Low-molecular-weight polybutadiene emulsion and release agent

A technology of polybutadiene and low molecular weight, which is applied in the direction of conjugated diene coating, casting mold composition, coating, etc., and can solve the problems of low toughness and impact resistance, low surface energy, and insufficient density of film formation. Achieve strong impact resistance, improved strength and toughness, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of low molecular weight polybutadiene emulsion

[0033] 1) Raw materials:

[0034] (1) Low molecular weight polyteadiene, commercially available.

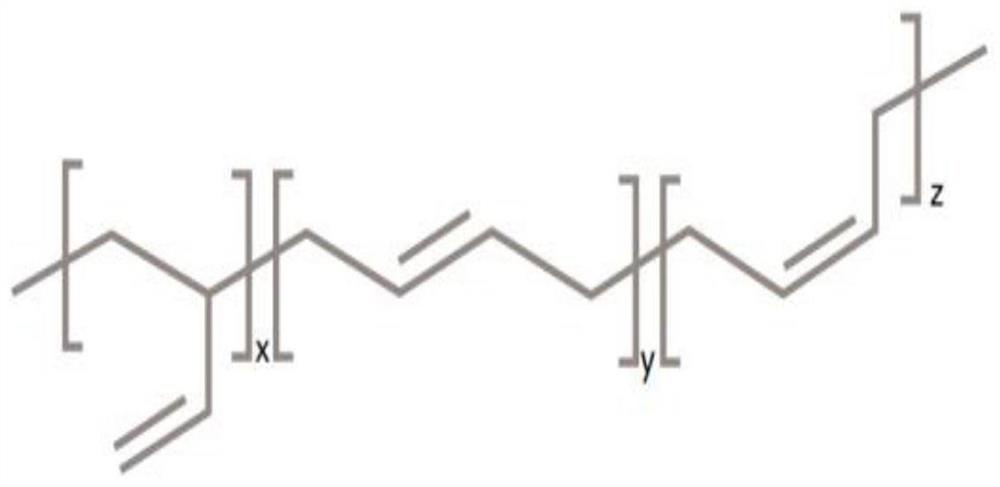

[0035] The low molecular weight polybutadiene comprises: 1, 2 vinyl double bond (1%); 1, 4 cis double bond (82%); 1, 4 trans 2 bond (17%); Mn = 2900 .

[0036] (2) Carbon (10) isomeric alcohol polyoxyethylene ether (EO = 10), commercially available.

[0037] (3) Polymer emulsified dispersant, EO / PO block copolymer, commercially available.

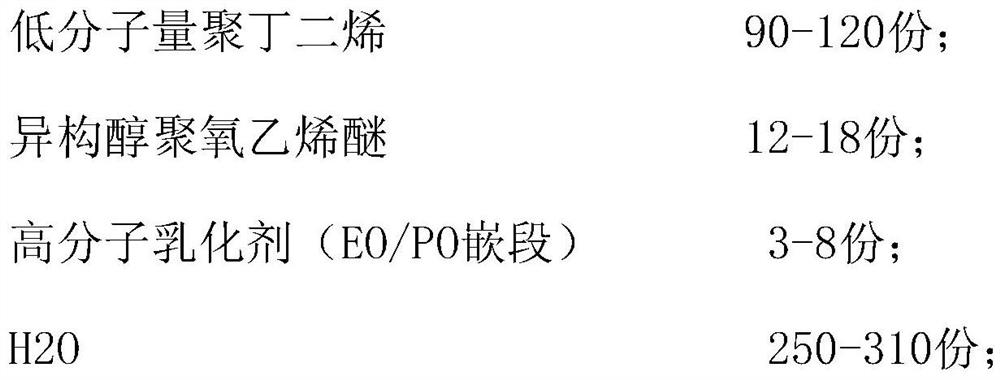

[0038] 2) The ratio of the above raw materials is (calculated by weight fraction):

[0039]

[0040] 3) Polymerization process

[0041] The raw material was mixed, warmed to 90 ° C, add 1 / 3 (90 ° C) hot water, stirred at a high speed mixer for 30 min, increase the rotational speed to 12000 rpm, and slowly add 2 / 3 normal temperature water. Hold 40 ° C for 30 min, filtered, and the light white emulsion of 0.2 μm particle size was obtained.

Embodiment 2

[0042] Example 2. Preparation of low molecular weight polybutadiene emulsion

[0043] 1) Raw materials:

[0044] (1) Low molecular weight polyteadiene, commercially available.

[0045] The low molecular weight polybutadiene properties include a 1,2 vinyl double bond (61%); 1, 4 cis double bond (39%); Mn = 2200.

[0046] (2) Carbon (13) isomeric alcohol polyoxyethylene ether (EO = 7), commercially available.

[0047] (3) Polymer emulsified dispersant, EO / PO block copolymer, commercially available.

[0048] 2) The ratio of the above raw materials is (calculated by weight fraction):

[0049]

[0050] 3) Polymerization process

[0051] The raw material was mixed, warmed to 80 ° C, add 80 parts (80 ° C) hot water, stirred at a high speed mixer 6000 rpm for 30 min, increase the speed to 15000 rpm, and gradually add 200 normal warm water. The mixture was stirred at 40 ° C for 30 min, and the discharge was filtered to give a light white emulsion having a particle size of 0.2 μm.

[00...

Embodiment 3

[0053] Example 3: Molecularly polybutadiene emulsion produced using Example 1 Making PU Solentian

[0054] 1) Formulation (by weight of the weight):

[0055]

[0056]

[0057] 2) Application method

[0058] Before using the water, it is doubled, and it is equipped with a working fluid, spray it 4 times. Sole products are not needled to be painted and bonded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com