New energy vehicle power test system

A technology for a new energy vehicle and a test system, which is applied in the field of the power test system of the whole new energy vehicle, can solve the problems of troublesome installation, great danger, and can not meet the simulation of complex operating conditions and complex road conditions, and achieves a simple structure, Debug alignment simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings and embodiments.

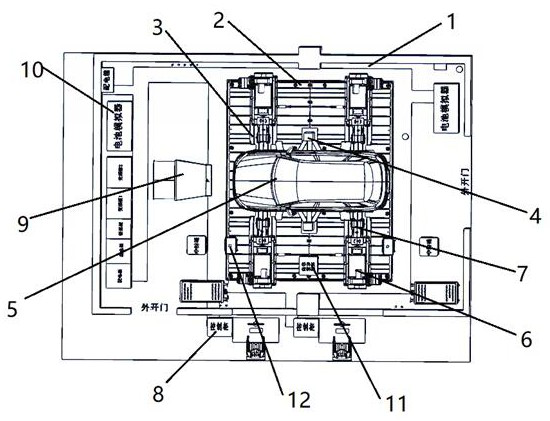

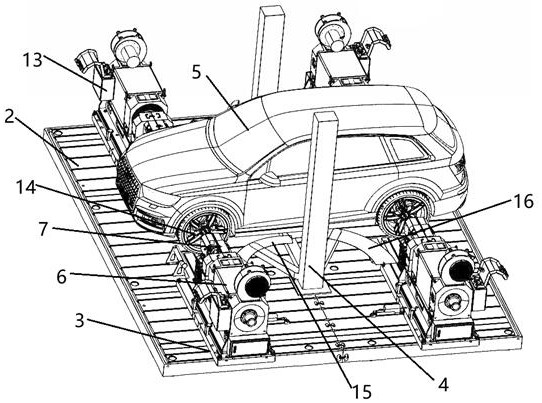

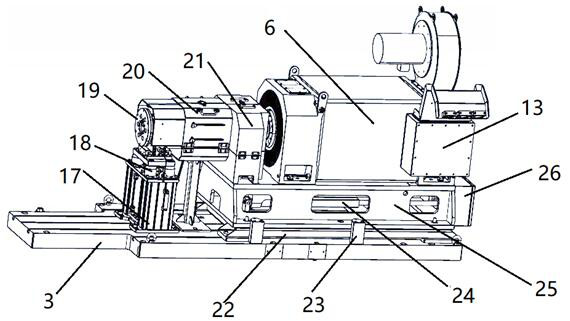

[0043] This example: see Figure 1 to Figure 5 , The power test system of the new energy vehicle includes a workbench 1, and a lifting frame that can drive the new energy vehicle 5 to move along the height is arranged on the workbench 1. The workbench 1 corresponds to the four hubs 14 of the new energy vehicle 5. , is provided with four attitude frames 7 that can move radially and / or axially, the attitude frame 7 is provided with a rotating head that can adjust the angle of pitch and axial fine-tuning, and one end of the rotating head is provided with a new energy vehicle after lifting The connecting end 19 of the wheel hub 14 of 5 is detachably connected, and the other end is provided with a rotating shaft connected with the power device in the dynamometer 6, and the power device can drive the wheel hub 14 of the new energy vehicle 5 to rotate through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com