Air-cooled galvanic pile environment simulation test system and control method thereof

An environmental simulation and testing system technology, applied in circuits, measuring devices, fuel cells, etc., can solve the problems of increasing the number of space ventilation, energy consumption of large vacuum ventilation, and increasing ventilation emissions, so as to reduce ventilation energy. The effect of reducing power consumption, reducing volume and facilitating stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

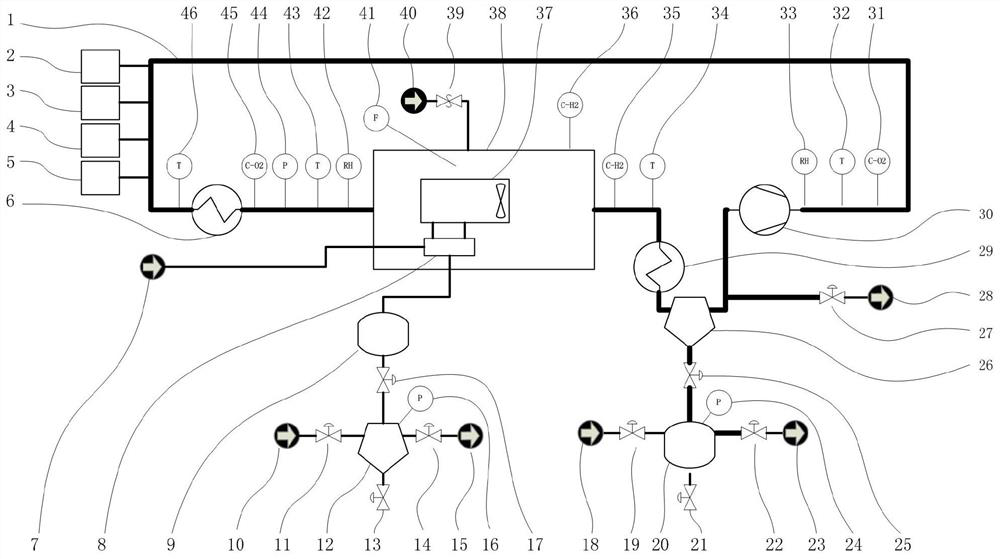

[0042] exist figure 1 Among them, the environmental simulation test device of the air-cooled stack consists of the main body of the test device equipped with the stack to be tested, that is, the environmental chamber 38 where the air-cooled stack 37 to be tested is placed, the hydrogen management system connected to the environmental chamber 38 and the external air management system. system composition.

[0043] The ambient simulated air in the external air duct system enters and exits from the opposite side of the environmental chamber 38. For the convenience of expression, the air enters from the left side and flows out from the right side in this figure, which is a non-limiting relative orientation. The air-cooled electric stack 37 to be tested is placed in the middle of the environmental chamber 38. The air-cooled electric stack 37 has the same fan induction direction as the aforementioned left-in and right-out. There is a gap between the air-cooled electric stack 37 and t...

