System and method for monitoring acidity of oxidation liquid in device for producing hydrogen peroxide by anthraquinone method

A hydrogen peroxide and monitoring system technology is applied in the field of monitoring systems for the acidity of an oxidizing liquid in a device for producing hydrogen peroxide by an anthraquinone method, and can solve the problems of inability to realize on-line monitoring, affecting the safety of the device, and high operational risk, and achieving The effect of avoiding residual influence, simple structure, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

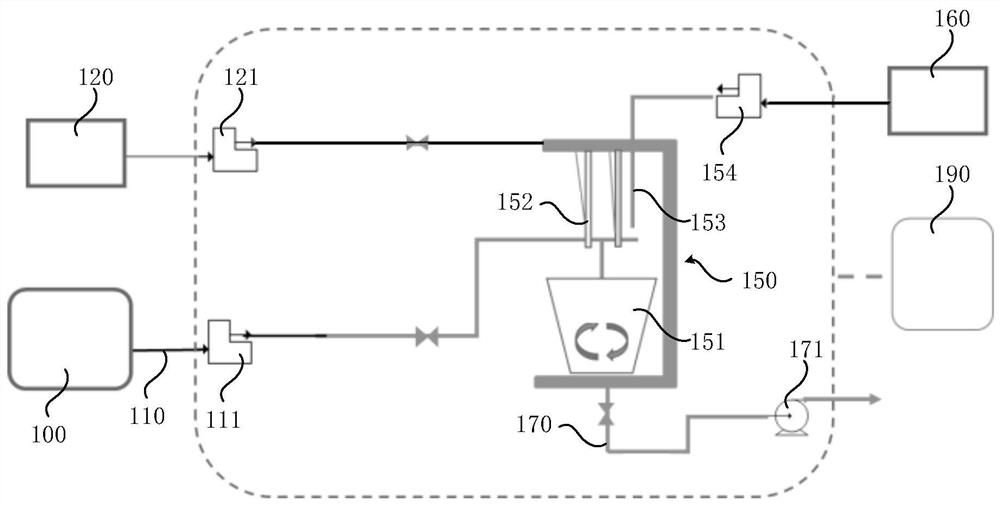

[0074] refer to figure 1 As shown, the monitoring system of this embodiment is used to monitor the acidity of the oxidizing solution in the device for producing hydrogen peroxide by anthraquinone method.

[0075]In this embodiment, 2ml of oxidizing solution and 20ml of pure water are injected into the analysis pool 151 for each detection. After the sample injection is completed, the analysis cell 151 continues to stir for 30 seconds, and stands still for 30 seconds to separate layers. The acidity value of the separated aqueous phase solution in the analysis cell 151 is detected by the detection component. Rinse 8 three times after each test. In this embodiment, continuous detection is set, that is, the next detection process is automatically started after one detection process is completed.

[0076] When this embodiment runs for 800 hours, more than 9,000 detections are completed, realizing long-period, high-frequency online monitoring and improving the safety of the device...

Embodiment 2

[0078] refer to figure 1 As shown, the monitoring system of this embodiment is used to monitor the acidity of the oxidizing solution in the device for producing hydrogen peroxide by anthraquinone method.

[0079] In this embodiment, 3ml of oxidizing solution and 15ml of pure water are injected into the analysis pool 151 for each detection. After the sample injection is completed, the analysis cell 151 continues to stir for 20 seconds, and stands still for 20 seconds to separate layers. The acidity value of the separated aqueous phase solution in the analysis cell 151 is detected by the detection component. After each test, rinse three times. In this embodiment, it is set to perform detection every 1 hour.

[0080] The monitoring system of this embodiment realizes the on-line monitoring of the acidity of the oxidizing solution in the device for producing hydrogen peroxide by anthraquinone method, and improves the safety of the device.

Embodiment 3

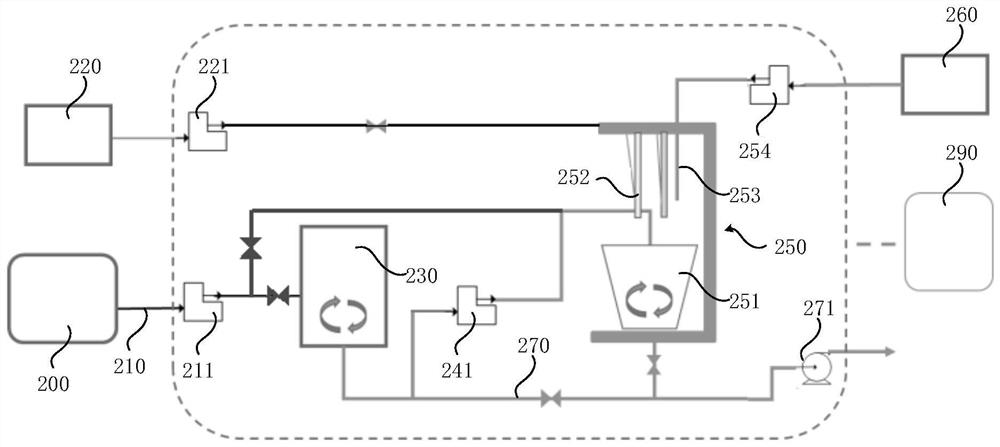

[0082] refer to figure 2 As shown, the monitoring system of this embodiment is used to monitor the acidity of the oxidizing solution in the device for producing hydrogen peroxide by anthraquinone method.

[0083] In this embodiment, 100ml of oxidizing solution is drawn into the buffer pool 230 for each sampling, and 20ml of oxidizing solution is extracted from the buffer pool 230 and 20ml of pure water is injected into the analysis pool 251 for each detection. After the sample injection is completed, the analysis cell 251 continues to stir for 25 seconds, and stands still to separate layers for 25 seconds. The detection unit 250 of this embodiment adopts potentiometric titration detection. Rinse the analytical cell three times after each test. Three parallel detections were performed for each sampling. In this embodiment, continuous detection is set, that is, the next sampling and detection process is automatically started after three detection processes of one sampling ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com