High-modulus rapid repairing and reinforcing material for cave depots

A technology of reinforcement material and high modulus, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex performance requirements of coatings, and achieve the effect of good reinforcement, not easy to vibrate and fall off, and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

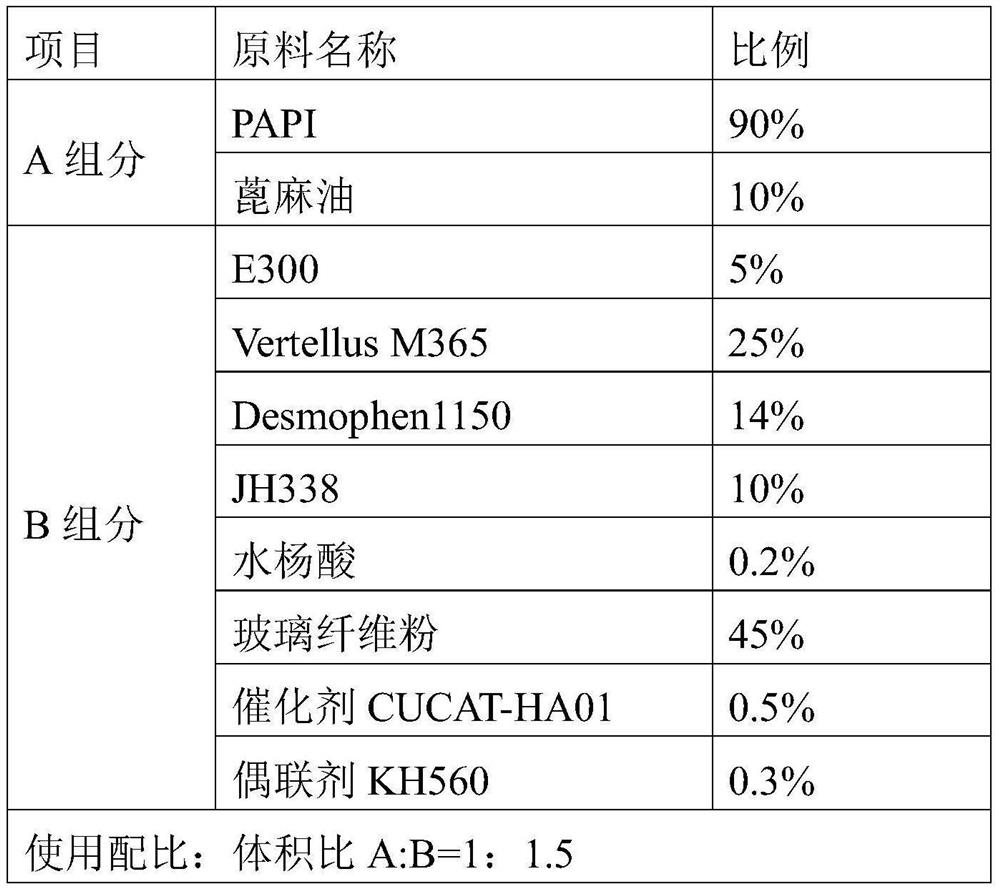

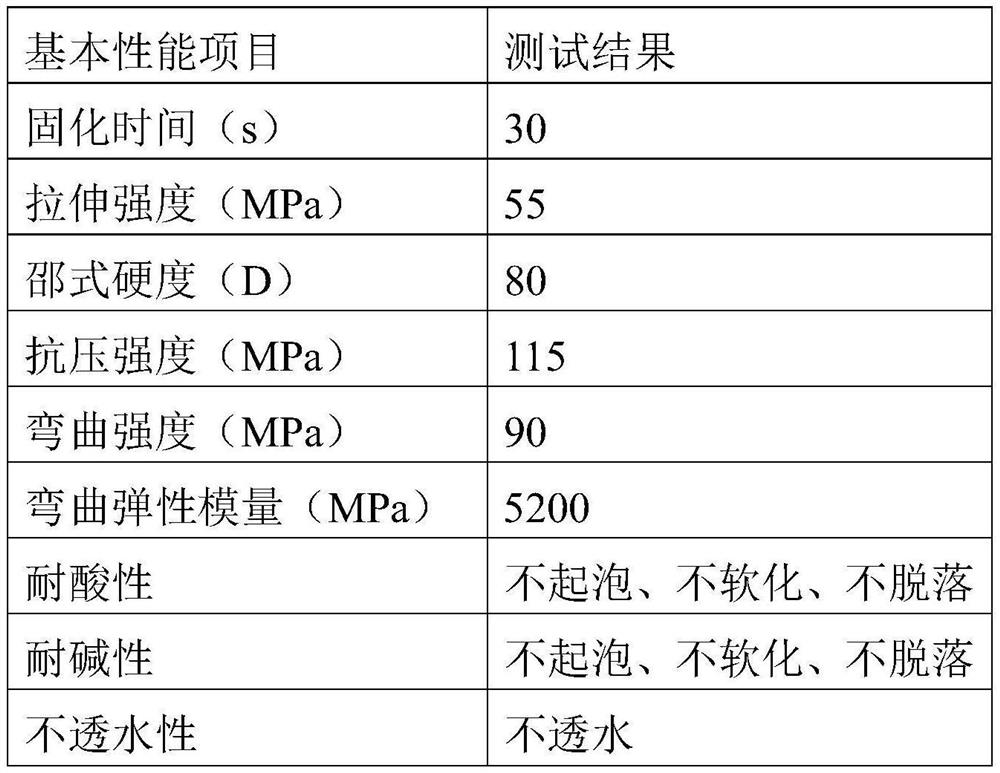

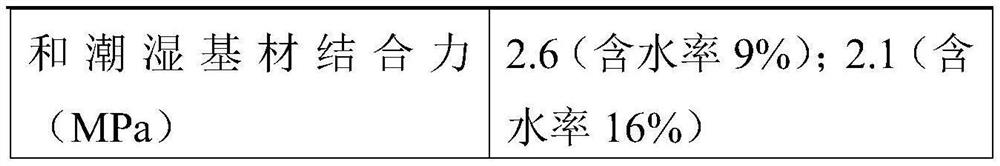

Embodiment 1

[0052] Preparation of component A:

[0053] Take 10 parts of refined castor oil by weight, put it into the reaction kettle, dehydrate under reduced pressure at 100-120°C for 1 hour, then cool down to 60°C, then slowly add 90 parts of PAPI, and slowly heat up to 70°C after half an hour of reaction and keep the temperature for 2 hour, when the free NCO content of the sampling test reaches 26.7%, the cooling filter discharges the material.

[0054] Preparation of component B:

[0055] Bake and dehydrate the glass fiber powder with an aspect ratio of 10:1 at 110-120°C for 2 hours, then spray KH560 on the glass fiber powder, stir and disperse at high speed at 3000r / min, stir for 20-30 minutes, then 120 Bake at ℃ for 2 hours and set aside.

[0056] 5% chain extender E300 by weight, 25% 4-functional hydrophobic polyol Vertellus M365, 14% Desmophen1150, 10% latent curing JH338, 0.2% hydrolysis accelerator salicylic acid, 0.5% catalyst CUCAT - HA01, 45.3% KH560 modified glass fiber ...

Embodiment 2

[0064] A component directly chooses PAPI, NCO% ≈ 31.

[0065] Preparation of component B:

[0066] Bake and dehydrate wollastonite powder with an aspect ratio of 15:1 at 110-120°C for 2 hours, then spray KH560 on the wollastonite powder, stir and disperse at high speed at 3000r / min, stir for 20-30 minutes, then 120 Bake at ℃ for 2 hours and set aside.

