Core-shell toughening agent, preparation method thereof and toughened nylon applying core-shell toughening agent

A core-shell toughening agent and a technology of a toughening agent, applied in the field of toughening nylon, can solve the problems of unstable toughening effect of the toughening agent, affecting the quality of nylon, increasing processing difficulty, etc., and achieving excellent toughening effect and physical properties. Improve the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

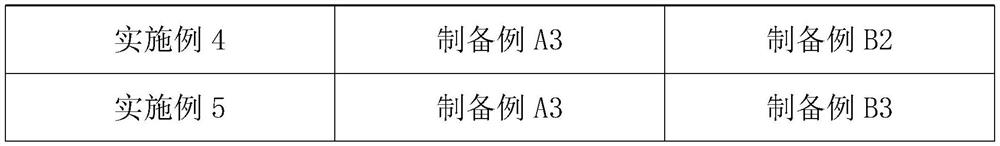

[0041] Preparation example of polyketone graft and EPDM graft

[0042] Preparation example of polyketone graft

preparation example A1

[0044] In this preparation example, 2,5-di-tert-butylperoxy-2,5-dimethylhexane (DHBP) was selected as the first initiator.

[0045] 0.5kgDHBP and 5kg maleic anhydride were uniformly mixed in a mixing device to form a mixture, and the mixing time was 10 minutes. Add 94kg of polyketone to the twin-screw extruder after metering the main feed, and add the mixture of DHBP and maleic anhydride to the twin-screw extruder after metering the side feed, melt and plasticize, react extrusion, granulate, cool, Dry to obtain polyketone grafts.

[0046] The screw speed is 450r / min, and the screw length-to-diameter ratio is 52:1.

[0047] During the reaction, set the temperature of each section inside the twin-screw extruder as follows: first section 155°C, second section 195°C, third section 215°C, fourth section 215°C, fifth section 215°C, sixth section 205°C, seventh section 205°C ℃, eighth section 195°C, ninth section 185°C, tenth section 185°C, nose section 235°C.

preparation example A2

[0049] In this preparation example, bis-tert-butylperoxydiisopropylbenzene (BIPB) was selected as the first initiator.

[0050] 0.25kg BIPB and 3kg maleic anhydride were uniformly mixed in a mixing device to form a mixture, and the mixing time was 10 minutes. Add 96kg of polyketone to the twin-screw extruder after metering the main feed, and add the mixture of BIPB and maleic anhydride to the twin-screw extruder after metering the side feed, melt plasticization, reaction extrusion, granulation, cooling, Dry to obtain polyketone grafts.

[0051] The screw speed is 400r / min, and the screw length-to-diameter ratio is 52:1.

[0052] During the reaction, set the temperature of each section inside the twin-screw extruder as follows: first section 165°C, second section 205°C, third section 225°C, fourth section 225°C, fifth section 225°C, sixth section 215°C, seventh section 215°C ℃, eighth section 205°C, ninth section 195°C, tenth section 195°C, nose section 235°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com