Valve static pressure life automatic test device based on gasification booster

An automatic testing device and valve technology, applied in valve devices, mechanical valve testing, engine components, etc., can solve the problems of complex operation, low degree of automation, high energy consumption, etc., achieving high degree of automation, easy control, and saving labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

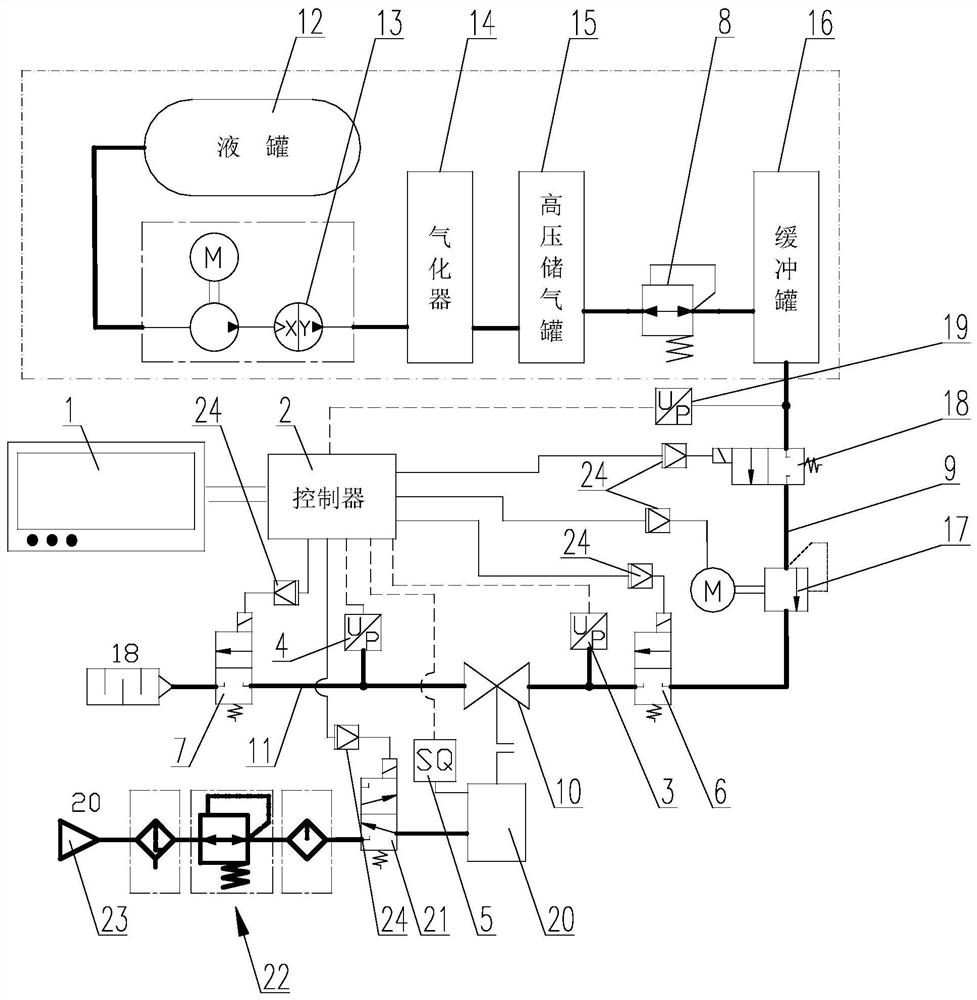

[0036] Such as figure 1 As shown, an automatic test device for valve static pressure life based on gasification boosting, including:

[0037] The control system has a controller 2 and a detection component, and the detection component includes an inlet pressure sensor 3, an outlet pressure sensor 4 and a travel switch 5 respectively connected to the controller 2;

[0038] Gas source pressurization system, used to vaporize and pressurize liquid gas to output high-pressure gas;

[0039] The loading system has an inlet switch valve 6, an outlet switch valve 7 and a pressure reducing valve 8, and the inlet switch valve 6, the outlet switch valve 7 and the pressure reducing valve 8 are respectively connected to the controller 2 with signals, and the pressure reducing valve The pressure valve 8 is arranged in the air source pressurization system, and is used to control the pressure of the high-pressure gas output by the air source pressurization system;

[0040]The drive system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com