A kind of extraction method and application of high-purity triterpene saponins

The technology of a triterpenoid saponin and an extraction method, which is applied in the field of daily chemical products, can solve the problems of high production cost of saponin, increase in production cost and the like, and achieve the effects of good impurity removal effect, simple and easy operation, and good extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

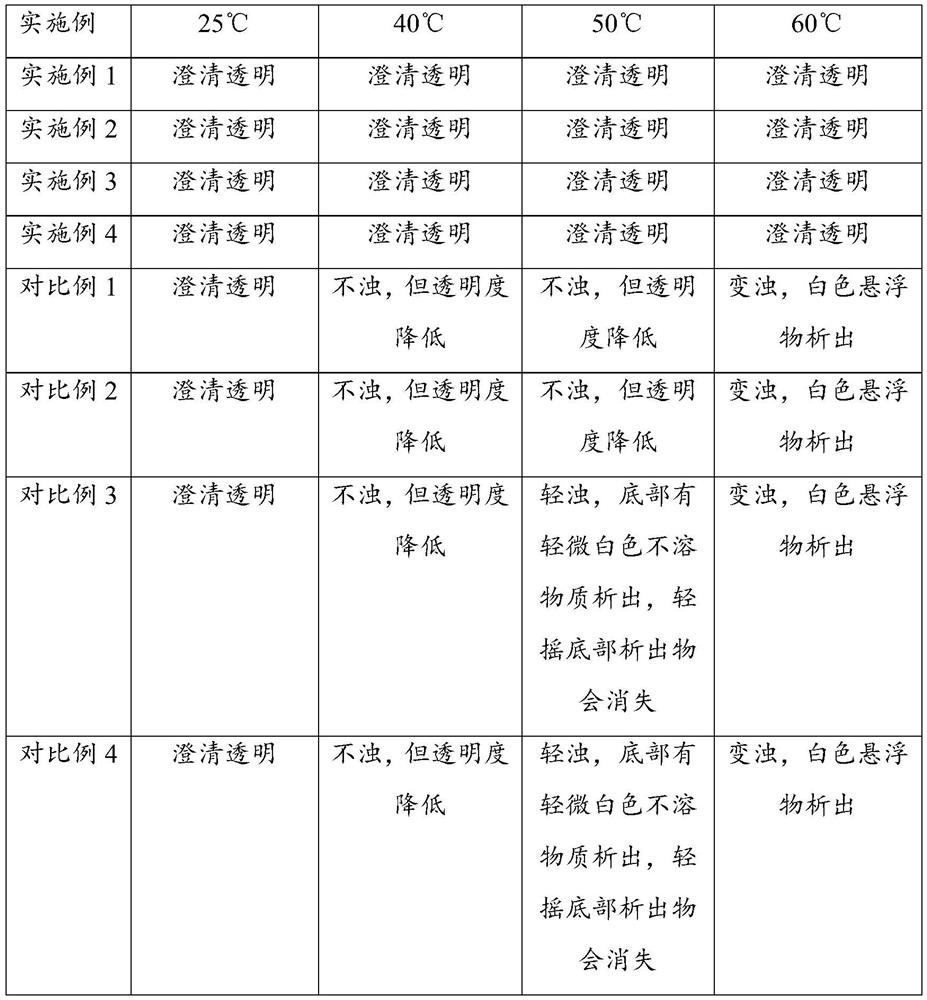

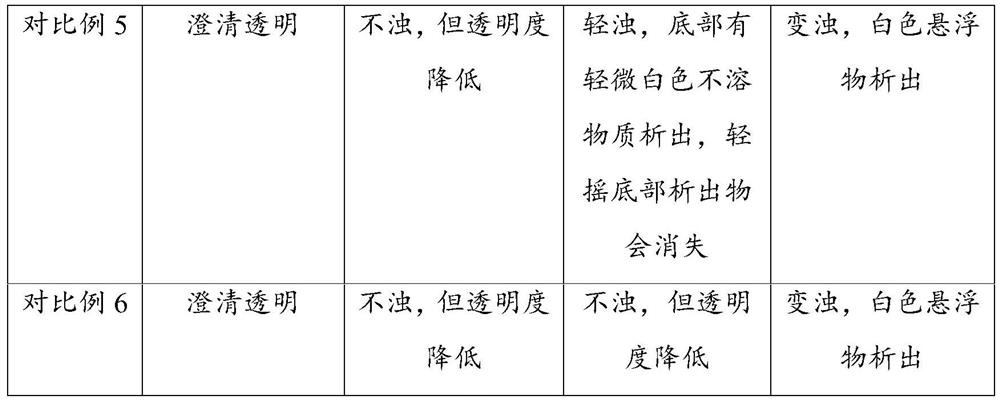

[0056] Embodiment 1 The first aspect provides a method for extracting high-purity triterpene saponins, the steps at least include the following steps: (1) Weigh 1000g of Sapindus sapindus pericarp, place it in a refrigerator at -2°C for 2 hours, and wait until After the pericarp was frozen hard, it was pulverized into 80 meshes to obtain Sapindus pericarp powder; (2) Add 2L of distilled water to Sapindus pericarp powder, stir at 70°C for 3 hours, and centrifuge to obtain 11.7L of initial extract and precipitation 1; precipitation 1 Add 2L of hot water at 70°C, heat and stir for 3 hours, centrifuge, first extract 2, and combine the first extract 1 and the first extract 2 to obtain 3.7L of initial extract; (3) Add 5g of flocculation aid to the initial extract, Stir for 4 hours at 70°C; then add 80 g of adsorption aids, stir at 70°C for 4 hours, centrifuge to obtain clarified liquid 1 and precipitate 2; add 1 L of distilled water to precipitate 2, stir at 70°C for 4 hours to obtai...

Embodiment 2

[0070] The specific implementation of the present embodiment is the same as that of Example 1, except that the mass ratio of dialkyl dimethyl ammonium chloride, anion polyacrylamide, polyaluminum and lauramide propyl hydroxysultaine is 1: 4:3:0.5.

Embodiment 3

[0072] The specific implementation of this example is the same as that of Example 1, except that 4 g of flocculation aids are added to the initial extract.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com