Method and system for automatically pouring slag in converter slag remaining process

A converter and slag pouring technology is applied in the improvement of process efficiency, steel manufacturing technology, metal processing and other directions to achieve the effect of improving the success rate of slag pouring, improving the working environment and reducing the probability of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

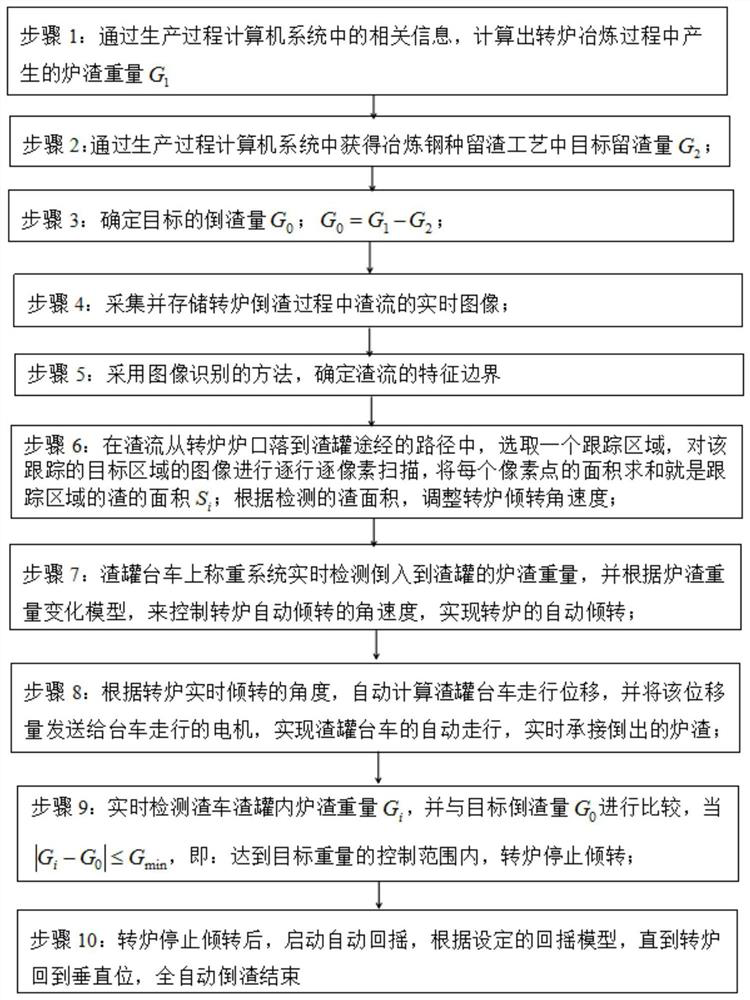

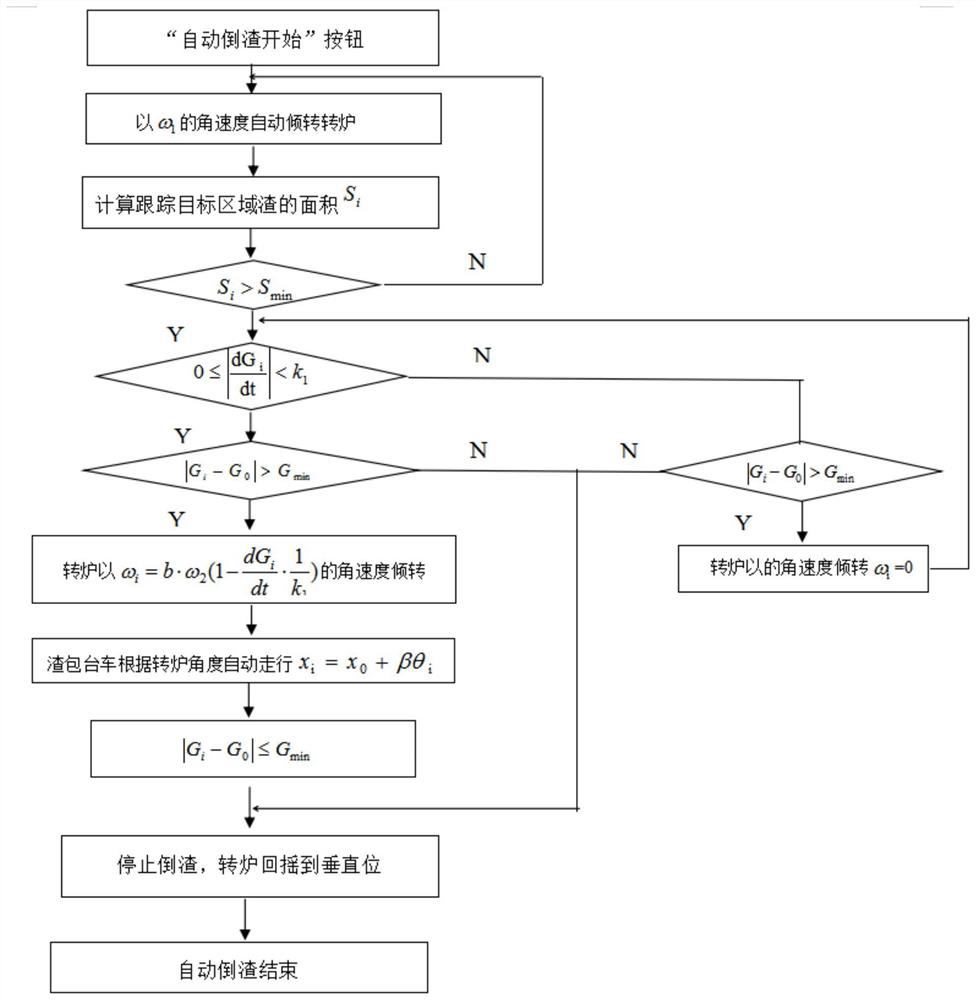

[0059] The method and system of automatic restraint of the converter rocking process according to the present invention will be further described below, and the description does not constitute an illustrative defined in the present invention.

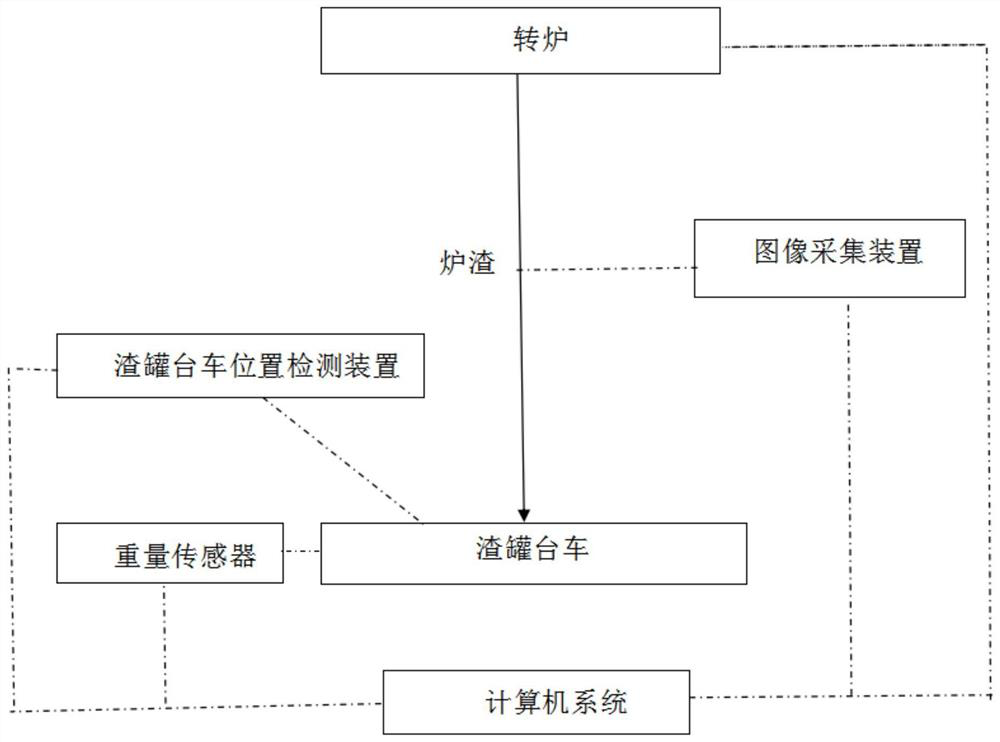

[0060] figure 1 The structure of the automatic revert residue system according to the present invention is shown schematically in one embodiment.

[0061] like figure 1 As shown, in the present embodiment, the converter is connected to the converter tilting drive, and the converter tilt drive drives the converter to perform a residue action;

[0062] When the converter begins to restock, the conversion is tilted so that the converter can pillen from the vertical position to a residue position where a certain angle is formed, and the angle angle can be measured by the converter inclination measuring device, measuring the converter inclination angle of the converter angle. Measurement The device can include an encoder or an inclinationer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com