Synthetic material powder and application thereof in hemostatic system

A technology of synthetic materials and powders, applied in applications, surgical adhesives, medical science, etc., can solve the problems of no interaction between tissues, low strength of colloids, inconvenient use, etc., and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

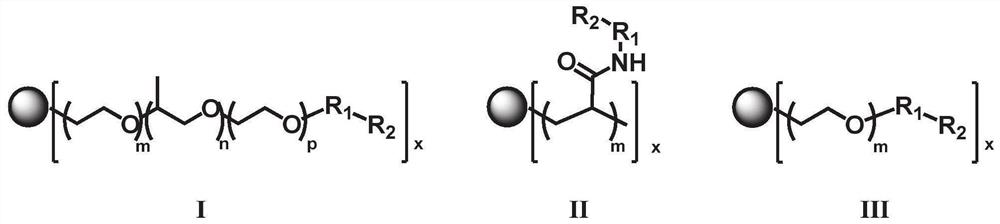

[0036] Take by weighing 140mg four-arm polyoxyethylene polyoxypropylene succinimide activated ester (as shown in formula I, wherein, m is 36, n is 21, p is 2, x is 4, R 1 is an ester bonded 2-carbon alkyl chain, R 2 succinimide activated ester), with a particle size of 2 μm, weighed 110 mg of aminochitosan, with a particle size of 2 μm, and mixed the synthetic powder and chitosan powder evenly to obtain a composite hemostatic powder.

[0037] Degradation test: Put the composite hemostatic powder after water absorption into 10 times the mass of PBS solution, then put it in a constant temperature shaker at 37±1°C, observe the gel sample in the buffer solution at a speed of 100r / min Change the situation until the time when no precipitation is seen by centrifugation, which is recorded as the degradation time of the gel in vitro.

[0038] The composite hemostatic powder prepared in this example has a water absorption capacity of 290 times the weight of the body. After absorbing wa...

Embodiment 2

[0040] Take by weighing 500mg four-arm polyacrylamide aldehyde group (as shown in formula II, wherein, m is 28, x is 4, R 1 is an ester bond, R 2 aldehyde group), the particle size is 0.2 μm, weigh 1 g of fibrin, the particle size is 0.5 μm, and mix the two powders evenly to obtain a composite hemostatic powder.

[0041] The composite hemostatic powder prepared in this example has a water absorption capacity of 300 times. After absorbing water, the composite hemostatic powder becomes jelly, and the degradation time in vitro is 3 days.

Embodiment 3

[0043] Take by weighing 100mg six-arm polyethylene glycol succinimide activated ester (as shown in formula III, wherein, m is 38, x is 6, R 1 is an amide bonded 2-carbon alkyl chain, R 2 succinimide activated ester) with a particle size of 2.5 μm, weighed 200 mg of commercially available chitosan hemostatic powder with a particle size of 2.5 μm, and mixed the two powders evenly to obtain a composite hemostatic powder.

[0044] The composite hemostatic powder prepared in this embodiment has a water absorption capacity of 200 times, which is close to the water absorption capacity (70 times) of a single commercially available chitosan hemostatic powder. After absorbing water, the composite hemostatic powder becomes jelly, and the degradation time in vitro for 4 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com