Processing method of vacuum equipment adopting laser cladding technology

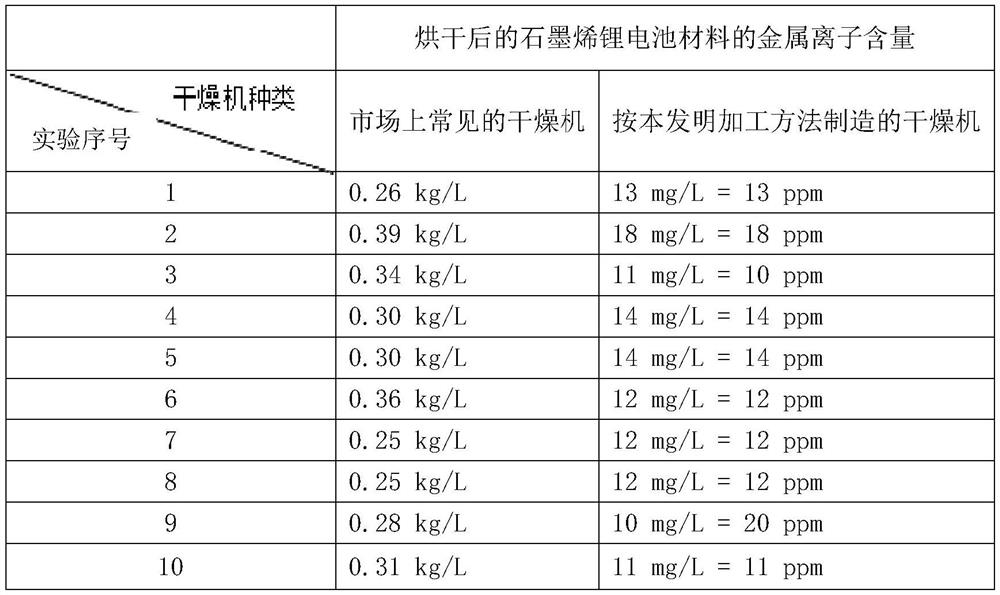

A technology of laser cladding and vacuum equipment, applied in lighting and heating equipment, metal material coating process, drying solid materials without heating, etc., can solve the problems of excessive metal ion content, affecting the quality and performance of end products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A processing method for vacuum equipment using laser cladding technology, comprising the following steps:

[0022] 1) Laser cladding treatment on the inner wall of the vacuum drying tank: the robot holds the laser and works in the vacuum drying tank, and adds the cladding material to the substrate after laser irradiation by synchronous or preset cladding materials In the formed molten pool, and make the two rapidly solidify together to form a cladding layer on the inner wall of the vacuum drying tank, the cladding material is silicon carbide or tungsten carbide;

[0023] 2) Carry out pore filling treatment on the cladding layer: there are countless particle gaps on the cladding layer, and a pore filling agent is filled into each particle gap and solidified. The pore filling agent is polyimide, bismuth Phenol A epoxy resin, polyphenylene sulfide, polyether ether ketone, or phenolic resin.

[0024] The cladding material can also be other wear-resistant, high-temperature-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com