Zinc tungstate/zinc oxide heterogeneous nanofiber as well as preparation method and application thereof

A nanofiber, zinc tungstate technology, applied in the field of nanomaterials, can solve the problems of poor selectivity, slow response, poor stability, etc., and achieve the effect of improving gas sensing performance, promoting adsorption and analysis, and high sensitivity response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of zinc tungstate / zinc oxide heterogeneous nanofiber, its preparation method comprises the steps:

[0032] (1) Add 0.5949g (2mmol) of zinc nitrate hexahydrate, 1.5g of polyvinylpyrrolidone and 0.1152g (0.04mmol) of phosphotungstic acid to 9mL of N,N-dimethylformamide, After stirring and mixing at a rate of 500rpm for 12h, a transparent and uniform precursor solution was obtained;

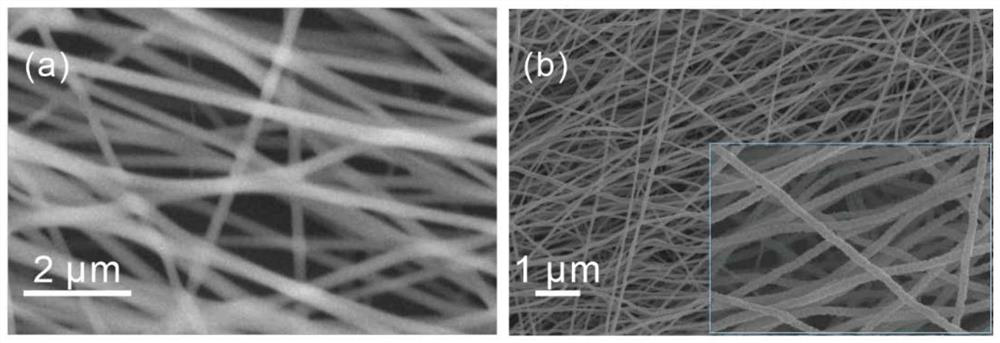

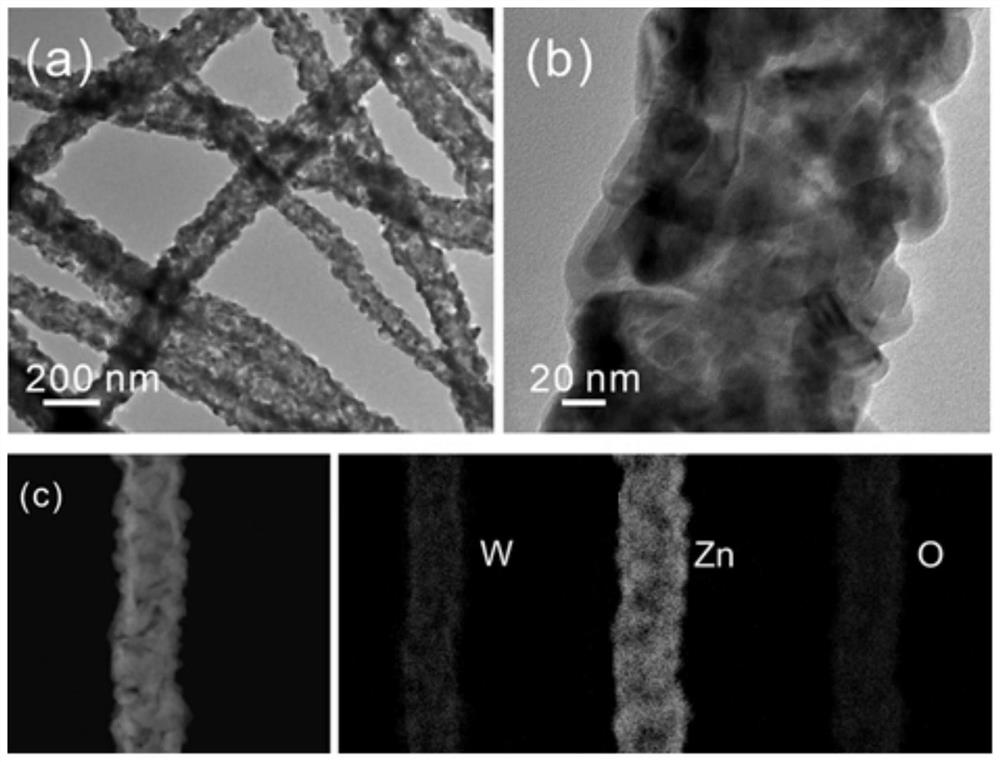

[0033] (2) Put the above precursor solution into a 5mL plastic syringe with a blunt stainless steel needle (the needle specification is 20G) for electrospinning, fix the distance between the needle and the aluminum foil collector substrate to 15cm, and apply 15kV Spinning voltage to obtain precursor nanofibers;

