System device for producing acetic acid from byproduct methyl acetate of production of polyvinyl alcohol and preparation method

A technology of methyl acetate and system device, applied in the chemical field, can solve the problems of high energy consumption, complicated operation, long process flow, etc., and achieve the effects of saving energy consumption, reducing the amount of steam, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

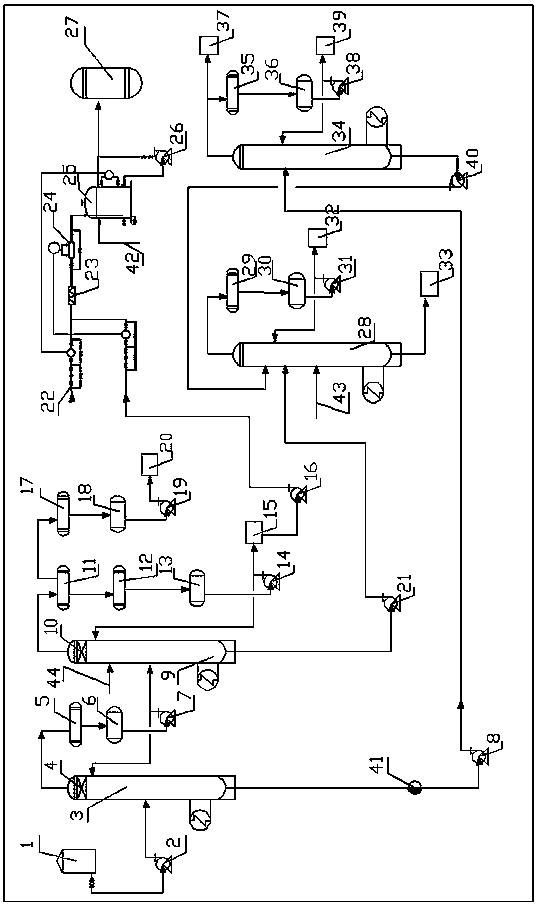

[0046] The specific embodiment of the invention is combined with the attached figure 1 for further description

[0047] like figure 1 Shown, a kind of system device that utilizes polyvinyl alcohol by-product methyl acetate to produce acetic acid, this system device comprises recovery one tower 3; Recovery two tower 9; Recovery three tower 28; Recovery four tower 34; Methanol, methyl ester mixing tank 25 and acetic acid reactor 27. The raw liquid storage tank 1 is connected with the first recovery tower 3 through the feeding pump 2, and the demister 4 is installed on the top of the first recovery tower 3, and is connected with the first tower distillation condenser 5, the first tower distillation tank 6, and the first tower distillation through pipelines. The outlet pumps 7 are connected to each other, and then connected to the recovery second tower 9 through the first tower distillation pump 7. The demetallization ion assembly 10 is installed on the top of the second recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com