Method for producing titanium microalloyed Q355B hot-rolled strip steel under non-refining condition

A technology of micro-alloying and hot-rolling strip steel, applied in metal rolling, manufacturing converters, improving process efficiency, etc., can solve the problems of large addition amount, unstable yield of titanium alloy elements, etc., to reduce sulfuration material level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

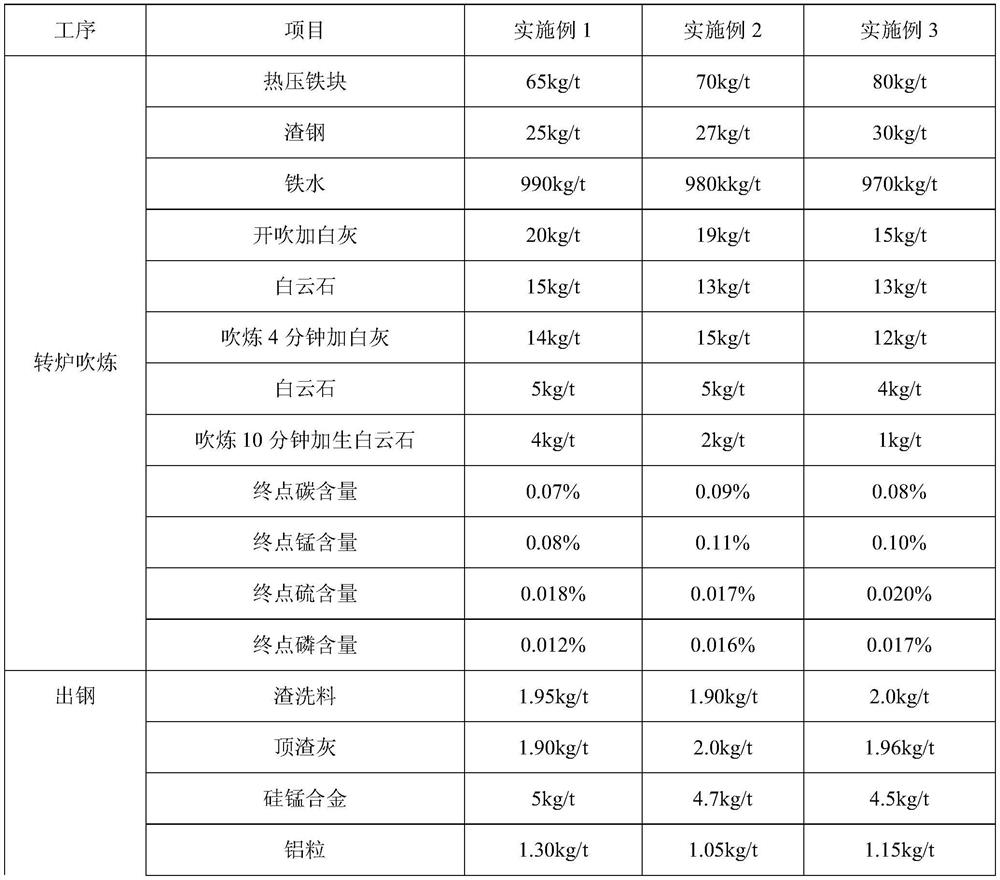

[0026] In the following examples, the converter is 120t, the steel type is Q355 series, the billet is 165*505, and the hot rolling mill is 850mm.

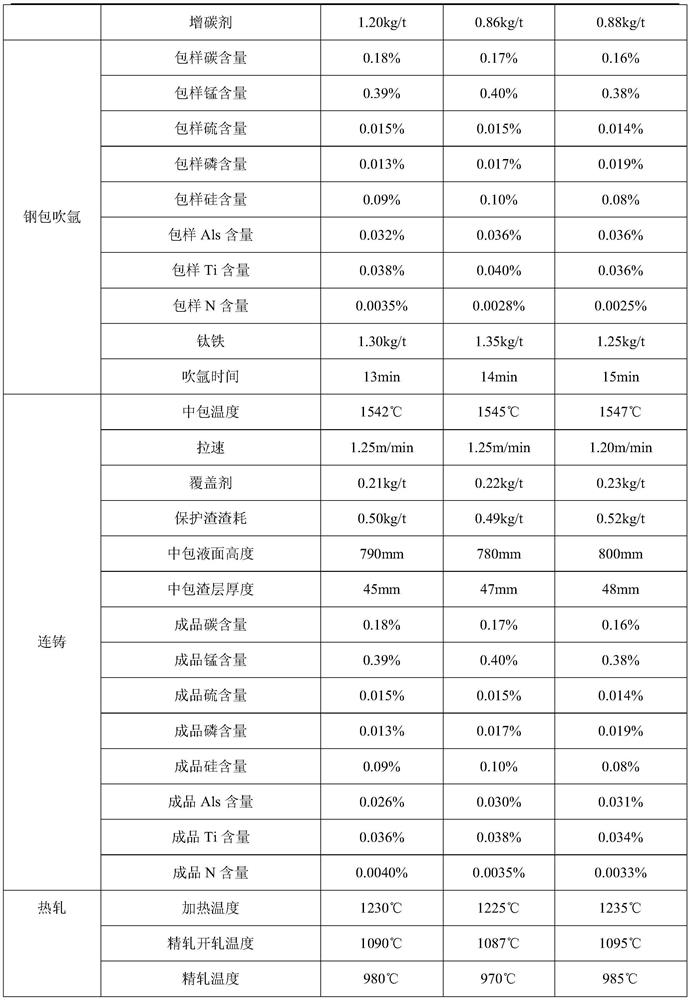

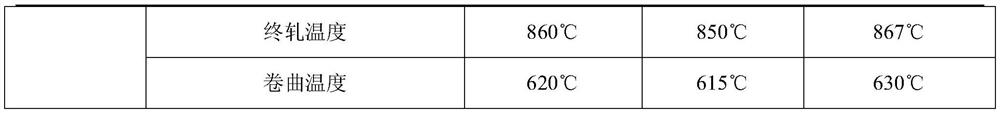

[0027] Each embodiment sees the following table:

[0028]

[0029]

[0030]

[0031] The steel strip produced according to the above embodiment has good physical properties and user welding and hot working performance in the subsequent processing of the hot rolling mill, and low inclusion level, which stabilizes the yield of titanium element under non-refining conditions and simultaneously reduces The silicon-manganese content reduces the production cost and has good promotion value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com