Amino-functionalized polystyrene resin as well as preparation method and application thereof

A technology of polystyrene resin and amine group, applied in the field of amine functionalized polystyrene resin and its preparation, can solve the problems of complicated preparation method, unfavorable industrial production, increase of reaction steps, etc., and achieve simple process and excellent preparation process Safety and environmental protection, highly adjustable amine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The second aspect of the present invention is to provide the preparation method of the amino-functionalized polystyrene resin described in the first aspect of the present invention, the preparation method comprising the following steps:

[0056] Step 1. Mix the weighed N-vinylamide monomer, styrene monomer, initiator, crosslinking agent and solvent, and heat up to react;

[0057] Step 2, hydrolyzing the product obtained in step 1;

[0058] In step 3, the hydrolyzed product is washed and dried to obtain the final product.

[0059] The steps are described and illustrated in detail below.

[0060] Step 1. Mix the weighed N-vinylamide monomer, styrene monomer, initiator, crosslinking agent and solvent, and heat up to react;

[0061] In the present invention, the N-vinyl formamide monomer has a structure shown in formula (1):

[0062]

[0063] Among them, the substituent R 1 , R 3 Each is independently selected from one of hydrogen, alkyl, branched alkyl, phenyl and ...

Embodiment 1

[0099] Take 1.2g of N-vinylformamide, 0.8g of styrene, 0.03g of azobisisobutyronitrile and 8g of N,N-dimethylformamide and add them to a reactor equipped with a stirring device and a nitrogen pipe, and mix them evenly , to obtain a homogeneous mixed solution, stirred for 30 min with nitrogen, heated to 70 °C, stirred for 12 h, taken out, washed, precipitated, and centrifuged for 3 times, added 10 g of 0.1 mol / L sodium hydroxide aqueous solution, and hydrolyzed at 50 °C for 12 hours, precipitated, centrifuged, washed with water until neutral, and then freeze-dried to obtain the product.

