Anti-ultraviolet textile fabric and preparation method thereof

A textile fabric, anti-ultraviolet technology, applied in the field of textile fabrics, can solve the problems of easy breeding of bacteria, inability to resist ultraviolet rays, and reduce performance, so as to achieve the effect of being less prone to bacterial growth, beneficial to human health, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

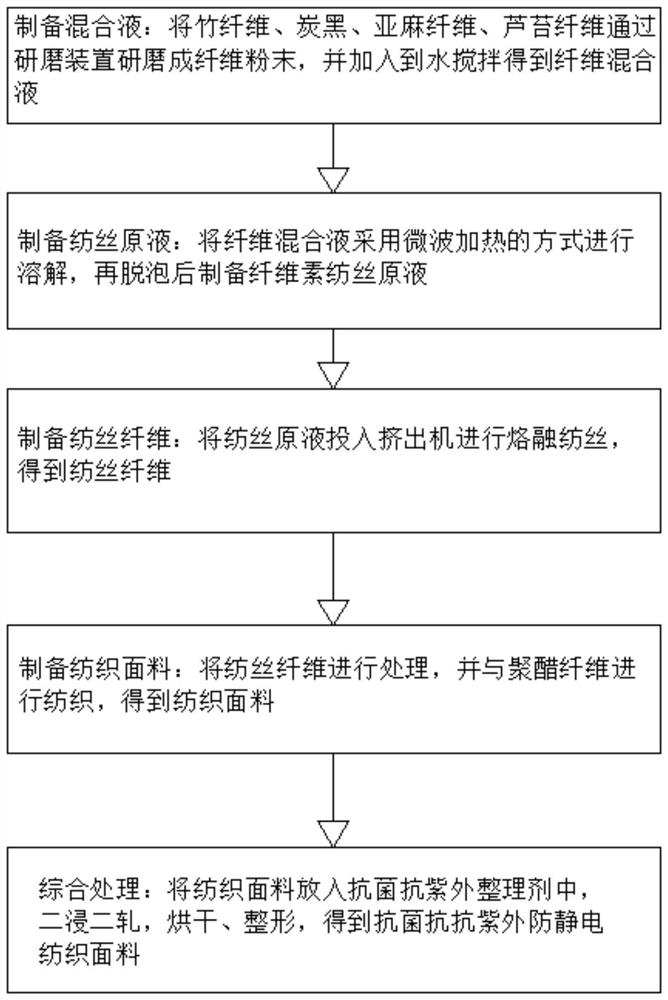

[0037] see Figure 1-8 , the present invention provides a technical solution: a preparation method of an anti-ultraviolet textile fabric, which consists of the following steps:

[0038] Step 1. Preparation of mixed solution: grinding bamboo fiber, carbon black, flax fiber and reed fiber through a grinding device into fiber powder, and adding to water and stirring to obtain fiber mixed solution;

[0039] Step 2, preparing the spinning stock solution: dissolving the fiber mixture by microwave heating, and then preparing the cellulose spinning stock solution after defoaming;

[0040] Step 3, preparing spun fibers: putting the spinning stock solution into an extruder for melt spinning to obtain spun fibers;

[0041] Step 4, preparing textile fabrics: processing the spun fibers, and spinning them with polyester fibers to obtain textile fabrics;

[0042]Step 5. Comprehensive treatment: put the textile fabric into the antibacterial and anti-ultraviolet finishing agent, dipping and ...

