Near-infrared fluorescent material and preparation method thereof, and LED luminescent device and preparation method thereof

A technology of fluorescent materials and light-emitting devices, which is applied in the field of near-infrared fluorescent materials and preparation, can solve the problems of not being able to meet the needs of photobiological activity, and achieve the effects of meeting the needs of photobiological activity, enhancing capture, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for preparing a near-infrared fluorescent material, comprising the following steps:

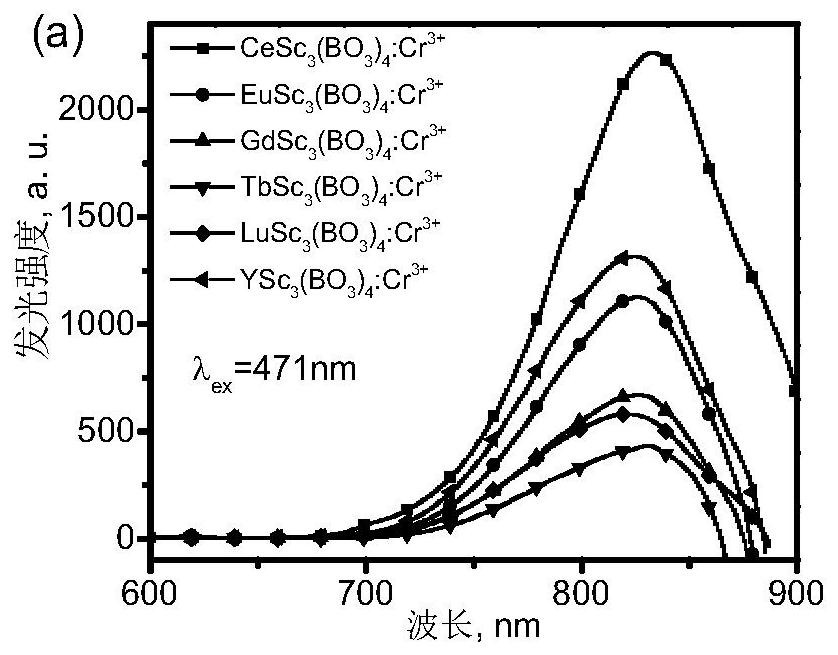

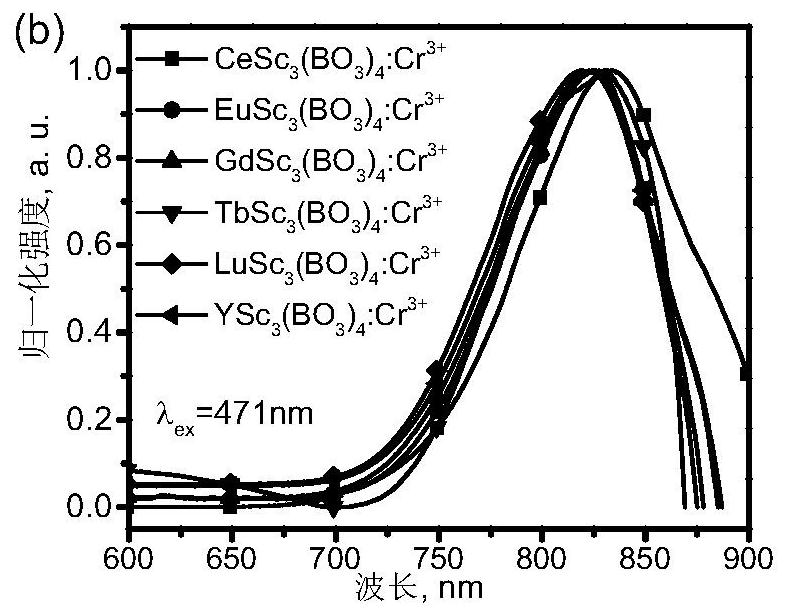

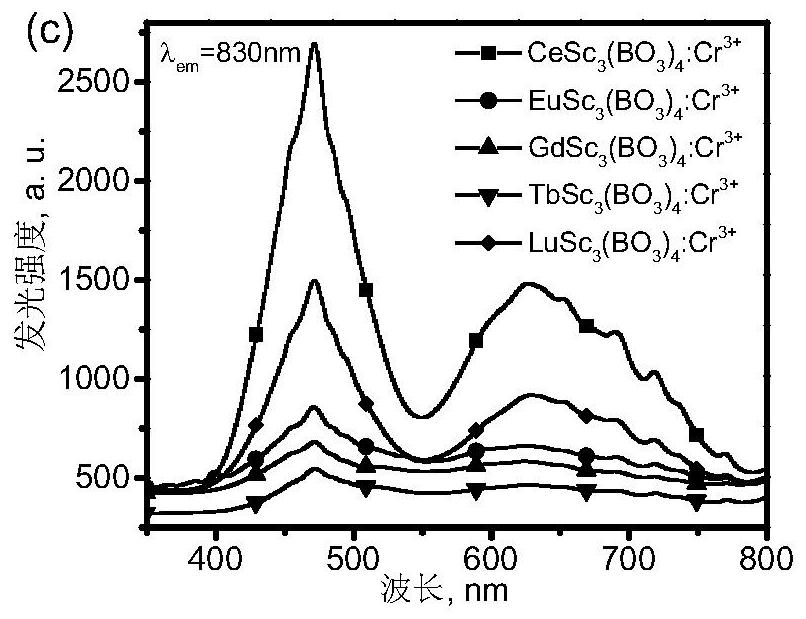

[0056] S1: the oxide of the rare earth element, Sc 2 o 3 、H 3 BO 3 and Cr(NO 3 ) 3 9H2 Oaccording to metering ratio RESc 2.925 Cr 0.075 (BO 3 ) 4 (RE=Ce, Eu, Gd, Lu, Y, Tb) mixed evenly (total weight is 10 grams, H 3 BO 3 5% excess) into a corundum crucible, put the corundum crucible into a muffle furnace, raise the temperature to 200°C at 5°C / min, keep it warm for 0.5h, then raise the temperature to 500°C at 5°C / min, keep it warm for 2h, and then The furnace is cooled to room temperature to obtain the first calcined product; the oxide of the rare earth element is CeO 2 、Eu 2 o 3 、Gd 2 o 3 、Lu 2 o 3 , Y 2 o 3 and Tb 4 o 7 .

[0057] S2: mix the first calcined product with 2% AlF 3 Mix the flux evenly and put it into the corundum crucible, put the corundum crucible into the muffle furnace, raise the temperature to 900°C at 5°C / min...

Embodiment 2-4

