Semiconductor structure and forming method thereof

A semiconductor and graphics technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device components, etc., it can solve problems such as having a great impact on performance and affecting the normal operation of semiconductor devices, improving electrical performance and avoiding engraving. Over-etching or under-etching, resulting in good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Currently formed devices still suffer from poor performance. The reasons for the poor performance of the device are analyzed in conjunction with a method of forming a semiconductor structure.

[0031] refer to Figure 1 to Figure 5 , shows a structural schematic diagram corresponding to each step in a method for forming a semiconductor structure.

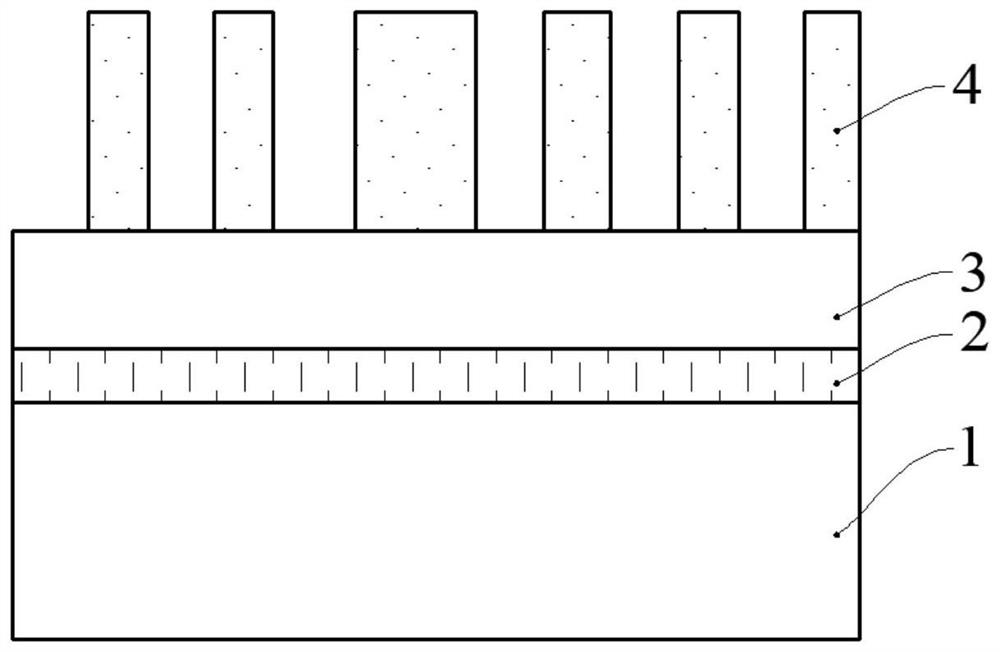

[0032] Such as figure 1As shown, a substrate 1, an anti-etching material layer 2 on the substrate 1 and a pattern definition layer 3 on the anti-etch material layer 2 are provided; a mask layer 4 is formed on the pattern definition layer 3 .

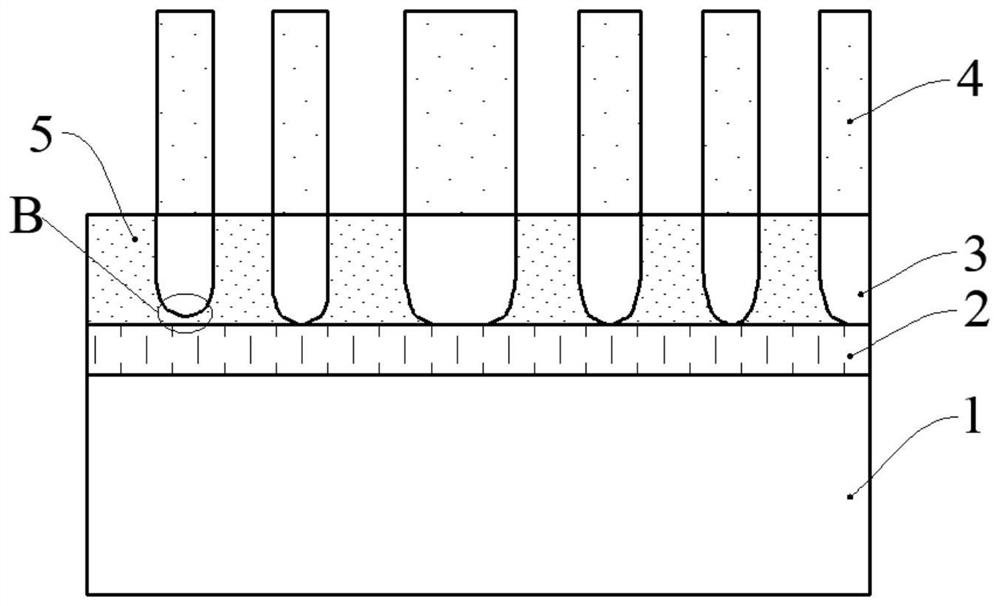

[0033] Such as figure 2 As shown, using the mask layer 4 as an implantation mask, doping ions in the pattern definition layer 3 between the mask layers 4 to form a doped layer 5, the resistance of the doped layer 5 The etch degree is greater than the etch resistance of the pattern definition layer 3 .

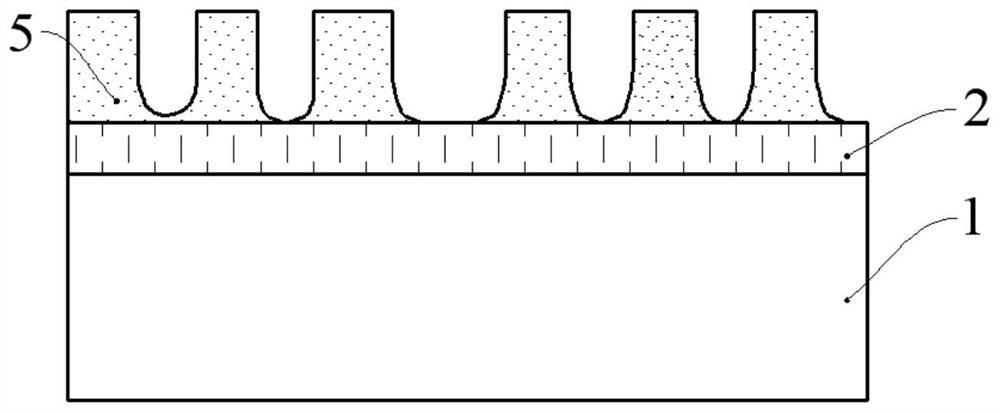

[0034] Such as image 3 As shown, after the doped layer 5 is formed, the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com