Embodiment 2

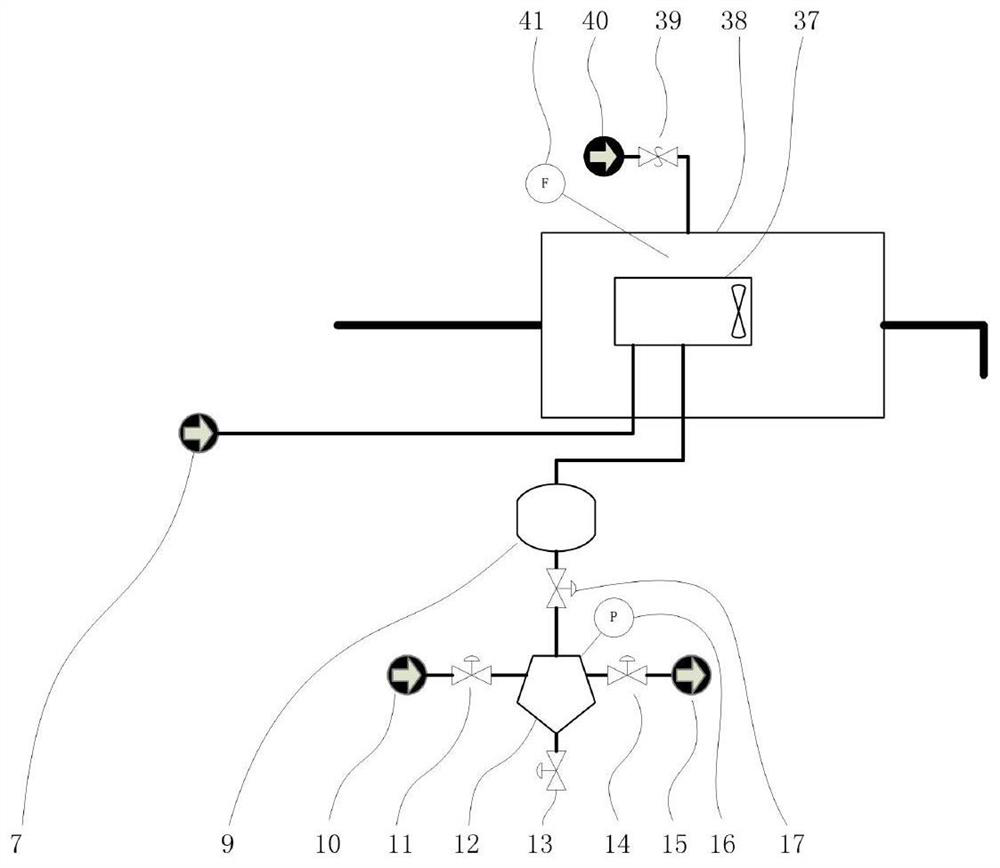

[0048] Such as figure 2 As shown, different from Example 1, the tested air-cooled stack 37 in this example has its own hydrogen management system to control the discharge of hydrogen by itself, and the environmental simulation test device of the air-cooled stack 37 only provides the hydrogen source 7, but does not provide The electric stack has its own hydrogen controller 8, and the hydrogen discharge generated by the air-cooled electric stack 37 directly enters the tail gas buffer 9, and the rest are the same as in the first embodiment.

Embodiment 3

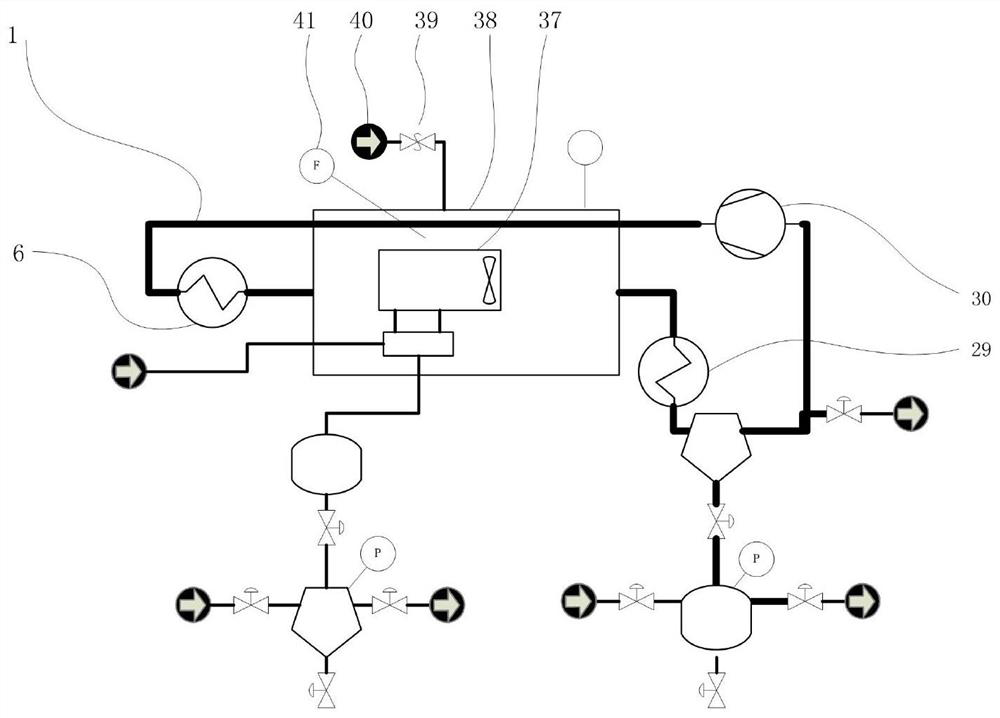

[0050] Such as image 3 As shown, the circulation pipeline 1 passes through the interior of the environment chamber 38 after passing through the circulation fan 30 , and then enters into the interior of the environment chamber 38 through the temperature raising heat exchanger 6 . This layout reduces the overall external dimensions compared to that of Embodiment 1. Other hydrogen exhaust gas management systems, various sensors, and other parts of the air management system that do not pass through the environmental chamber 38, and their relative positions and functions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com