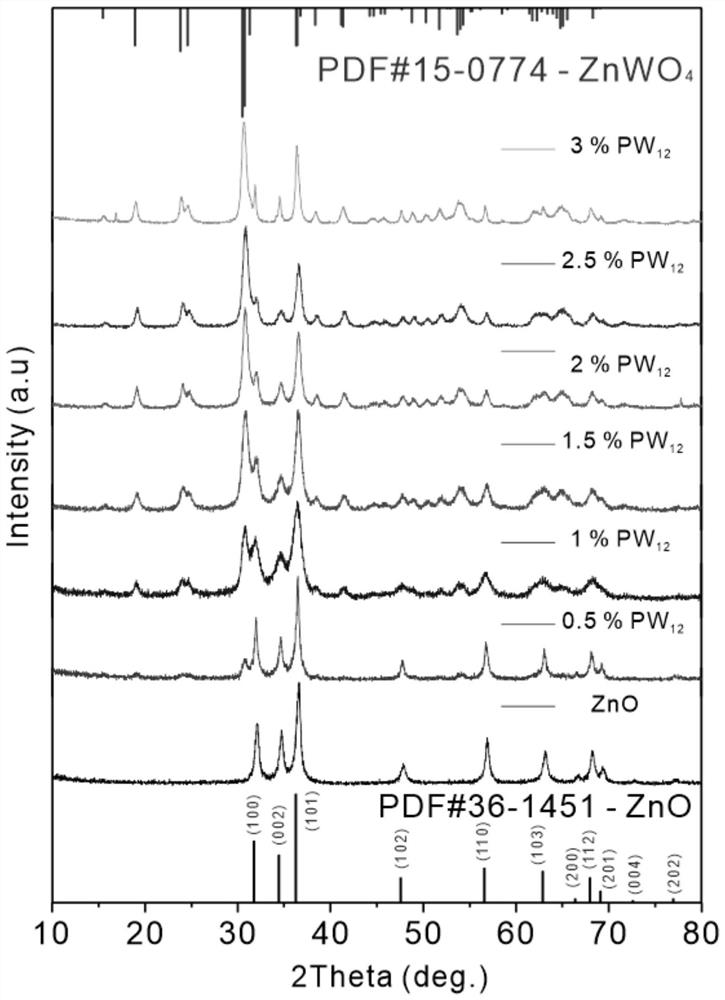

[0034] (3) Calcining the above-mentioned precursor fibers in the air, raising the temperature from room temperature to 600°C at a heating rate of 2°C / min, and calcination for 4 hours at a heat preservation temperature, to obtain the zinc tungstate / zinc oxide heterogeneous nan...

Embodiment 2

[0040] A kind of zinc tungstate / zinc oxide heterogeneous nanofiber, its preparation method comprises the steps:

[0041] (1) Add 0.5949g (2mmol) of zinc nitrate hexahydrate, 1.5g of polyvinylpyrrolidone and 0.0288g (0.01mmol) of phosphotungstic acid to 9mL of N,N-dimethylformamide, After stirring and mixing at a rate of 500rpm for 12h, a transparent and uniform precursor solution was obtained;

[0042] (2) Put the above precursor solution into a 5mL plastic syringe with a blunt stainless steel needle (the needle specification is 20G) for electrospinning, fix the distance between the needle and the aluminum foil collector substrate to 15cm, and apply 15kV Spinning voltage to obtain precursor nanofibers;

[0043] (3) Calcining the above-mentioned precursor fibers in the air, raising the temperature from room temperature to 600°C at a heating rate of 2°C / min, and sintering for 4 hours at a heat preservation temperature to obtain the zinc tungstate / zinc oxide heterogeneous nanofi...

Embodiment 3

[0045] A kind of zinc tungstate / zinc oxide heterogeneous nanofiber, its preparation method comprises the steps:

[0046] (1) Add 0.5949g (2mmol) of zinc nitrate hexahydrate, 1.5g of polyvinylpyrrolidone and 0.0576g (0.02mmol) of phosphotungstic acid to 9mL of N,N-dimethylformamide, After stirring and mixing at a rate of 500rpm for 12h, a transparent and uniform precursor solution was obtained;

[0047] (2) Put the above precursor solution into a 5mL plastic syringe with a blunt stainless steel needle (the needle specification is 20G) for electrospinning, fix the distance between the needle and the aluminum foil collector substrate to 15cm, and apply 15kV Spinning voltage to obtain precursor nanofibers;

[0048] (3) Calcining the above-mentioned precursor fibers in the air, raising the temperature from room temperature to 600°C at a rate of 2°C / min, and calcination at a heat preservation rate of 4h to obtain the zinc tungstate / zinc oxide heterogeneous nanofibers. %PW 12 expr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com