Automatic lithium battery conveying and fixing equipment and conveying and fixing method thereof

A fixed equipment and lithium battery technology, applied in metal processing equipment, grinding/polishing equipment, conveyors, etc., can solve problems such as unfixable lithium batteries, shaking of lithium batteries, poor grinding effect, etc., to achieve fast transmission and fixing and The effect of grinding, saving manpower, improving grinding efficiency and grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

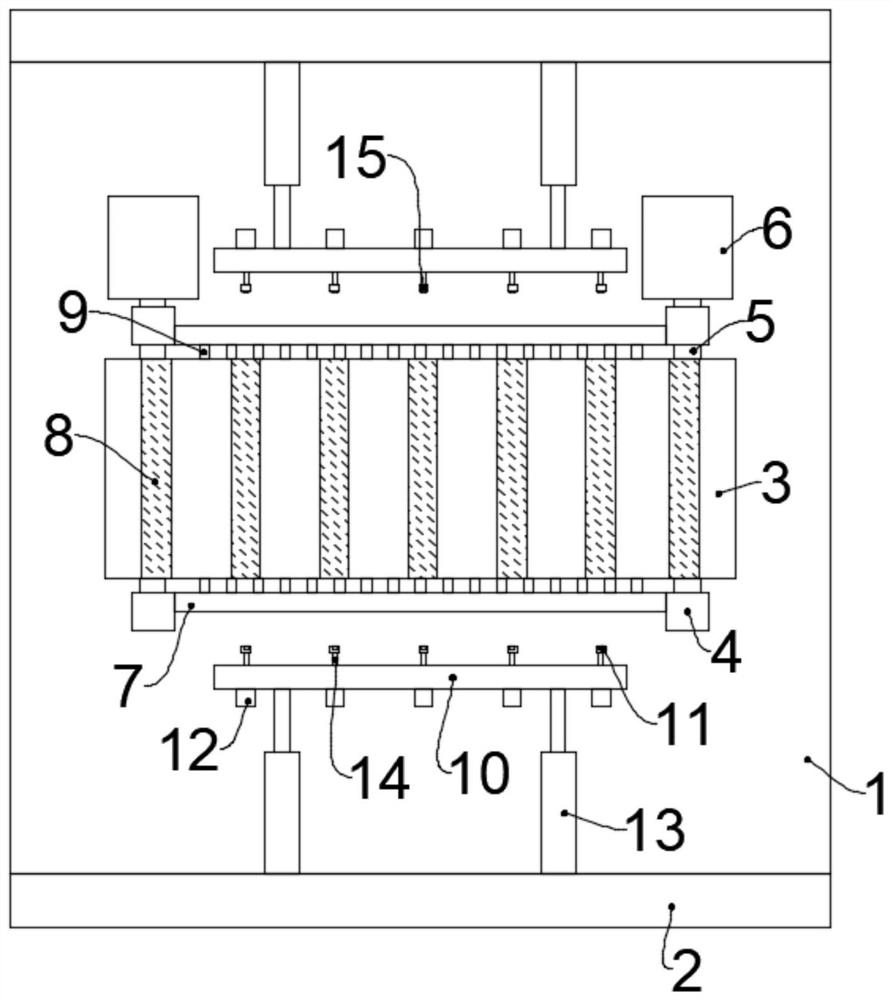

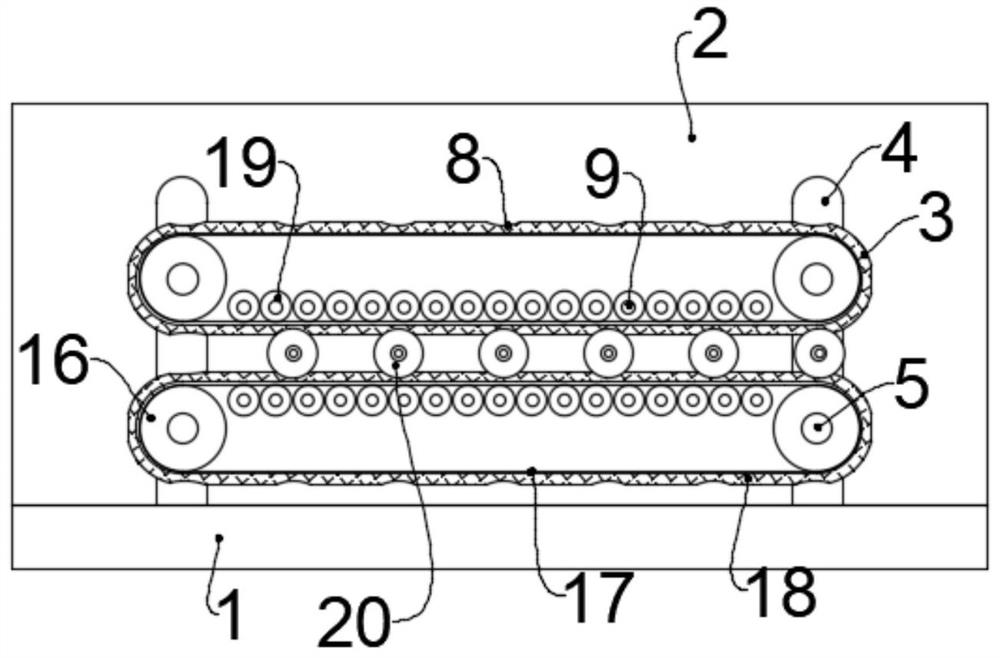

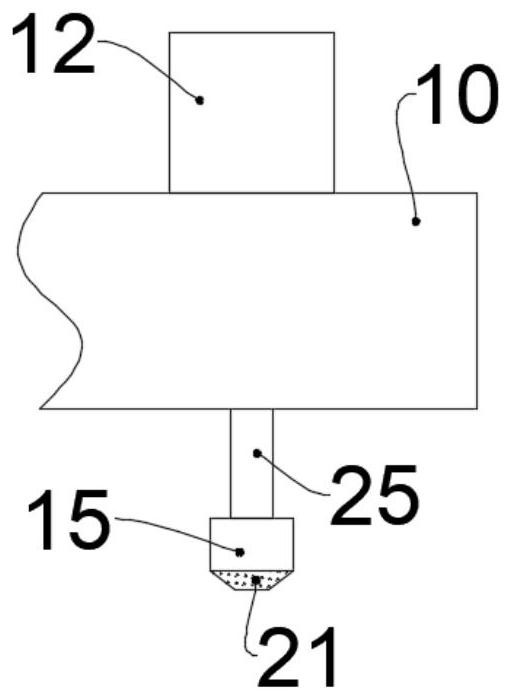

[0030] Such as Figure 1-5 As shown, a lithium battery automatic transmission and fixing device and its transmission and fixing method include a fixed base 1 for supporting and fixing, two support plates 2 are arranged on both sides of the fixed base 1, and the two support plates 2 are connected with the fixed base 1 Set vertically, two upper and lower conveyor belts 3 are arranged in the middle of the fixed base 1, and the upper and lower conveyor belts 3 are arranged parallel to each other. By changing the rotation direction of the two drive motors 6, the rotation directions of the two conveyor belts 3 are opposite. Conveyor belt 3 is arranged between two support plates 2, and conveyer belt 3 comprises friction belt 17, and the outside of friction belt 17 is provided with elastic rubber 18, and elastic rubber 18 runs along with the running of friction belt 17, and is provided between two conveyer belts 3. There are a plurality of lithium batteries 20 equidistantly distribute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap