A preparation method of a gas-sensing test element based on lanthanum molybdate nanomaterials

A technology for testing components and nanomaterials, which is applied in the fields of nanotechnology, nanotechnology, and analytical materials for materials and surface science. It can solve the problems of complex synthesis process, short service life and high use temperature, and achieve high chemical activity. , Simple operation, rapid reaction and heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

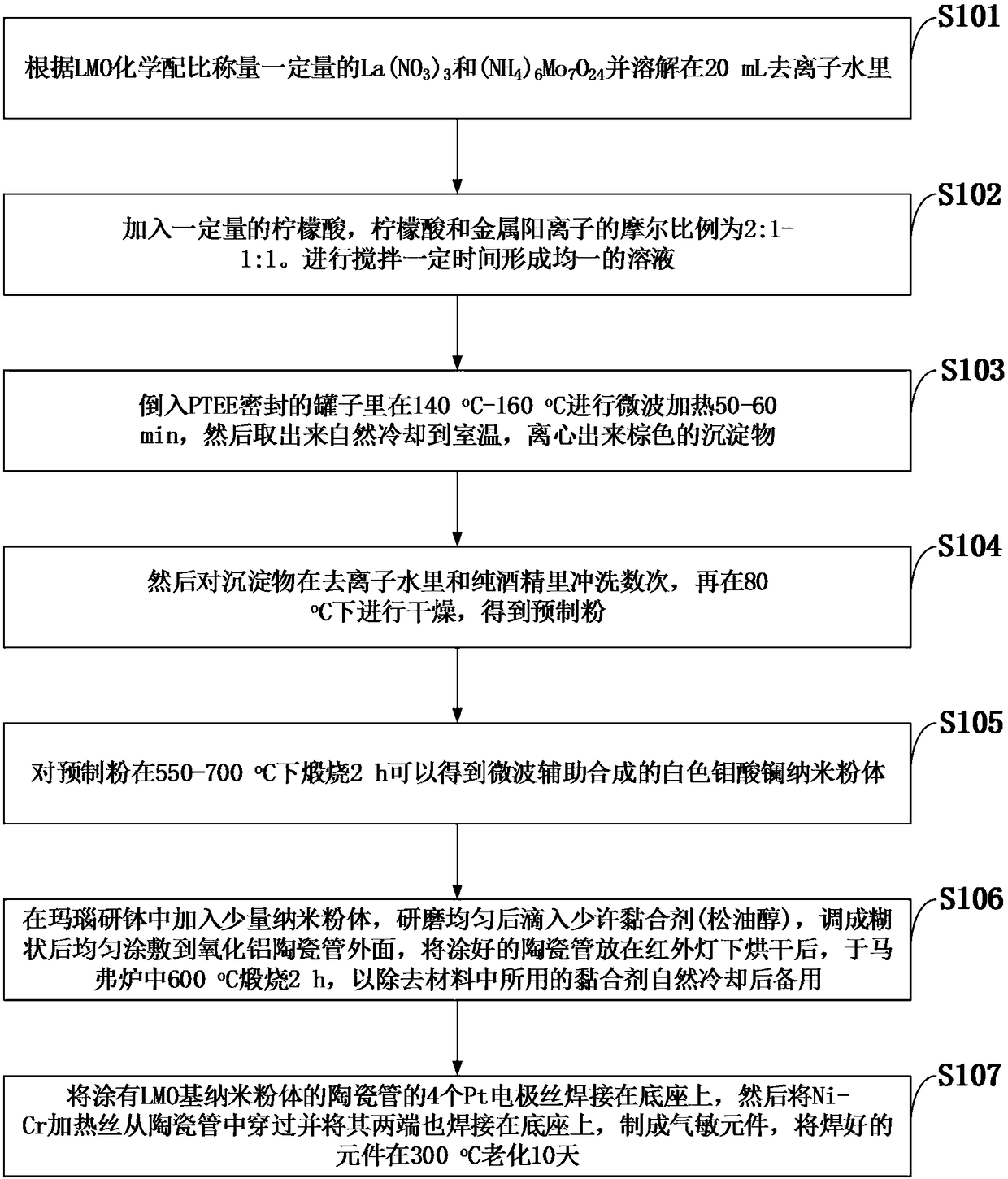

[0053] Such as figure 1 As shown, the preparation method of the gas-sensing test element based on the lanthanum molybdate nanomaterial of the embodiment of the present invention comprises the following steps:

[0054] S101: Weigh a certain amount of La(NO 3 ) 3 and (NH 4 ) 6 Mo 7 o 24 And dissolved in 20mL deionized water;

[0055] S102: Add a certain amount of citric acid, the molar ratio of citric acid and cation is 2:1-1:1. Stir for a certain period of time to form a homogeneous solution;

