Full-automatic silicon carbide micro-powder wet grinding system and processing method thereof

A technology of silicon carbide micropowder and wet grinding, which is applied in the direction of grain processing, etc., can solve the problems of reducing the contact surface between grinding media and silicon carbide micropowder, affecting the grinding efficiency of silicon carbide micropowder, and failing to meet the particle size requirements, so as to improve grinding Efficiency and quality, improved grinding effect, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

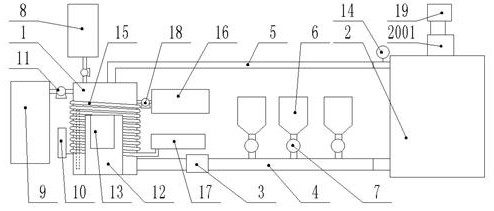

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0035] Such as figure 1 The full-automatic silicon carbide micropowder wet grinding system includes a circulation grinding module and a control module, through which the circulation grinding module realizes the grinding of the silicon carbide micropowder slurry, so that the silicon carbide micropowder reaches a specified size through grinding, and the circulation The grinding module is connected with a slurry concentration adjustment module, a slurry temperature adjustment module and a current adjustment module. The slurry concentration adjustment module includes a slurry fluidity adjustment module and a slurry pH adjustment module. The circulation grinding module, the slurry temperature adjustment module, the current adjustment module, the slurry fluidity adjustment module and the slurry pH adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com