Waterborne anti-static epoxy floor paint and preparation method thereof

A technology of epoxy floor paint and anti-static ring, applied in epoxy resin coatings, conductive coatings, coatings, etc., can solve the problem of inability to increase anti-static properties, reduce mechanical properties of epoxy floor paint, and poor dispersion of conductive fillers and other problems, to achieve the effect of balancing emulsification and curing rates, improving mechanical properties, and increasing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

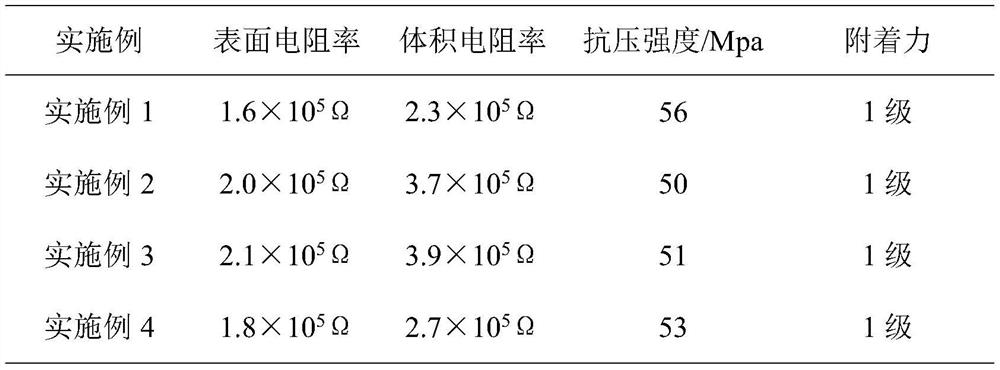

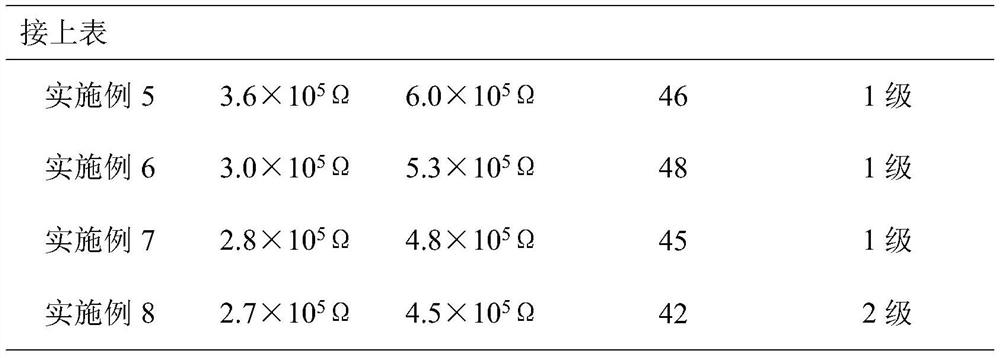

Examples

Embodiment 1

[0035] A preparation method of water-based antistatic epoxy floor paint, comprising the following steps:

[0036]S1: Preparation of composite conductive material: (1) Stir and disperse 21 parts of 3-aminopropyltriethoxysilane weighed in absolute ethanol, set the stirring speed to 400rmp, and stir for 40 minutes; add ammonia solution Adjust the pH to 10; add 46 parts of silica nanoparticles, react for 1 hour, centrifugally wash, filter, and dry at 55°C to obtain aminated silica for use; (2) ultrasonically disperse 8 parts of graphene oxide airgel In deionized water, add aminated silicon dioxide, set the stirring to 500rmp; add ammonia water, set the reaction temperature to 90°C and react for 5 hours, filter and wash, and freeze-dry at -50°C to obtain a composite conductive material for future use.

[0037] S2: Preparation of water-based epoxy curing agent; 12 parts of triethylenetetramine weighed are dissolved in 2-butoxyethanol and n-butanol mixed solvent; 86 parts of bispheno...

Embodiment 2

[0040] A preparation method of water-based antistatic epoxy floor paint, comprising the following steps:

[0041] S1: Preparation of composite conductive material: (1) Stir and disperse 16 parts of 3-aminopropyltriethoxysilane weighed in absolute ethanol, set the stirring speed to 300rmp, and stir for 40 minutes; add ammonia solution Adjust the pH to 10; add 40 parts of silica nanoparticles, react for 1 hour, centrifugally wash, filter, and dry at 50°C to obtain aminated silica for use; (2) Ultrasonic disperse 8 parts of graphene oxide airgel In deionized water, add aminated silicon dioxide, set the stirring to 500rmp; add ammonia water, set the reaction temperature to 90°C and react for 5 hours, filter and wash, and freeze-dry at -30°C to obtain a composite conductive material for future use.

[0042] S2: Preparation of water-based epoxy curing agent; dissolve 10 parts of triethylenetetramine weighed in 2-butoxyethanol and n-butanol mixed solvent; configure 80 parts of bisphe...

Embodiment 3

[0045] A preparation method of water-based antistatic epoxy floor paint, comprising the following steps:

[0046] S1: Preparation of composite conductive material: (1) Stir and disperse 24 parts of 3-aminopropyltriethoxysilane weighed in absolute ethanol, set the stirring speed to 400rmp, and stir for 60 minutes; add ammonia solution Adjust the pH to 10; add 60 parts of silica nanoparticles, react for 2 hours, centrifugally wash, filter, and dry at 55°C to obtain aminated silica for use; (2) ultrasonically disperse 12 parts of graphene oxide airgel In deionized water, add aminated silicon dioxide, set the stirring to 600rmp; add ammonia water, set the reaction temperature to 95°C and react for 6 hours, filter and wash, and freeze-dry at -50°C to obtain a composite conductive material for later use.

[0047] S2: Preparation of water-based epoxy curing agent; dissolve 15 parts of triethylenetetramine weighed in 2-butoxyethanol and n-butanol mixed solvent; configure 95 parts of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com