Preparation method of deuterated ammonia and deuteration reaction participated by deuterated ammonia as deuterium source

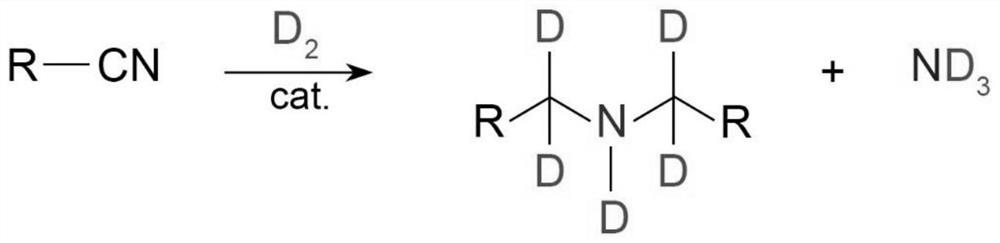

A deuterium and reaction technology, applied in the field of deuterated ammonia preparation and deuterated reaction, can solve the problems of high price and high energy consumption, and achieve the effects of low operating cost and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

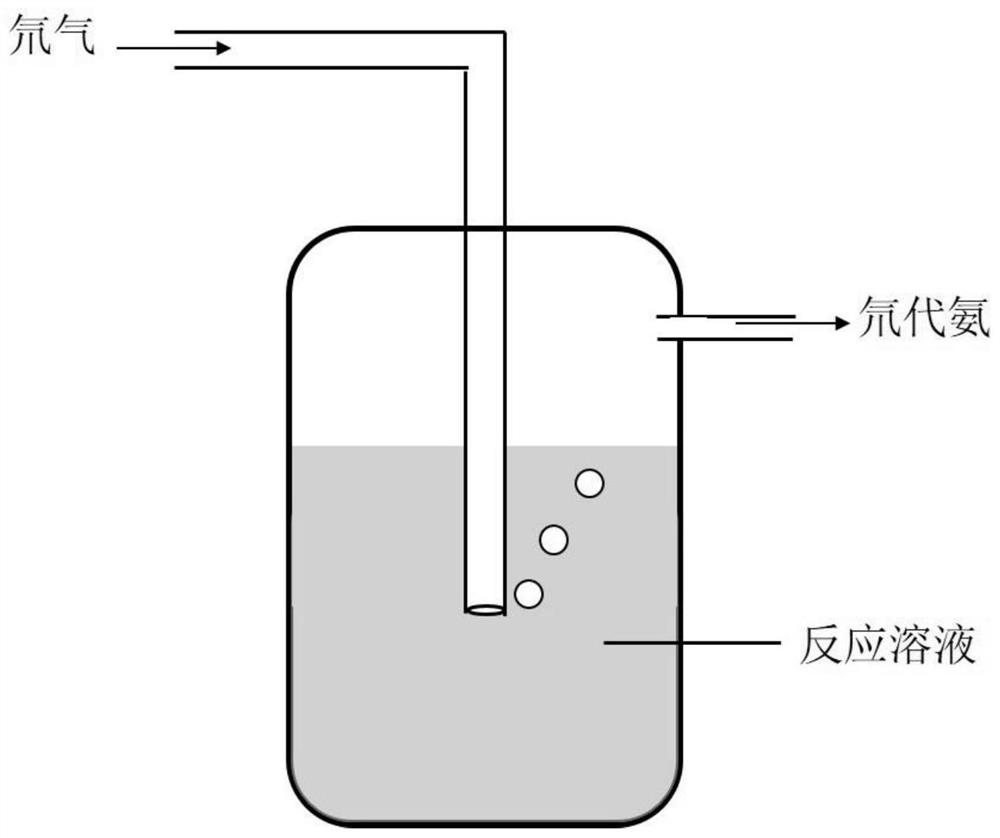

Method used

Image

Examples

Embodiment 1

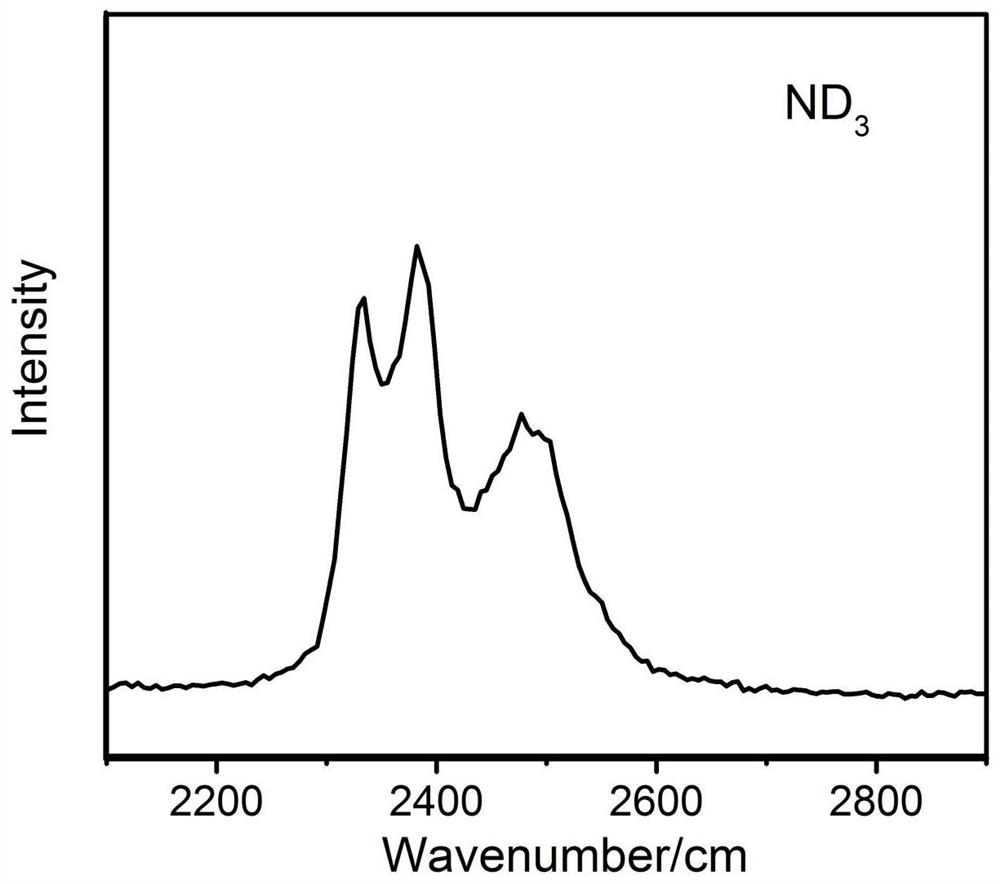

[0032] Get benzonitrile (0.5mmol), platinum nanowire (0.025mmol) and mix in 2mL deuterated methanol, pass into 2mmol deuterium gas, 40 ℃ stirring reaction for 4 hours, produce 0.23mmol deuterated ammonia, deuterated ammonia production rate is 92%. pass image 3 In the Raman test, it can be confirmed that the obtained is deuterated ammonia.

Embodiment 2

[0034] Take p-ethylbenzonitrile (0.5mmol) and platinum nanorods (0.05mmol) and mix them in 2mL deuterated benzene, pass through 2mmol ml of deuterium gas, stir and react at 50°C for 6 hours to produce 0.21mmol deuterated ammonia, deuterated Ammonia yield was 84%.

Embodiment 3

[0036] Take p-chlorobenzonitrile (1mmol) and palladium nanowires (0.05mmol) and mix them in 2mL of deuterated benzene, feed 3mmol of deuterium gas, stir and react at 35°C for 10 hours to produce 0.43mmol of deuterated ammonia, and the yield of deuterated ammonia is was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com