Embodiment 2

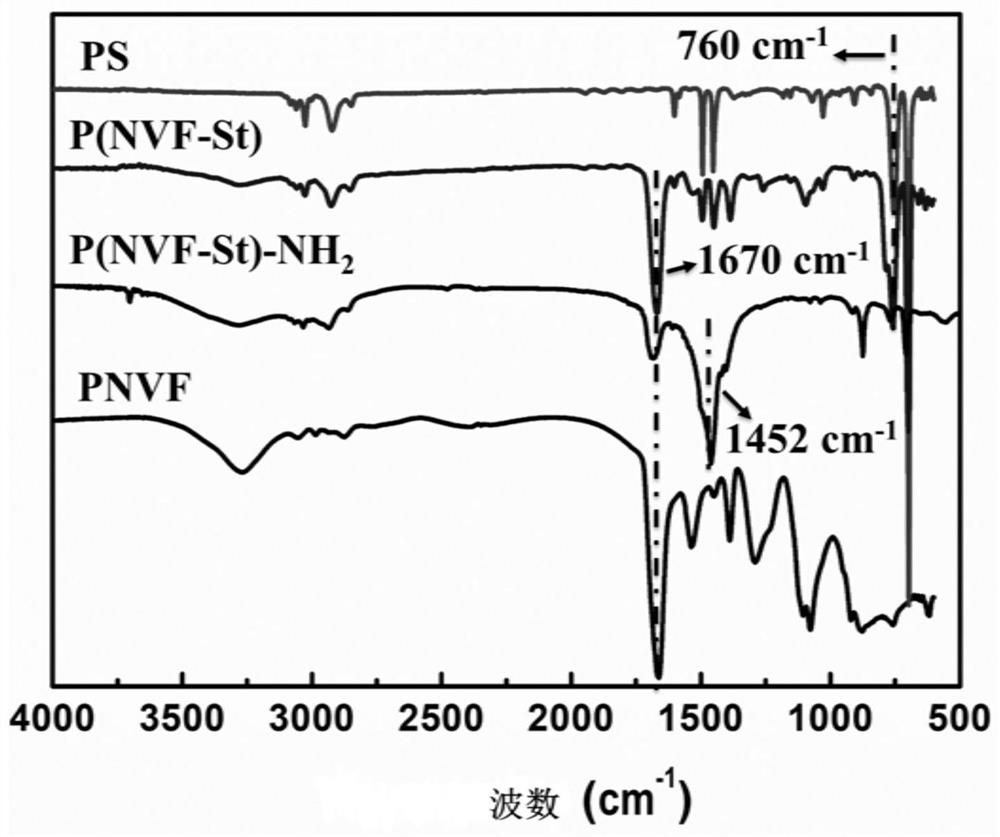

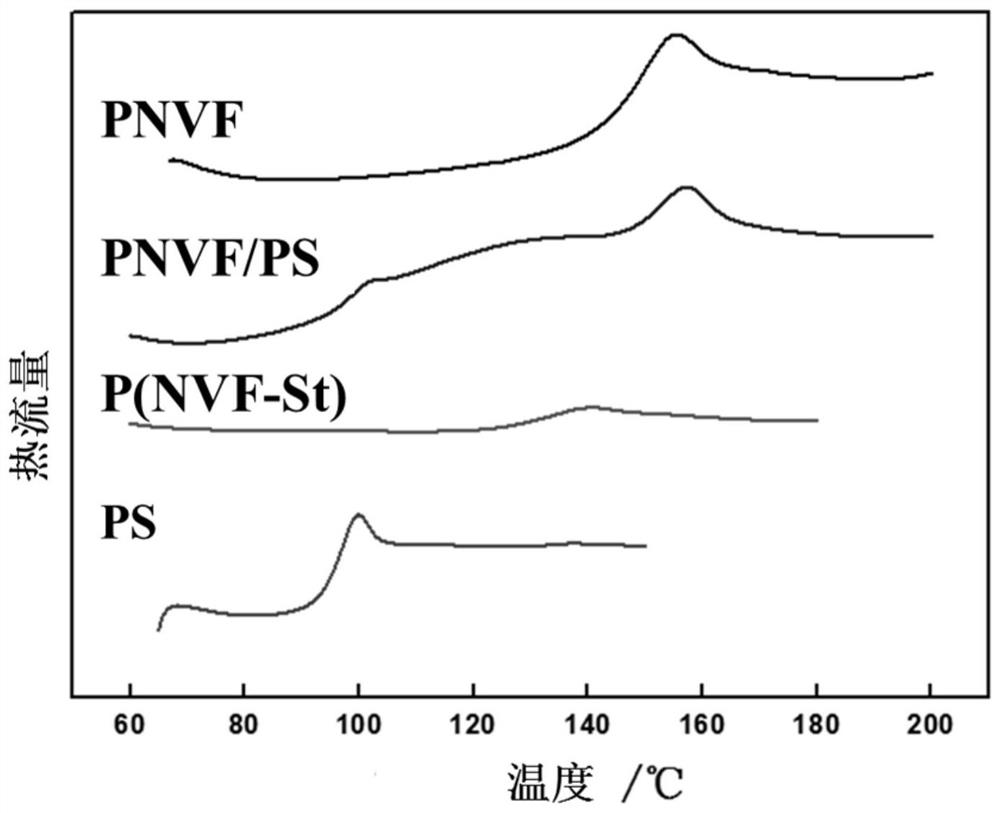

[0101] Take 1.5g of N-vinylformamide, 0.5g of styrene, 0.03g of azobisisobutyronitrile and 2g of N,N-dimethylformamide and add them to the reactor equipped with a stirring device and a nitrogen pipe, and mix them evenly , obtain a homogeneous mixed solution, stir for 30min with nitrogen, heat up to 70°C, stir and react for 12h, take out the material, wash, precipitate, centrifuge 3 times, freeze-dry to obtain polystyrene copolymer (P(NVF-St )), its infrared spectrum see figure 1 , DSC curve see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com