypsum are fed by electromagnetic vibration. Machine and belt conveyor are sent to the jaw crusher for crushing, and then sent to the ball mill through the screw conveyor. The ground materials are sent to the batching bin through the screw conveyor and bucket elevator respectively, while the cement and aluminum powder are directly crushed. Import into the batching bin;

[0030] S2. Iron tailings, quartz sand, quicklime, cement, aluminum powder and gypsum are sequentially sent to the auto...

Embodiment 2

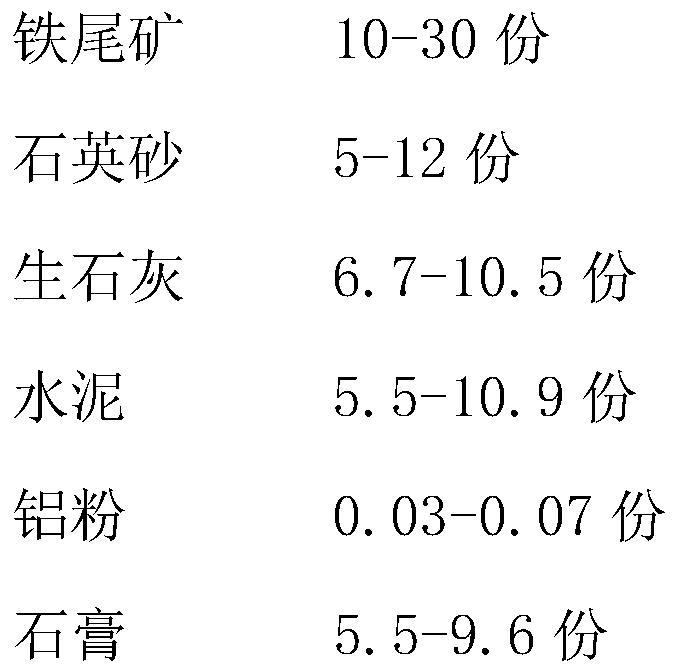

[0036] A high-strength aerated brick made of quartz sand fine powder, prepared from the following materials in parts by weight:

[0037]

[0038] A production process of quartz sand fine powder high-strength aerated bricks, the steps are as follows:

[0039] S1. Iron tailings and quartz sand are sent to the ball mill through electromagnetic vibration feeder and belt conveyor. The finely ground iron tailings and quartz sand are sent to the powder batching bin respectively, and quicklime and gypsum are fed by electromagnetic vibration. Machine and belt conveyor are sent to the jaw crusher for crushing, and then sent to the ball mill through the screw conveyor. The ground materials are sent to the batching bin through the screw conveyor and bucket elevator respectively, while the cement and aluminum powder are directly crushed. Import into the batching bin;

[0040] S2. Iron tailings, quartz sand, quicklime, cement, aluminum powder and gypsum are sequentially sent to the auto...

Embodiment 3

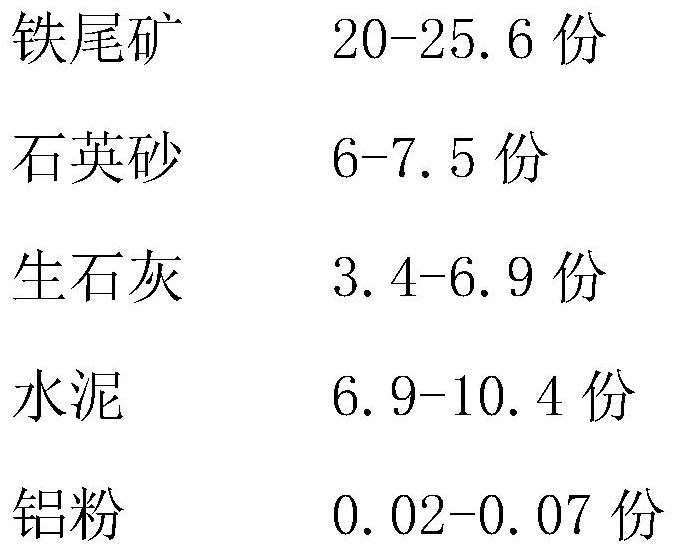

[0046] A high-strength aerated brick made of quartz sand fine powder, prepared from the following materials in parts by weight:

[0047]

[0048] A production process of quartz sand fine powder high-strength aerated bricks, the steps are as follows:

[0049]S1. Iron tailings and quartz sand are sent to the ball mill through electromagnetic vibration feeder and belt conveyor. The finely ground iron tailings and quartz sand are sent to the powder batching bin respectively, and quicklime and gypsum are fed by electromagnetic vibration. Machine and belt conveyor are sent to the jaw crusher for crushing, and then sent to the ball mill through the screw conveyor. The ground materials are sent to the batching bin through the screw conveyor and bucket elevator respectively, while the cement and aluminum powder are directly crushed. Import into the batching bin;

[0050] S2. Iron tailings, quartz sand, quicklime, cement, aluminum powder and gypsum are sequentially sent to the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com