[0067] 8% chain extender E200 by weight, 8% 4-functionality hydrophobic polyol Vertellus M365, 21% 750, 4% TAE285, 10% latent curing agent JH306, 0.2% hydrolysis accelerator salicylic acid, 0.5% catalyst CUCAT-HA01, 48.3% KH560 modified wollastonite powder, put into the mixing tank, high speed Stir to disperse evenly at a speed of 1500r / min or more, stir for 1 hour, and filter out the material with an 80-mesh filter.

[0068] The raw material parameters are shown in Table 3, and the performance parameters are shown in Table 4.

[0069] Table 3. Embodiment 2 raw material parameters

[0070]

[0071] Table 4. Embodiment ...

Embodiment 3

[0075] Preparation of component A:

[0076] Take 3 parts by weight of polyether polyol TDIOL2000 with a molecular weight of 2000, put it into the reaction kettle, dehydrate under reduced pressure at 100-120°C for 1 hour, then cool down to 60°C, then slowly add 12 parts of LMDI, and slowly heat up after half an hour of reaction Keep warm at 70°C for 2 hours, then add 85 parts of PAPI, take a sample and test when the free NCO content reaches 29.8%, cool down and filter to discharge.

[0077] Preparation of component B:

[0078] Bake and dehydrate the glass fiber powder with an aspect ratio of 10:1 at 110-120°C for 2 hours, then spray SI69 on the glass fiber powder, stir and disperse at high speed at 3000r / min, stir for 20-30 minutes, then 120 Bake at ℃ for 2 hours and set aside.

[0079] 5% chain extender E100 by weight, 10.5% 4-functionality hydrophobic polyol Vertellus M365, 14.2% TAE305, 17.3% Desmophen1150, 12% latent curing agent JH338, 0.2% salicylic acid hydrolysis acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com