Purification method of crude hydroxyethyl hydrazine nitrate

A technology of hydroxyethylhydrazine and purification method, which is applied in the preparation of hydrazine, organic chemistry, etc., can solve the problems of high time consumption, discoloration, restriction of synthesis production process efficiency and product quality, and achieve product color improvement, short evaporation time, Effect of storage stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

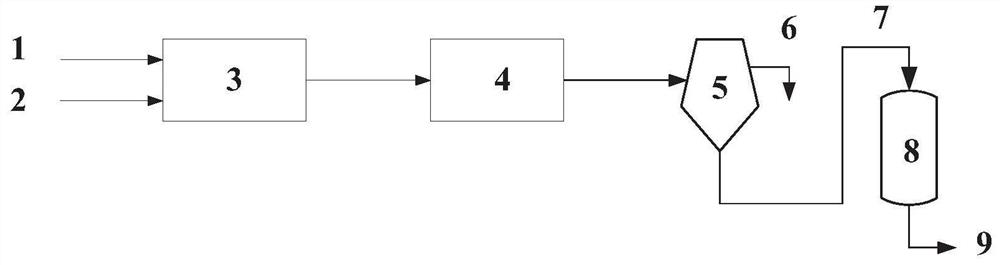

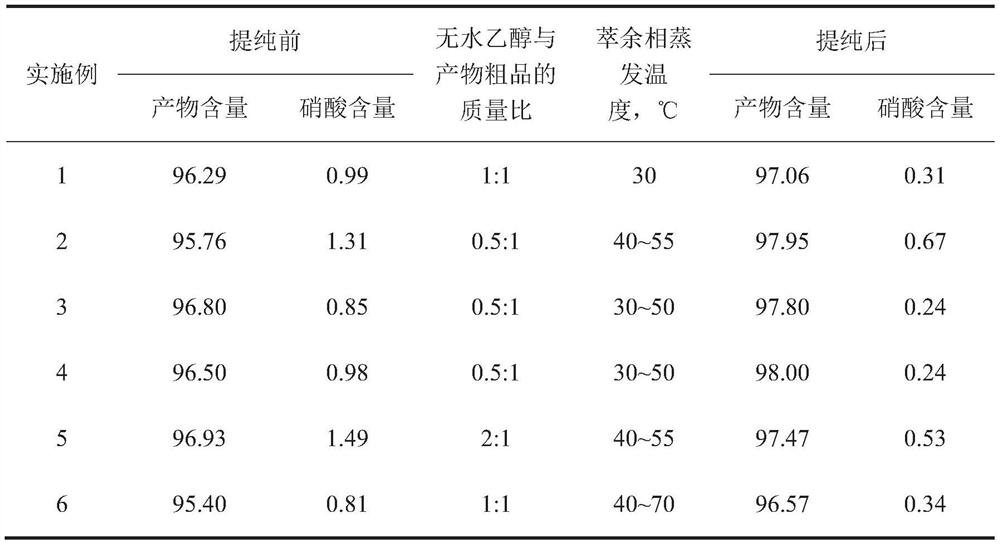

[0033] Embodiment 1-6, continuous reaction-intermittent extraction-separation-evaporation

[0034] Continuous synthesis of hydroxyethylhydrazine nitrate crude product: two metering pumps are used to continuously feed concentrated nitric acid (mass concentration 66.6%) and 99% hydroxyethylhydrazine raw materials into the microchannel reactor according to the reaction molar ratio of 1:1. Control the reaction temperature and reaction time during the reaction to obtain the crude product of hydroxyethylhydrazine nitrate.

[0035] Extraction, separation and evaporation of the crude product of hydroxyethylhydrazine nitrate: weigh the crude product, add absolute ethanol according to the mass ratio required by the process, and make the two form a mixed system in the container at room temperature, and the absolute ethanol and the aqueous phase of the crude product (comprising water in raw material concentrated nitric acid and unreacted trace nitric acid) combined to complete the mixed e...

Embodiment 7

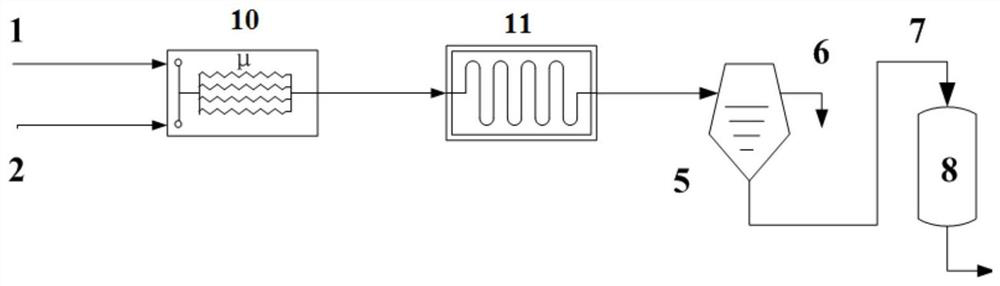

[0039] Embodiment 7, continuous reaction-continuous extraction-continuous separation

[0040] Use two metering pumps to continuously feed concentrated nitric acid (66.6% mass concentration) and 99% hydroxyethylhydrazine raw materials into the first microchannel reactor at a reaction molar ratio of 1:1 for reaction, and control the reaction temperature and reaction time during the reaction , the product reacted by the first microchannel reactor flows through the first microchannel heat exchanger and is cooled to normal temperature to obtain a colorless crude product, which is continuously passed into the microchannel mixer 10 with the extractant absolute ethanol to form a mixed system , carry out the extraction and mass transfer process at normal temperature, the flow rate of the extraction agent is controlled by the third metering pump according to the set ratio; then, the mixed system is continuously passed into the second microchannel heat exchanger 11 for cooling, and then l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com