High-energy electron beam irradiation processing method of self-shielding radiation source

A technology of high-energy electron beam and processing method, applied in the field of electron beam irradiation processing, can solve the problems of environmental pollution, high energy consumption, high emission and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

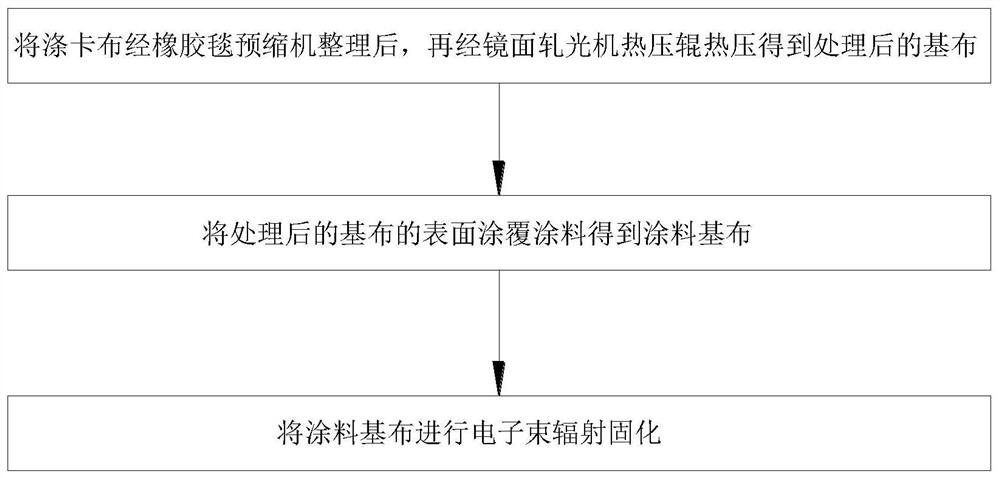

[0029] Please refer to figure 1 shown. The embodiment of the present application provides a self-shielding radiation source high-energy electron beam irradiation processing method, which includes the following steps: after finishing the polyester card cloth with a rubber blanket pre-shrinking machine, and then heat-pressing it with a mirror calender hot-pressing roller to obtain The treated base cloth; the surface of the treated base cloth is coated with a paint to obtain a paint base cloth; the paint base cloth is cured by electron beam radiation.

[0030] In the above-mentioned embodiment, first, the polyester card cloth with a relative humidity of 10%-15% is pre-shrunk and finished by a rubber blanket pre-shrinker, and then hot-pressed by a mirror calender hot-pressing roller to obtain a treated base cloth, and then The treated base cloth is coated with paint, wherein the mass ratio of paint is vinyl silicone oil 60%-75%, dimethyl silicone oil 15%-20%, hydrogen-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com