Layered wave-absorbing material and preparation method thereof

A wave-absorbing material and layered technology, which is applied in the field of layered wave-absorbing materials and their preparation, can solve the problems affecting the wave-absorbing performance of materials, the difficulty of precise control of shape and structure, and the difficulty of precise control of structure, so as to achieve reliable quality, Improved impedance matching performance and electromagnetic wave attenuation performance, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a layered wave-absorbing material, the layered wave-absorbing material comprising a base layer, a lossy layer formed on the base layer, and a polymer carbonized layer formed on the lossy layer; the preparation method Include the following steps:

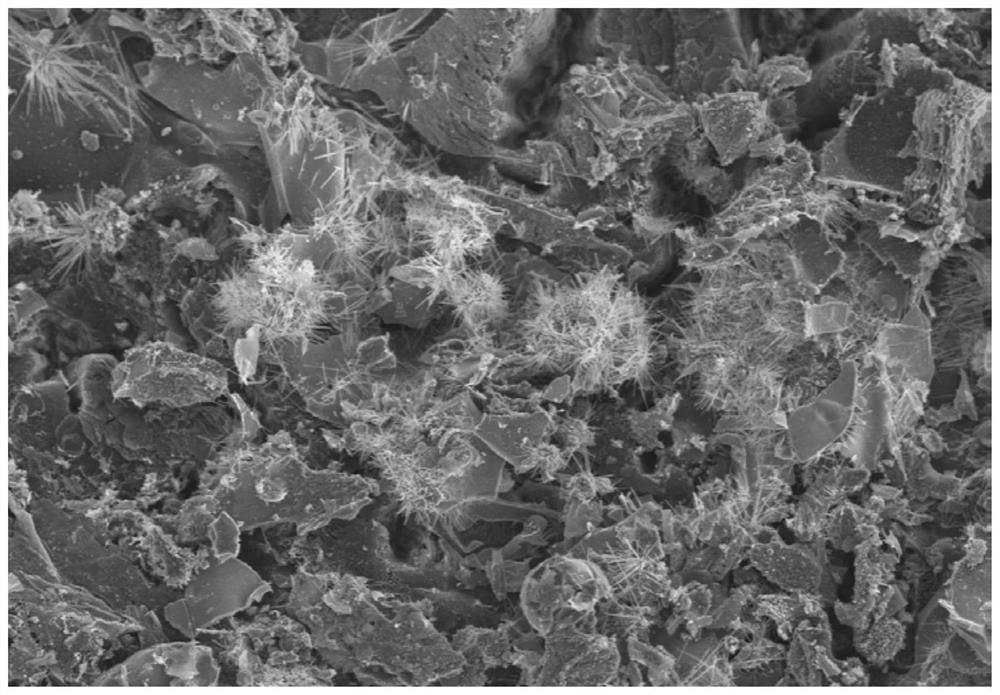

[0018] (1) Laser carbonizing the polymer film to form carbides to form the base layer, and coating the base layer with a mixture solution of metal salts;

[0019] (2) laser treating the mixture solution of the metal salt to form the lossy layer, and coating a polymer solution on the lossy layer;

[0020] (3) laser processing the high molecular polymer solution to form the high molecular carbonized layer;

[0021] (4) If the lossy layer is greater than 1 layer and the polymerized carbonized layer is greater than 1 layer, repeat steps (2) and (3) to form the lossy layer and the polymerized carbonized layer on the base layer an overlay of alternating layers;

[0022] (5) Annealing the material obtained a...

Embodiment 1

[0036] The preparation method of layered wave-absorbing material comprises the following steps:

