Modified manganese dioxide with high specific surface area, preparation method and application thereof

A manganese dioxide, modified technology, applied in the field of two-dimensional materials, can solve the problems of low mineralization rate and easy deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

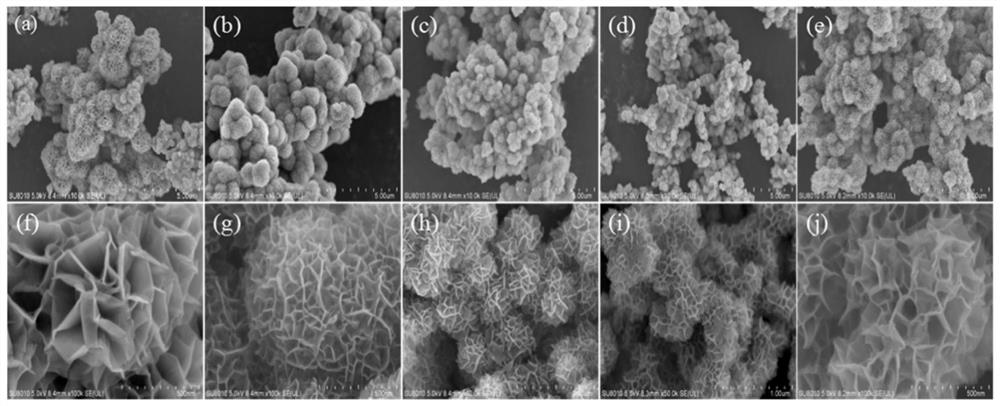

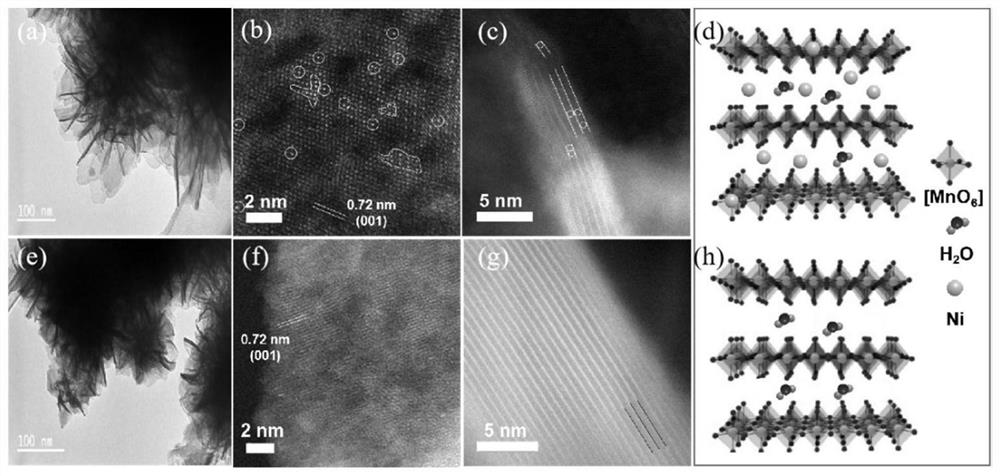

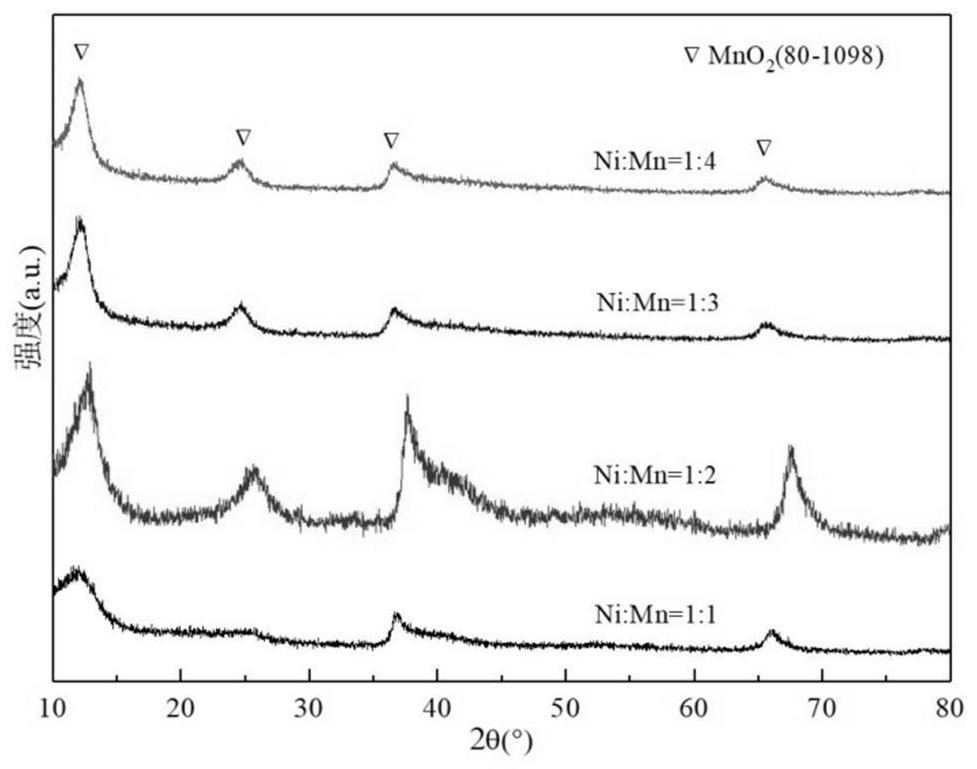

[0044] This embodiment provides a Ni / δ-MnO 2 , the Ni / δ-MnO 2 In Ni:Mn=1:2, the Ni / δ-MnO 2 The preparation method is as follows:

[0045] Weigh 1.500g (0.0095mol) KMnO 4 and 0.720g (0.00555mol) NiCl 2 Dissolve in an appropriate amount of deionized water to obtain a mixed solution;

[0046] Weigh 0.275g (0.0016mol) MnSO 4 ·H 2 O is dissolved in an appropriate amount of deionized water to obtain a manganese sulfate solution;

[0047] Add the manganese sulfate solution to the mixed solution and mix evenly, stir it magnetically, transfer it to a reaction kettle, and conduct a hydrothermal reaction at 160°C for 24 hours, cool, filter, wash, and dry to obtain Ni / δ-MnO 2 .

Embodiment 2

[0049] This embodiment provides a Ni / δ-MnO 2 , the Ni / δ-MnO 2 The difference between the preparation method and Example 1 is only that NiCl 2 The amount of 0.480g (0.0037mol, Ni:Mn=1:3).

Embodiment 3

[0051] This embodiment provides a Ni / δ-MnO 2 , the Ni / δ-MnO 2 The difference between the preparation method and Example 1 is only that NiCl 2 The amount of 0.360g (0.002775mol, Ni:Mn=1:4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com