Preparation method of tea leaf cell water and application of obtained tea leaf cell water

A cell and tea technology, which is applied to the preparation of tea cell water and the application field of tea cell water, can solve the problems of complicated operation, uncontrollable quality, and low extraction amount, so as to speed up the extraction efficiency and avoid the problem of excessive enzymatic hydrolysis. Scented effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

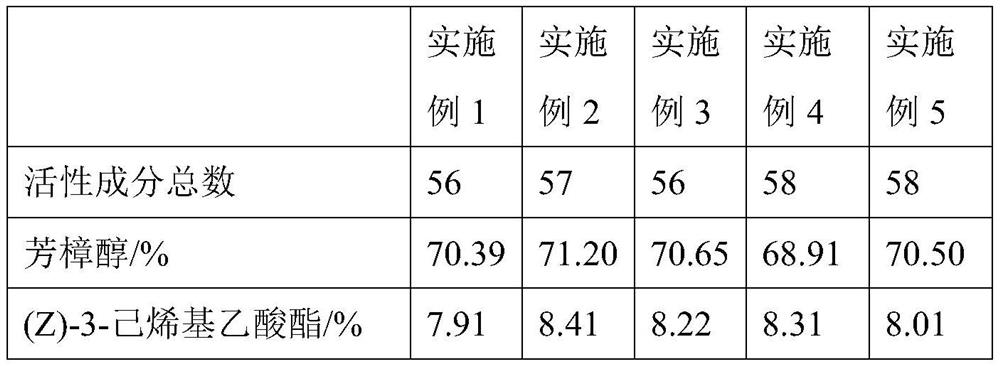

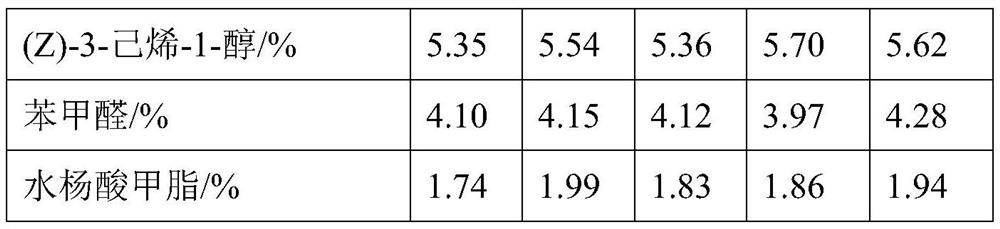

Embodiment 1

[0022] Example 1: Without adding solvent, 50kg of tea leaves were preliminarily extracted at 50°C and a pressure of -85kPa, the tea cell water formed steam and condensed to collect the liquid, extracted for 1.5 hours, and the initial extraction cell water and the initial extraction tea residue were obtained; Add 100g cellulase and 20g pectinase to the cell water, then add the primary cell water to the primary tea residue, extract again at 50°C and pressure -81kPa, after 6 hours of extraction, the whole process is stirred at 60 rpm , condensing temperature -8°C, 35.5kg of tea cell water was collected, the tea fragrance was strong, and the cell fluid was clear and transparent.

Embodiment 2

[0023] Example 2: Without adding solvent, 50kg of tea leaves were preliminarily extracted at 65°C and a pressure of -70kPa, the tea cell water formed steam and condensed to collect the liquid, extracted for 1.5 hours, and the initial extraction cell water and the initial extraction tea residue were obtained; Add 100g cellulase and 20g pectinase to the cell water, then add the primary cell water to the primary tea residue, extract again at 50°C and pressure -81kPa, after 6 hours of extraction, the whole process is stirred at 60 rpm , the condensation temperature is -8°C, and 35.2kg of tea cell water is collected. The tea has a strong fragrance and the cell fluid is clear and transparent.

Embodiment 3

[0024] Example 3: Without adding solvent, 50kg of tea leaves were initially extracted at 40°C and a pressure of -85kPa, the tea cell water formed steam and condensed to collect the liquid, and extracted for 1.5 hours to obtain the initial extraction cell water and the initial extraction tea residue; Add 100g cellulase and 20g pectinase to the cell water, then add the primary cell water to the primary tea residue, extract again at 50°C and pressure -81kPa, after 6 hours of extraction, the whole process is stirred at 60 rpm , condensing temperature -8°C, 34.8kg of tea cell water was collected, the tea fragrance was strong, and the cell fluid was clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com