Embodiment example 2

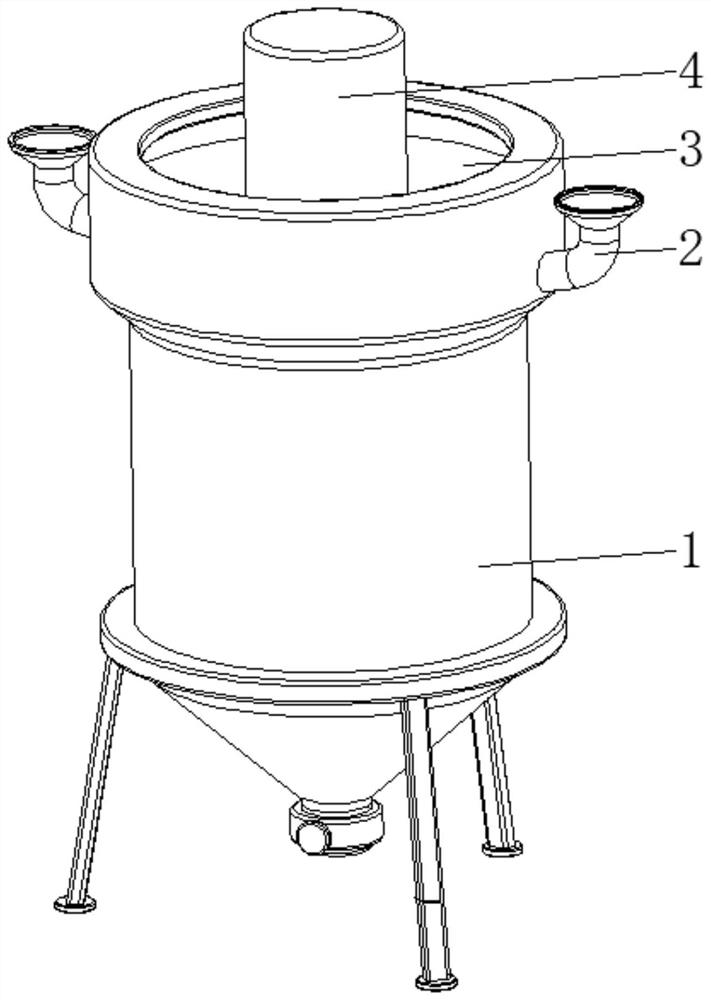

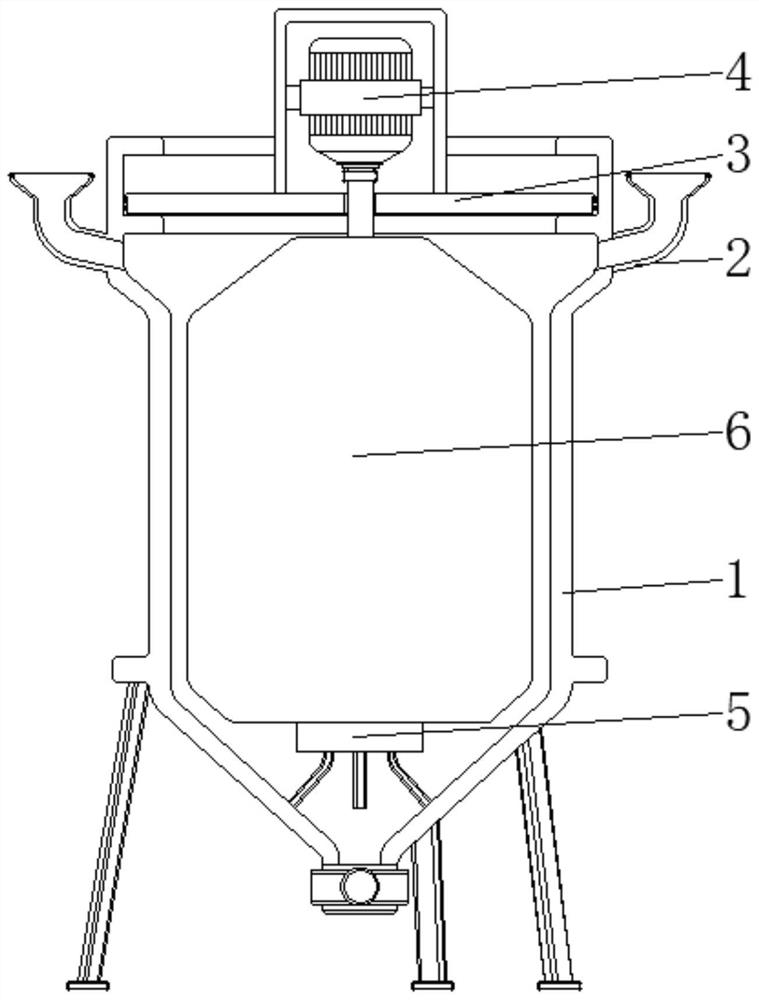

[0044] The grinding device includes a body 1, the two sides corresponding to the top of the surface of the body 1 are fixed and connected to the feed hopper 2, the inside of the body 1 and near the top is provided with a disc 3, and the top center of the disc 3 is provided with a power mechanism 4. The bottom of the inner wall of the body 1 is provided with a turntable device 5, and the top of the turntable device 5 is provided with a grinding core device 6. Rotate and connect between them, the top of the grinding core device 6 runs through the circular plate 3 and extends to its top and is connected with the power mechanism 4, and the grinding core device 6 is driven by the power mechanism 4, so that bamboo fiber, carbon black, Raw materials such as flax fiber and reed moss fiber are ground in multiple directions, which makes the grinding efficiency high, and uses its own rotation to link the structure together, preventing the raw material powder from sticking and improving th...

Embodiment example 3

[0046] The rotating disk device 5 is provided with a bottom fixed disk 51, an arc surface protrusion 52, a top rotating disk 53, and a rolling ball 54. The bottom of the bottom fixed disk 51 is fixedly connected with the bottom of the inner wall of the body 1, and the arc surface protrusion 52 is arranged on the bottom fixed disk. 51, the top rotating disk 53 is connected to the surface of the bottom fixed disk 51, and the rolling ball 54 is arranged on the top of the inner wall of the top rotating disk 53 and is positioned at the top of the bottom fixed disk 51. When the grinding cylinder 61 is rotating the abrasive material, the top rotating disk 53 will also rotate accordingly, and then the rolling ball 54 will move. When rotating, the top rotating disk 53 will be lifted up by the arc surface protrusion 52. Furthermore, the grinding cylinder 61 can move up and down reciprocatingly under the condition of its own rotation, thereby increasing the grinding square of the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com