Four-tower triple-effect distillation dehydration device and method for preparing fuel ethanol from industrial tail gas fermentation mash

A technology for fermenting mash and fuel ethanol, which is applied in the field of alcohol distillation, can solve the problems of affecting the distillation efficiency, low alcohol concentration and high viscosity of the mash, and achieves the effects of improving the distillation efficiency, the process is reasonable, and the stability is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

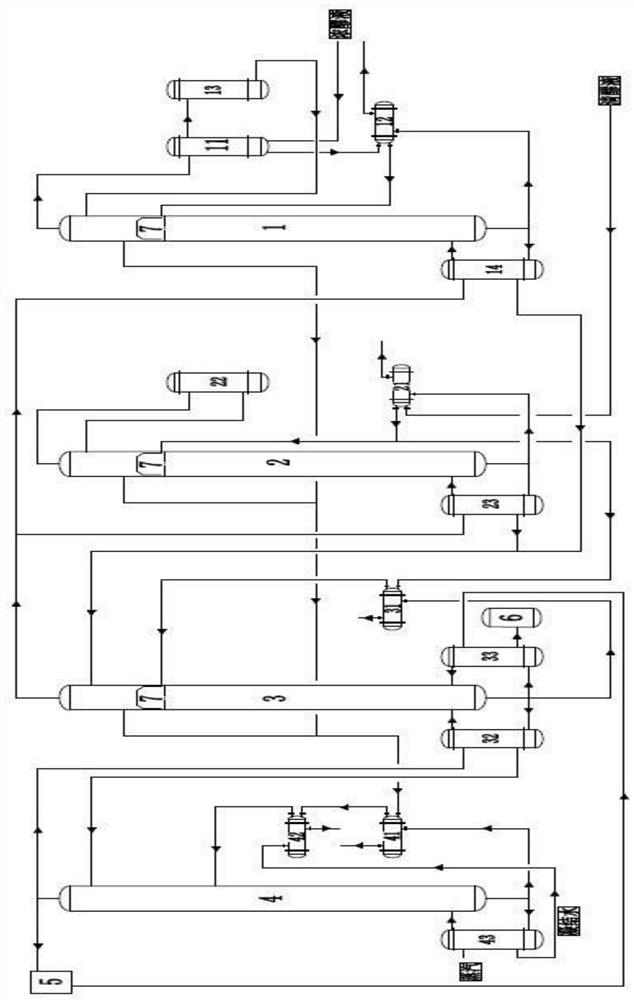

[0059] Utilize the method for preparing fuel ethanol by the device of the present invention:

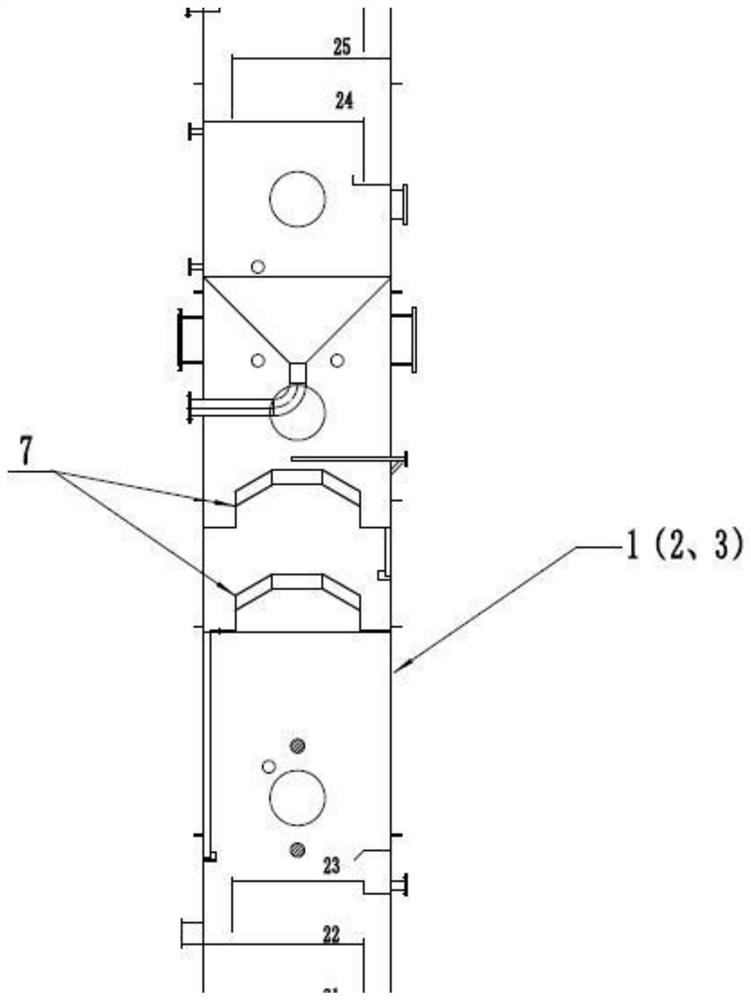

[0060] (1) The thick mash enters the thick mash tower through the thick mash wine vapor preheater and the thick mash distiller's grains preheater in turn for distillation, and the distilled wine vapor passes through the rectification tower feed preheater A and the rectification tower successively. The material preheater B enters the rectification tower for rectification, and the wine vapor after rectification enters the molecular sieve for dehydration;

[0061] The cleared mash enters the cleared mash tower B and the cleared mash tower A through the clear liquid preheater for distillation, and the distilled wine vapor passes through the rectification tower feed preheater A and rectification tower feed preheater B respectively Enter the rectification tower for rectification, and the wine vapor after rectification enters the molecular sieve for dehydration;

[0062] After dehydration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com