Environment-friendly rust removal and prevention composition

A composition and environment-friendly technology, which is applied in the field of ferrous metal surface treatment, can solve the problems of extreme concentration, limited practical application, poor cleaning effect, etc., achieves little influence of temperature and medium, and improves the effect of corrosion inhibition and anticorrosion. The effect of a wide range of effective concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

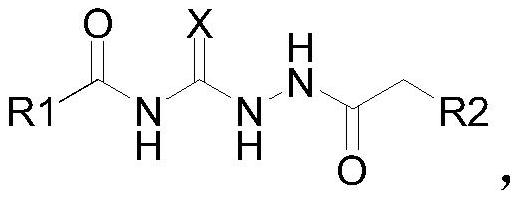

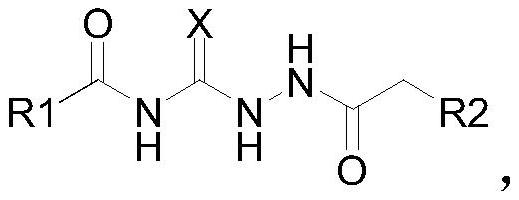

Method used

Image

Examples

Embodiment 1

[0027] An environment-friendly rust-removing and anti-rust composition, consisting of the following components in mass percentage:

[0028] Sulfamic acid: 13%

[0029] Phosphoric acid: 14%

[0030] Phytic acid: 0.15%

[0031] Hydroxyethylidene diphosphate: 0.95%

[0032] Ethanol: 4.5%

[0033] Disodium Lauroamphodiacetate: 0.35%

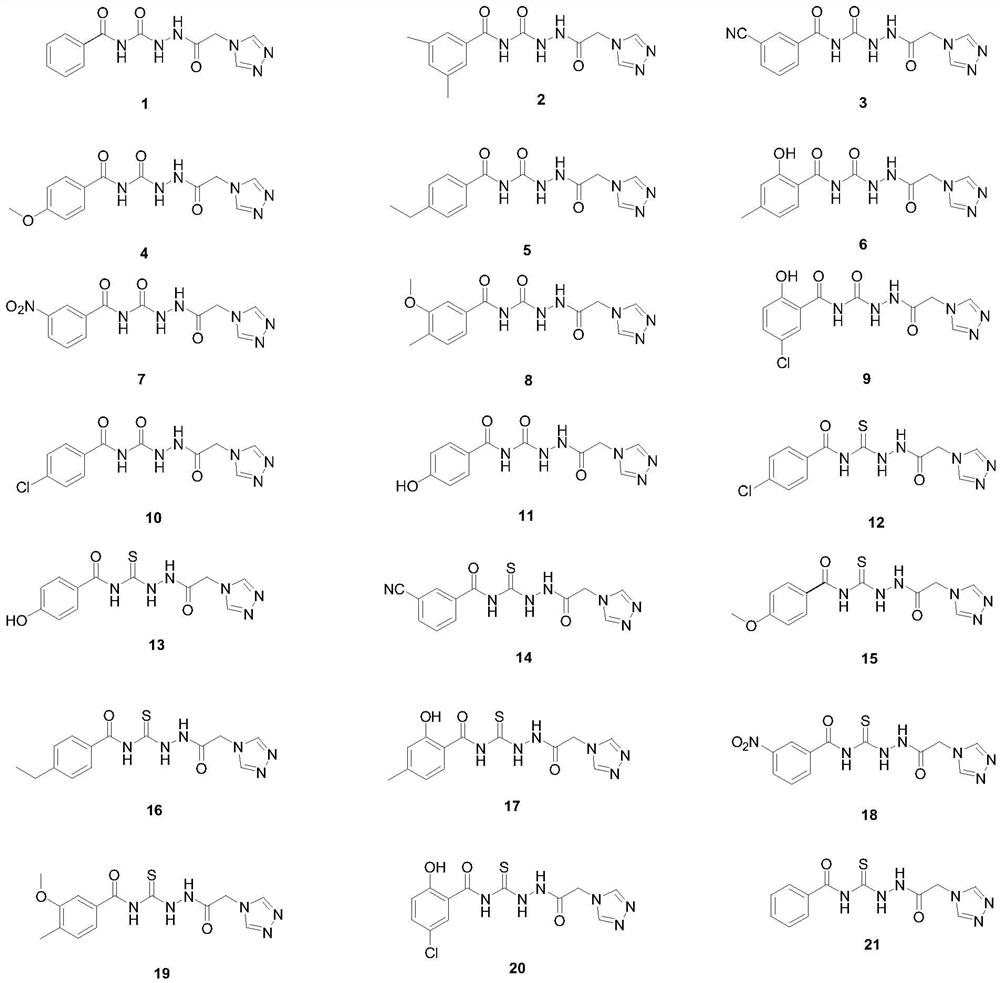

[0034] Urea derivative 13: 0.088%

[0035] n-Butanol: 0.55%

[0036] Polyferric sulfate: 0.08%

[0038] the rest is water

[0039] The above components were mixed and stirred until there was no insoluble matter to obtain the solution of Example 1.

Embodiment 2

[0041] An environment-friendly rust-removing and anti-rust composition, consisting of the following components in mass percentage:

[0042] Sulfamic acid: 12%

[0043] Phosphoric acid: 16%

[0044] Phytic acid: 0.15%

[0045] Hydroxyethylidene diphosphate: 1.0%

[0046] Ethanol: 6%

[0047] Disodium Lauroamphodiacetate: 0.35%

[0048] Urea Derivative 9: 0.088%

[0049] n-Butanol: 0.55%

[0050] Polyferric sulfate: 0.08%

[0052] the rest is water

[0053] The above components were mixed and stirred until there was no insoluble matter to obtain the solution of Example 2.

Embodiment 3

[0055] On the basis of Example 1, the urea derivative 13 was replaced by urea derivative 14 to obtain the solution of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com