Self-aligned pattern process method

A process method and self-alignment technology, applied in electrical components, transistors, electrical solid devices, etc., can solve problems such as micro pattern size failure and structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

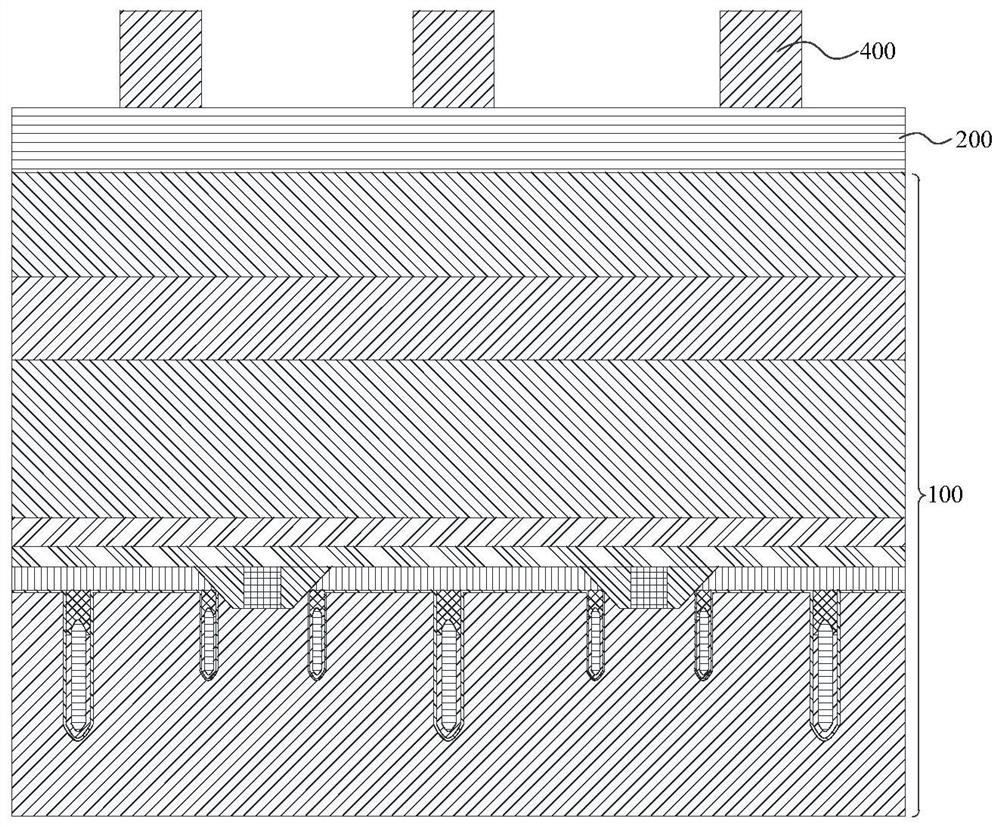

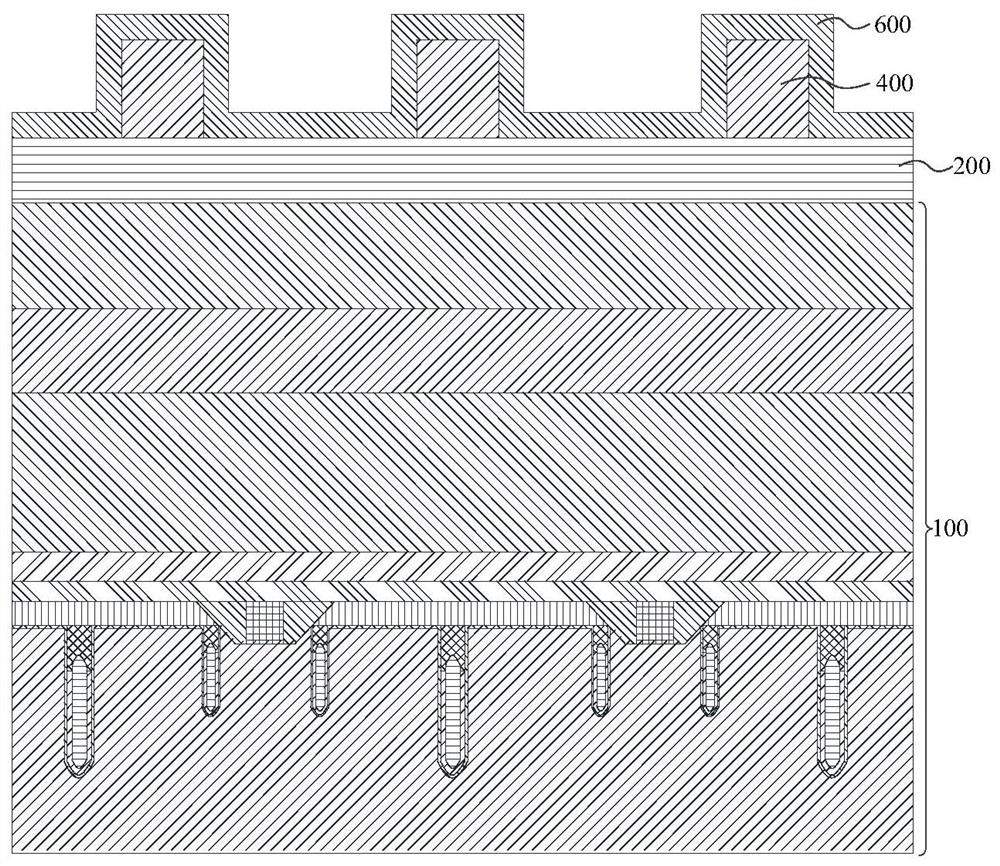

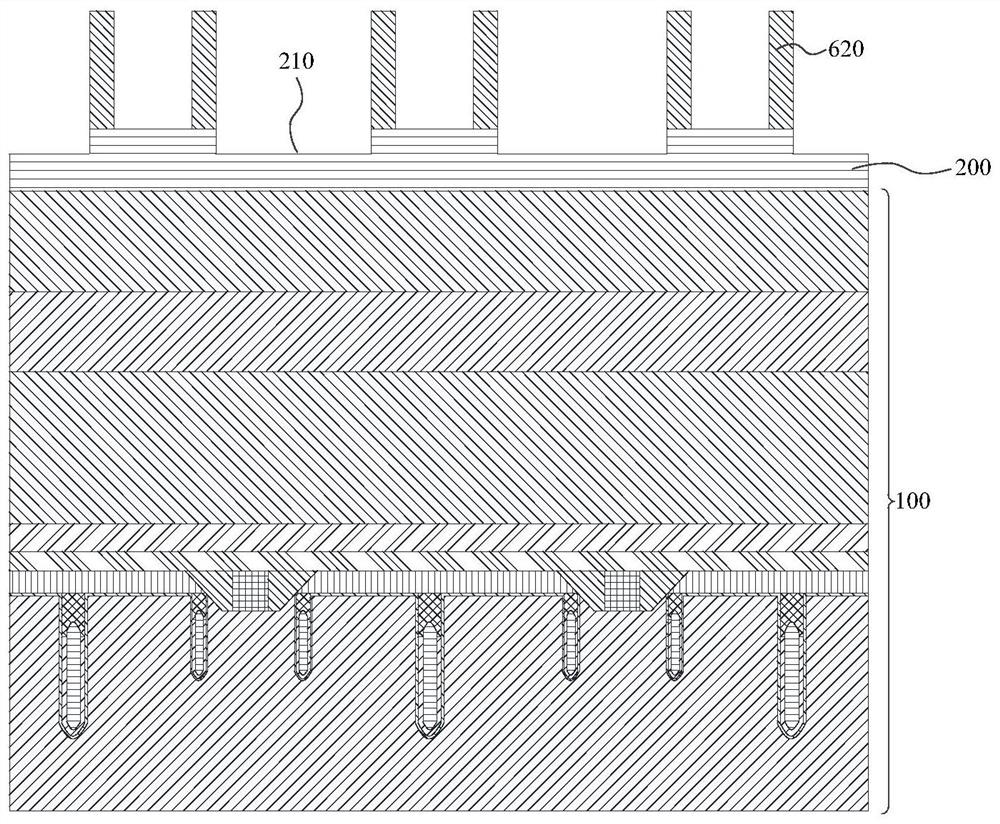

[0054] In related technologies, see Figure 1 to Figure 3 As shown, the self-aligned pattern process method includes the following steps: sequentially forming a stacked first hard mask layer 200, a sacrificial layer 400 and a photoresist layer 800 on the target layer 100, and patterning the photoresist layer 800; The patterned photoresist layer 800 is a mask, and part of the sacrificial layer 400 is removed to expose the first hard mask layer 200. The sacrificial layer 400 remaining on the first hard mask layer 200 forms a plurality of sacrificial patterns. forming a first sidewall material layer 600 on the mask layer 200 and the sacrificial pattern; The first sidewall material layer 600 on the top of the film layer 200, retaining the first sidewall material layer 600 on the sidewall of each sacrificial pattern; removing the sacrificial layer 400 in each sacrificial pattern, exposing the first hard mask in each sacrificial pattern layer 200 to form a plurality of first sidewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com