[0056] S103: Pour it into a sealed PTFE jar and heat it in microwave at 140°C-160°C for 50-60min, then take it out and let it cool down to room temperature naturally, and centrifuge to get the brown precipitate;

[0057] S104: Rinse the precipitate several times in deionized water and pure alcohol, and then dry it at 80°C to obtain prefabricated powder;

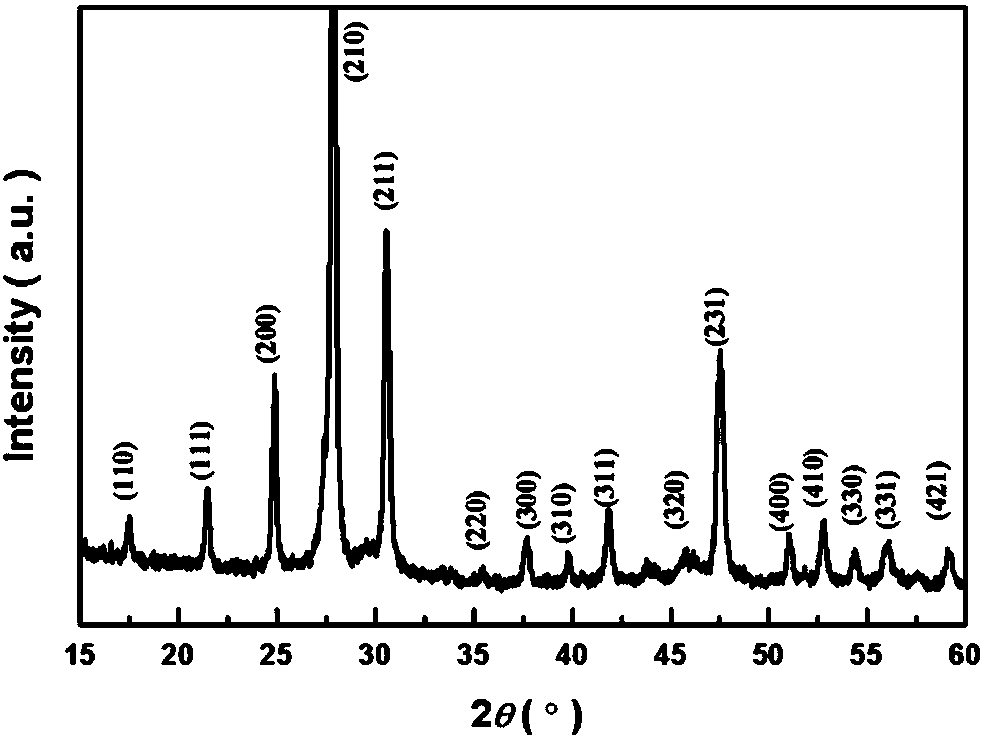

[0058] S105: Calcining the prefabricated powder at 550-700°C for 2 hours to obtain white lanthanum molybdate nanopowders synt...

Embodiment 1

[0062] Embodiment 1, according to LMO stoichiometric ratio weighs the corresponding amount of La (NO 3 ) 3 and (NH 4 ) 6 Mo 7 o 24 And dissolved in 20mL deionized water. Add a certain amount of citric acid, the molar ratio of citric acid and metal cation is 2:1. Stir for a certain period of time to form a homogeneous solution; pour it into a PTEE sealed jar and heat it with microwaves at 160°C for 50 minutes, then take it out and cool it to room temperature naturally, and centrifuge the brown precipitate; then mix the precipitate in deionized water with pure Rinse several times in alcohol, then dry at 80°C to obtain prefabricated powder; calcinate the prefabricated powder at 700°C for 2 hours to obtain white lanthanum molybdate nanopowder synthesized by microwave; add a small amount of nanopowder in agate mortar After grinding evenly, drop a little binder (terpineol) into a paste and apply it evenly on the surface of the alumina ceramic tube. After drying the coated cera...

Embodiment 2

[0063] Embodiment 2, according to LMO stoichiometric ratio weighs the corresponding amount of La (NO 3 ) 3 and (NH 4 ) 6 Mo 7 o 24 And dissolved in 20mL deionized water. Add a certain amount of citric acid, the molar ratio of citric acid and metal cation is 1.5:1. Stir for a certain period of time to form a homogeneous solution; pour it into a PTEE sealed jar and heat it with microwaves at 160°C for 50 minutes, then take it out and cool it to room temperature naturally, and centrifuge the brown precipitate; then mix the precipitate in deionized water with pure Rinse several times in alcohol, then dry at 80°C to obtain prefabricated powder; calcinate the prefabricated powder at 700°C for 2 hours to obtain white lanthanum molybdate nanopowder synthesized by microwave; add a small amount of nanopowder in agate mortar After grinding evenly, add a little terpineol, adjust it into a paste and apply it evenly on the surface of the alumina ceramic tube, dry the coated ceramic tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com