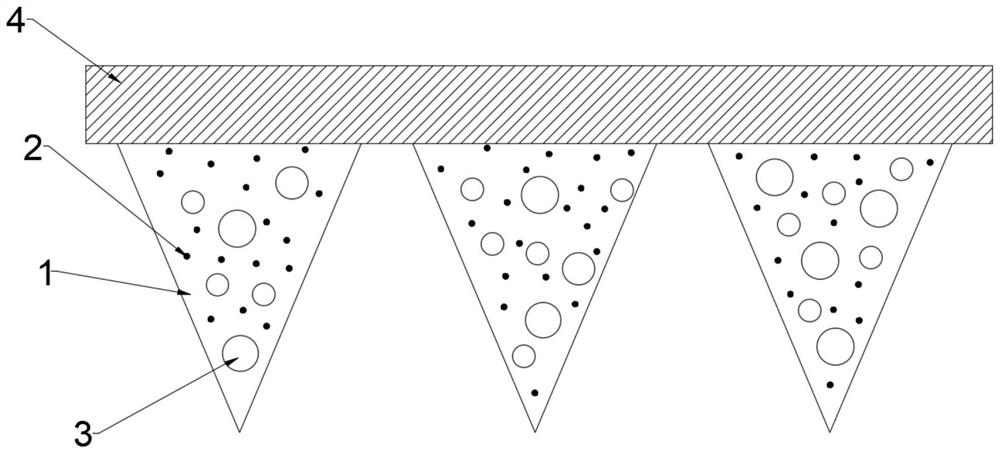

Soluble microneedle patch as well as preparation method and application thereof

A microneedle patch and soluble technology, applied in the direction of biochemical equipment and methods, microneedles, needles, etc., can solve the problems of poor long-term treatment effect, low drug delivery efficiency, and poor convenience, so as to inhibit sweat glands from secreting sweat and realize Long-term treatment, the effect of improving high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the dissolvable microneedle patch described in this embodiment comprises the following steps:

[0030] (1) Blend the functional ingredient botulinum toxin A with the microsphere solution, add it into the water phase and stir at a high speed, and the stirring rate is 450r / min; wherein the water phase adopts deionized water; the microsphere solution is polyethylene A mixed solution prepared from alcohol and a solvent, the concentration of polyvinyl alcohol in the mixed solution is 50g / L, and the solvent is dioxane; after stirring, the slow-release microspheres composed of polyvinyl alcohol and functional ingredients are in the water phase A precipitate formed. The molecular weight of the botulinum toxin A described in this example ranges from 150 to 900 kDa.

[0031] (2) The slow-release microspheres generated in step (1) are precipitated and separated by filtration or centrifugation, and after the slow-release microspheres and magnesium particl...

Embodiment 2

[0038] The preparation method of the dissolvable microneedle patch described in this embodiment comprises the following steps: (1) blending the functional ingredient botulinum toxin A with the microsphere solution, and then adding it into the water phase for high-speed stirring, the stirring rate It is 850r / min; wherein the water phase adopts ultrapure water; the microsphere solution is a mixed solution prepared from polyethylene glycol and a solvent, and the concentration of polyethylene glycol in the mixed solution is 100g / L, and the solvent It is a toluene solvent; after stirring, the slow-release microspheres composed of polyethylene glycol and functional ingredients form a precipitate in the water phase. The molecular weight of the botulinum toxin A described in this example ranges from 150 to 900 kDa.

[0039] (2) The slow-release microspheres generated in step (1) are precipitated and separated by filtration or centrifugation, and after the slow-release microspheres and...

Embodiment 3

[0046] The preparation method of the dissolvable microneedle patch described in this embodiment comprises the following steps:

[0047] (1) The functional component botulinum toxin A is blended with the microsphere solution, and then added to the water phase for high-speed stirring, and the stirring rate is 550r / min; wherein the water phase adopts deionized water; the microsphere solution is A mixed solution prepared from polylactic acid and a solvent, the concentration of polylactic acid in the mixed solution is 400g / L, and the solvent is methanol; after stirring, the slow-release microspheres composed of polylactic acid and functional ingredients are formed in the water phase precipitation. The molecular weight of the botulinum toxin A described in this example ranges from 150 to 900 kDa.

[0048] (2) The slow-release microspheres generated in step (1) are precipitated and separated by filtration or centrifugation, and after the slow-release microspheres and magnesium parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com