[0064] Present embodiment 2-4 provides a kind of preparation method of near-infrared fluorescent material, present embodiment 2-4

[0065] The difference from Example 1 is that the temperature of the second temperature increase in step S2 is different, which are 1150°C, 1200°C and 1300°C respectively;

[0066] Namely S2: mix the first calcined product with 2% AlF 3 Mix the flux evenly and put it into the corundum crucible, put the corundum crucible into the muffle furnace, raise the temperature to 900°C at 5°C / min, keep it for 2h, then raise the temperature to 1150°C at 5°C / min, hold it for 8h, and then keep it at 5°C / min °C / min to cool down to 600 °C, and cool down to room temperature with the furnace to obtain the second calcined product;

[0067] or S2: mix the first calcined product with 2% AlF 3 Mix the flux evenly and put it into the corundum crucible, put the corundum crucible into the muffle furnace, raise the temperature to 900°C at 5°C / min, keep it for 2h, then rai...

Embodiment 5-8

[0072] Present embodiment 5-8 provides a kind of preparation method of near-infrared fluorescent material, present embodiment 5-8

[0073] The difference with embodiment 1 is: the heat preservation time of the second temperature rise of step S2 is different, changed from 8h to 2h, 4h, 6h, 10h respectively;

[0074] Others are the same as in Example 1.

[0075] It can be known from Fig. 2(c)-(d) that the best holding time for preparing near-infrared fluorescent material in the present invention is 8h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com