Injection molding machine

A technology for injection molding machines and injection molding tubes, applied in the field of injection molding machines, can solve problems such as low work efficiency, bubbles, and unqualified products, and achieve the effects of improving pass rate, drying efficiency, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

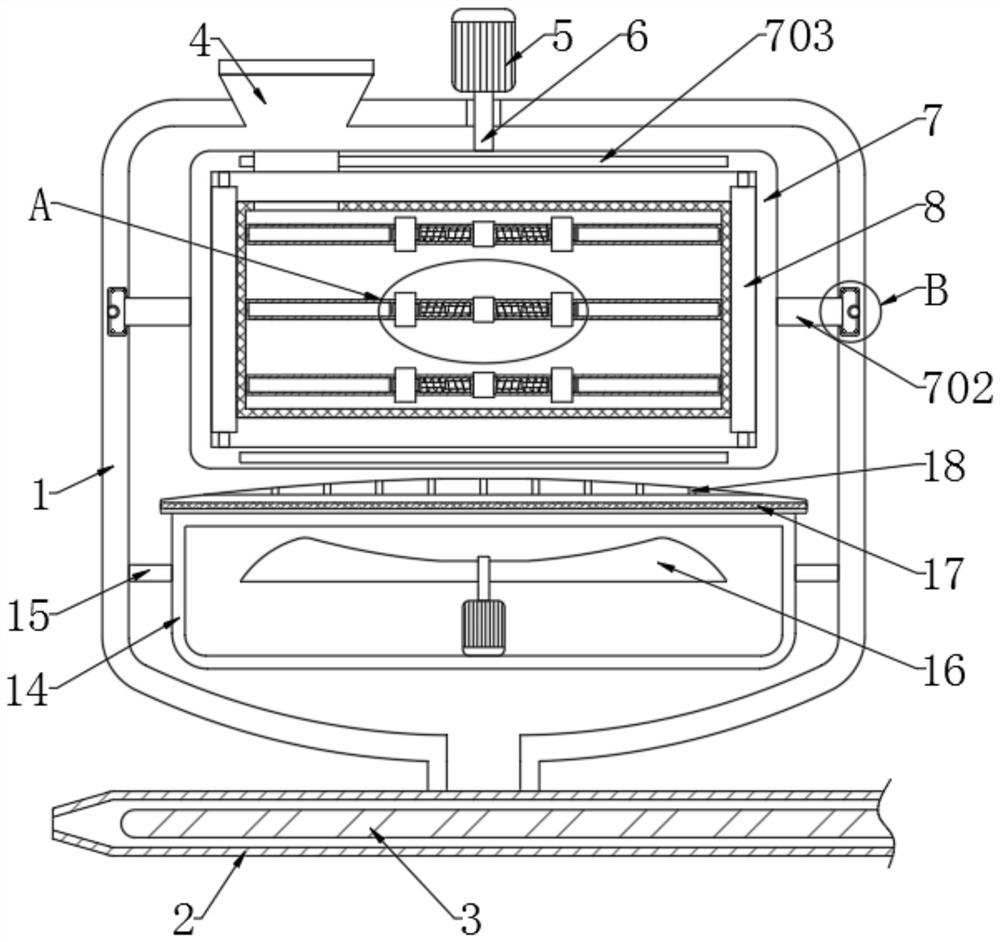

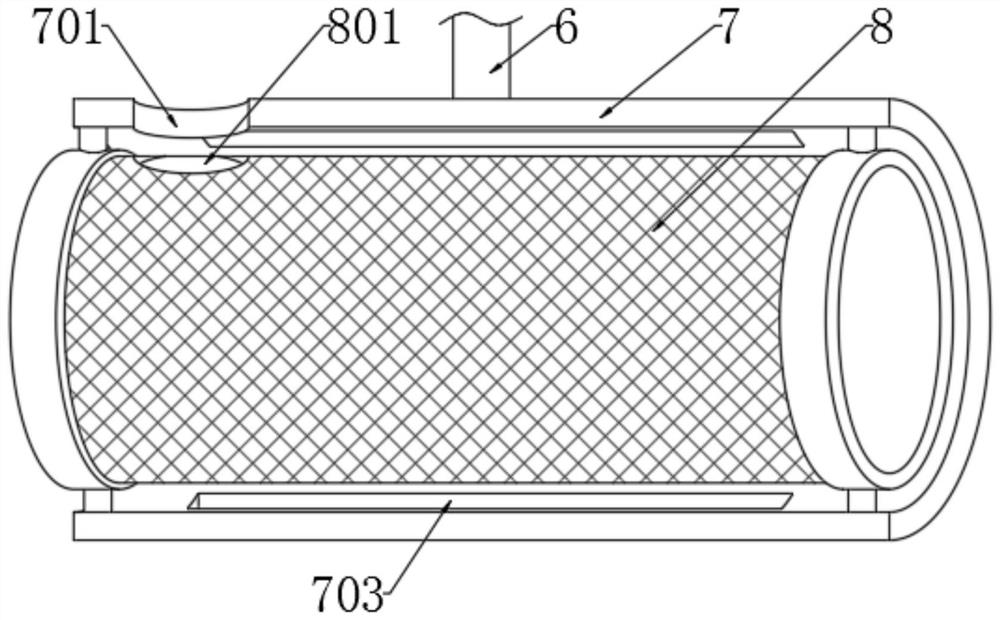

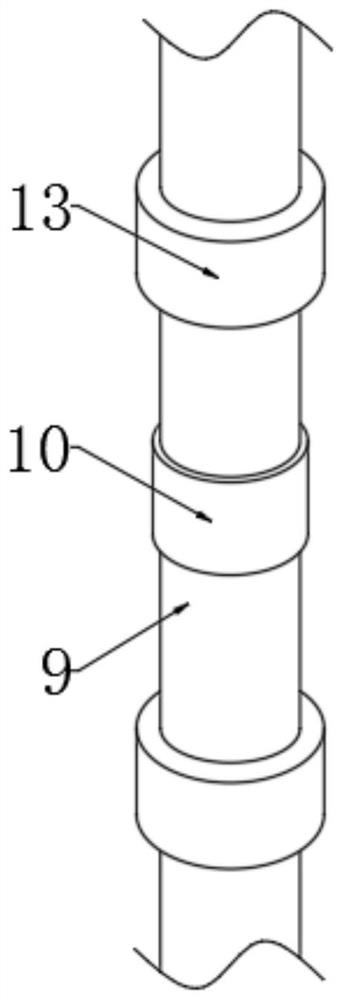

[0035] see Figure 1-5 , an injection molding machine, comprising a drying box 1, an injection molding pipe 2 and a threaded pipe 3, the lower end of the drying box 1 is connected with an injection molding pipe 2, the inside of the injection molding pipe 2 is provided with a threaded pipe 3, and the upper end of the drying box 1 is provided with There is a feeding funnel 4, the upper end of the feeding funnel 4 is provided with a cover plate, the cover plate needs to be closed during the injection molding work, the upper end of the drying box 1 is drilled with a round hole, and the upper end of the drying box 1 is equipped with a speed regulating motor 5. The outside of the speed-regulating motor 5 is controlled by a frequency converter and PLC. The power output end of the speed-regulating motor 5 is fixedly connected to a rotating shaft 6, and the rotating shaft 6 is set through a round hole and extends to the inner end of the drying box 1. The rotating shaft 6 The lower end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap