Strip steel pickling device and method

A steel acid and strip steel technology, applied in the field of strip steel pickling equipment, can solve the problems of high energy consumption, pipeline impact, high cost, etc., and achieve the effects of improving descaling efficiency, improving acid activity, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

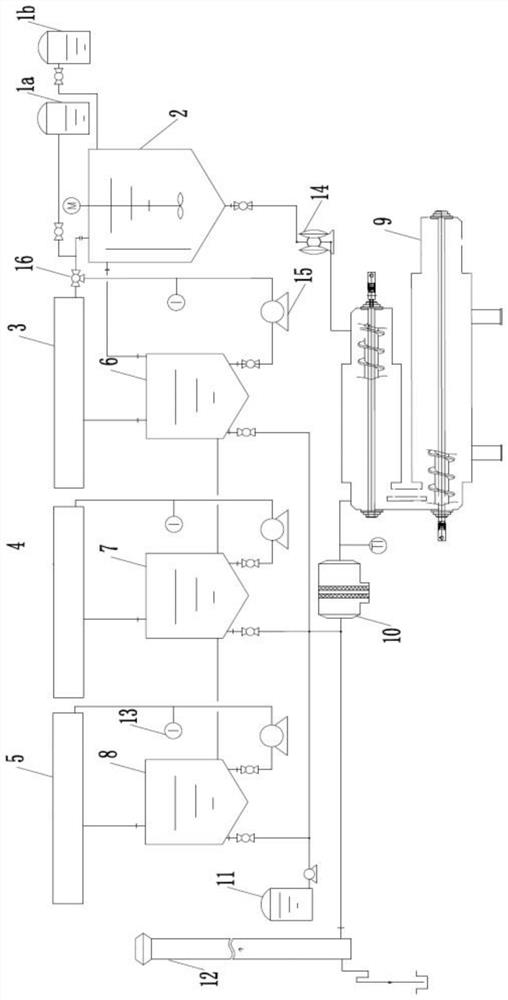

[0032] Such as figure 1 As shown, a strip pickling device can include multi-acid dosing tank 1a, flocculant dosing tank 1b, online standby acid tank 2, three pickling tanks (that is, inlet pickling tank 3, intermediate pickling tank 4 and outlet pickling tank 5), three acid tanks (namely, inlet acid tank 6, intermediate acid tank 7 and outlet acid tank 8), drying system 9, condensation system 10 and oxidation control system, etc.

[0033] The polyacid dosing tank 1a and the flocculant dosing tank 1b form a chemical dosing system, which is used to add the polyacid and flocculant into the online standby acid tank 2 . The polybasic acid may include one or a combination of oxalic acid, citric acid, and tannic acid. The flocculant can be cationic polyacrylamide and the like. The content of acid and metal ions in the acid solution is controlled by the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com