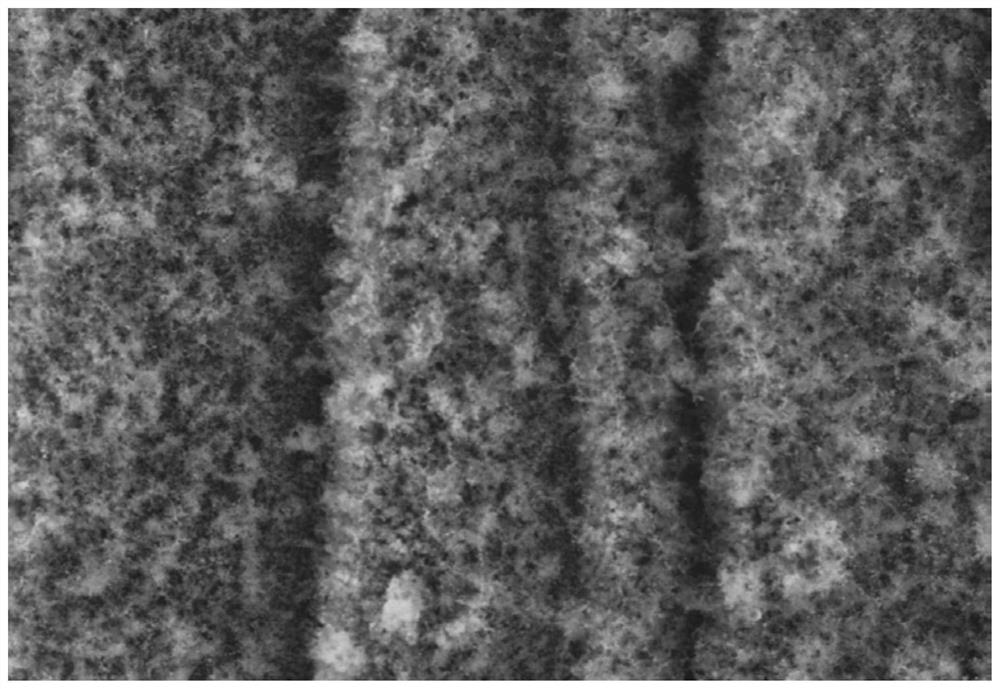

[0037] 1. Making the base layer: The polymer film used to make the base layer is a PI film with a thickness of 50 μm. Before use, it is washed repeatedly with deionized water and ethanol for 3-5 times, and then dried at a constant temperature of 60°C for 30 minutes. Then move the cleaned and dried PI film into a square hollow container that can provide an inert gas atmosphere for laser processing, wherein the inert gas inlet and outlet rates of the inert gas inlet and outlet on both sides of the hollow container The inert gas here is nitrogen at 10ml / min. The PI film can be processed by a pulsed laser with a high repetition rate. It can be processed once or twice with the same or different processing accuracy. In this example, the first rough processing and the second fine processing are used. Secondary processing technology to precisely control the micro-nano porous structure. ...

Embodiment 2

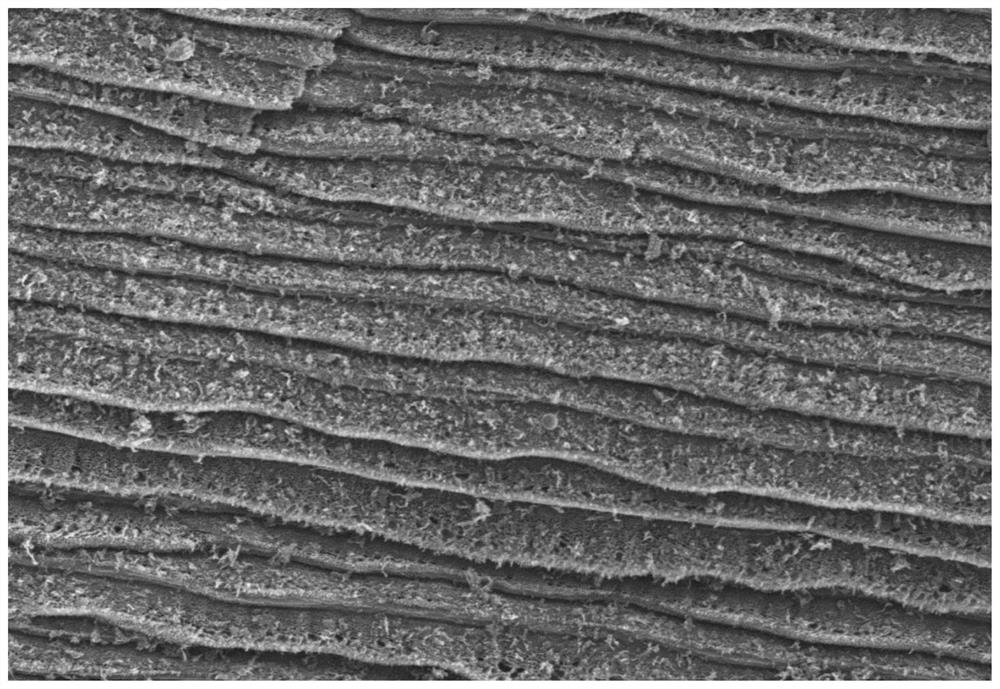

[0044] The difference from Example 1 is that the laser processing parameters in step 1 are different. In this embodiment, the PI film is processed by one laser processing, and the parameters are set as follows: laser power is 4w, repetition frequency is 800KHz, and defocus is 10μm , The scanning speed is 50mm / s, and the scanning distance is 10μm. The SEM figure of the base layer that this embodiment obtains is as Figure 6 shown.

[0045] The thickness and absorbing performance of the layered absorbing material prepared by the present invention can be determined by the type of laser, the working parameter setting of the laser, the type of polymer film, the mixture solution of metal salt, the polymer solution, and the temperature and time of annealing, etc. parameter adjustment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com