A kind of wet-mixed mortar and its preparation method and application

A technology of wet mixing mortar and river sand, applied in the direction of walls, building components, buildings, etc., can solve the problems of irresistibility, cracking of the plastering layer, deterioration of the quality of the plastering layer, etc., so as to reduce damage, reduce cracking, and reduce water loss. Effect

Active Publication Date: 2022-06-24

山东百纳混凝土有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of the above-mentioned related technologies, the inventor believes that: because the moisture of the mortar is easily absorbed by the aerated concrete blocks, the mortar of the plastering layer is not condensed, and cannot resist the tensile stress caused by volume shrinkage, which leads to cracking of the plastering layer, which in turn leads to poor quality of the plastering layer. decline

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

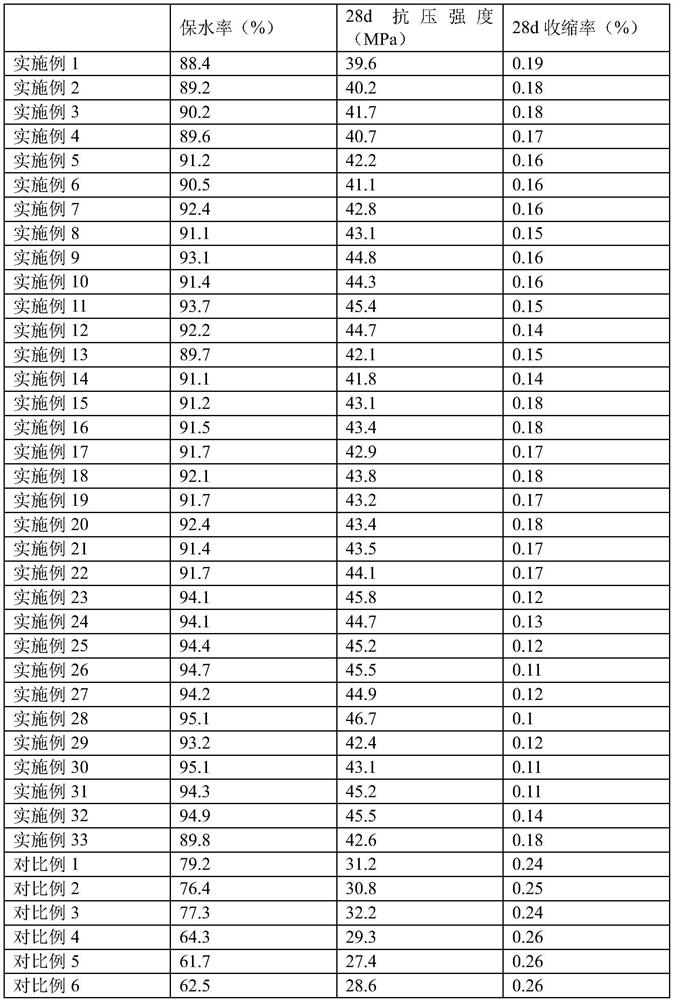

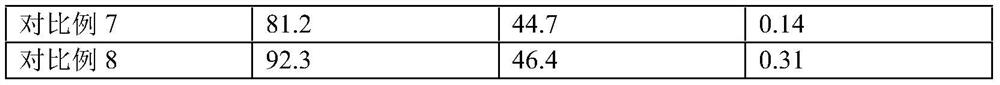

Effect test

preparation example 1

[0033] Weigh 400kg of industrial alkali slag and 200kg of sulfur-fixing ash, stir and mix evenly.

preparation example 2

[0035] Weigh 500kg of industrial alkali slag and 200kg of sulfur-fixing ash, stir and mix evenly, the fineness of the sulfur-fixing ash is 400 mesh, and then add 100kg of butyl acrylate, stir and mix evenly to obtain a water-retaining agent.

preparation example 3

[0037] Weigh 600kg of industrial alkali slag and 200kg of sulfur-fixing ash and stir and mix evenly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The application relates to the field of building materials, and specifically discloses a wet-mixed mortar and its preparation method and application. A wet-mixed mortar includes the following raw materials in parts by weight: 280-320 parts of cement, 70-90 parts of fly ash, 1320-1480 parts of river sand, 140-180 parts of drinking water, 5-15 parts of mortar superplasticizer, water retention The water retaining agent includes butyl acrylate, industrial alkali residue and sulfur-fixing ash, and the weight ratio of the three is 1: (4-6): (2-4). The wet-mixed mortar of the present application can be used for plastering indoor walls or outdoor walls, and has the advantages of increasing the water retention rate of the mortar, reducing the moisture absorbed by the aerated concrete blocks, reducing cracking of the plastering layer, and improving the quality of the plastering layer.

Description

technical field [0001] The present application relates to the field of building materials, more particularly, it relates to a wet-mixed mortar and its preparation method and use. Background technique [0002] Wet-mixed mortar refers to cement, sand, water-retaining and thickening materials, fly ash or other mineral admixtures, admixtures and water in a certain proportion after being measured and mixed in a centralized mixing station, and then transported by mixer trucks to Place of use, put it in a sealed container for storage, and use up the mortar mixture within the specified time. [0003] In the related art, the Chinese invention patent application with the publication number CB105776989A discloses a new type of wet-mixed mortar, which includes the following components in weight percentages: gas-setting hydraulic portland cement: 150kg / m 3 ~250kg / m 3 ; fly ash: 40kg / m 3 ~150kg / m 3 ; Machine-made sand: 1280kg / m 3 ~1300kg / m 3 ; Water: 184kg / m 3 ~276kg / m 3 . [000...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/04E04B2/00C04B24/04C04B103/46

CPCC04B28/04E04B2/00C04B40/0039C04B2103/465C04B2201/50C04B18/08C04B14/068C04B22/002C04B2103/302C04B24/045C04B18/04

Inventor 咸立军吕昌永陈盛强刘博

Owner 山东百纳混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com