Drilling machine capable of automatically ascending and descending drill rod and automatic control method

A technology of automatic drilling and drilling rods, which is applied to drilling equipment and methods, drilling rods, rotary drilling rigs, etc., which can solve the problems of hidden dangers to workers' health and safety, small number of rod replacements, high labor intensity, etc., and achieve easy drilling The effect of pressure relief operation, ensuring the number of drill pipes and reducing the movable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

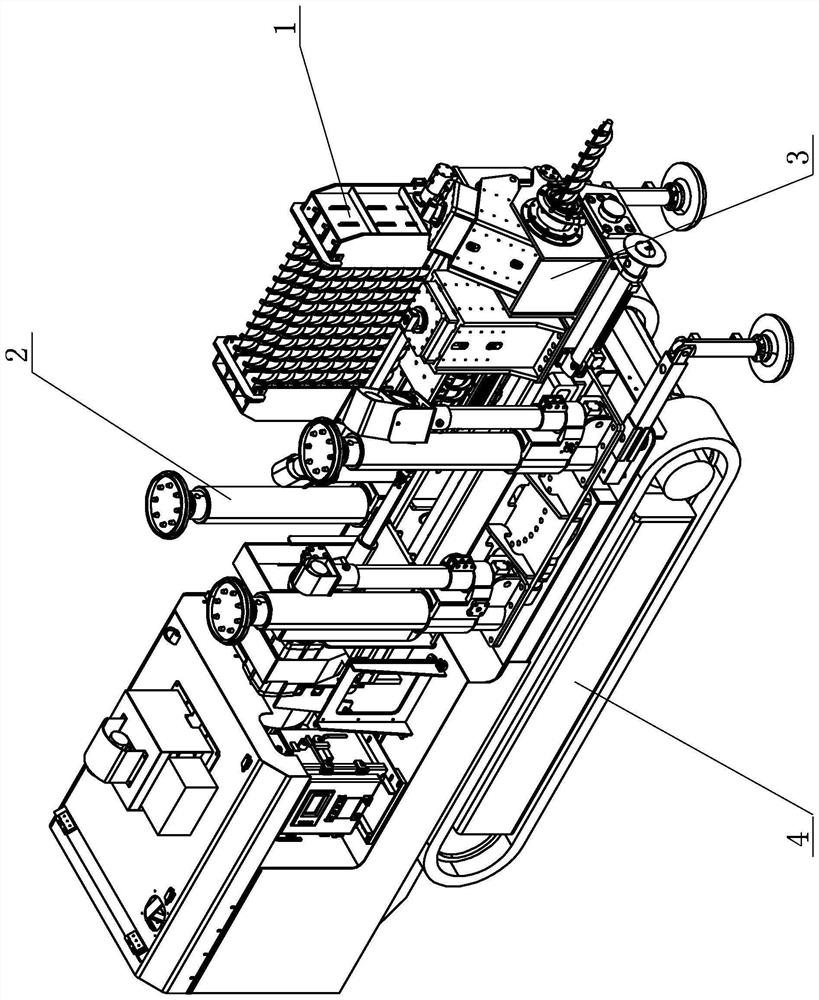

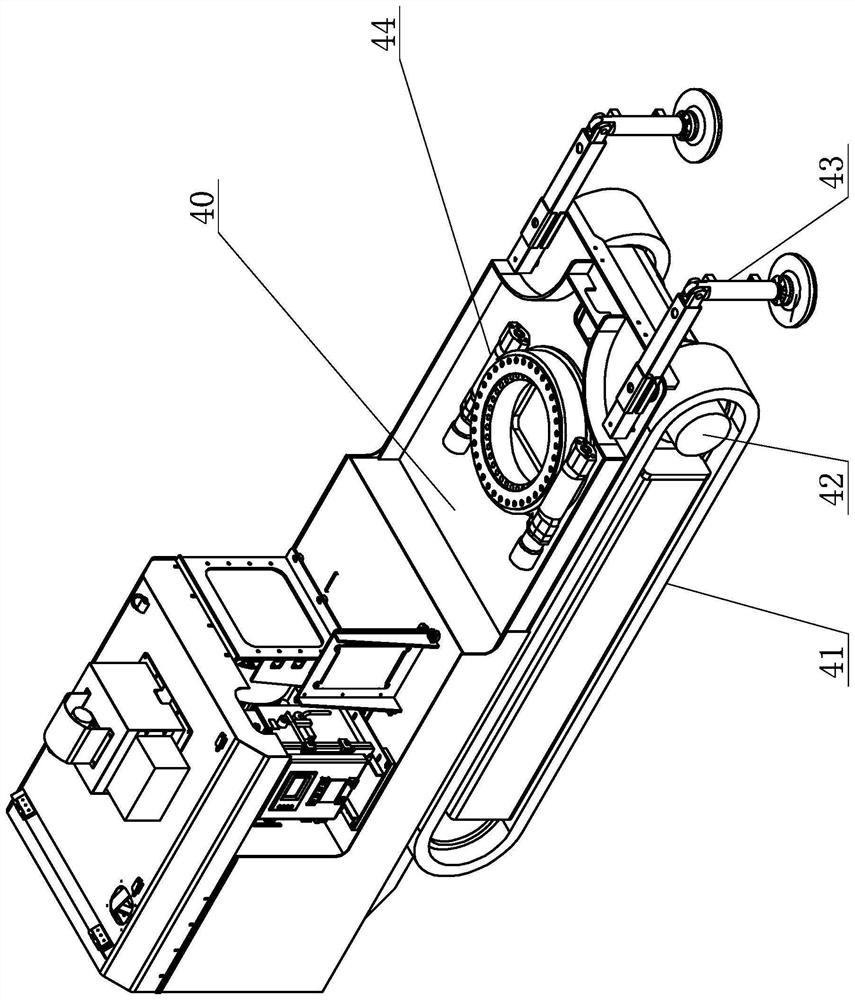

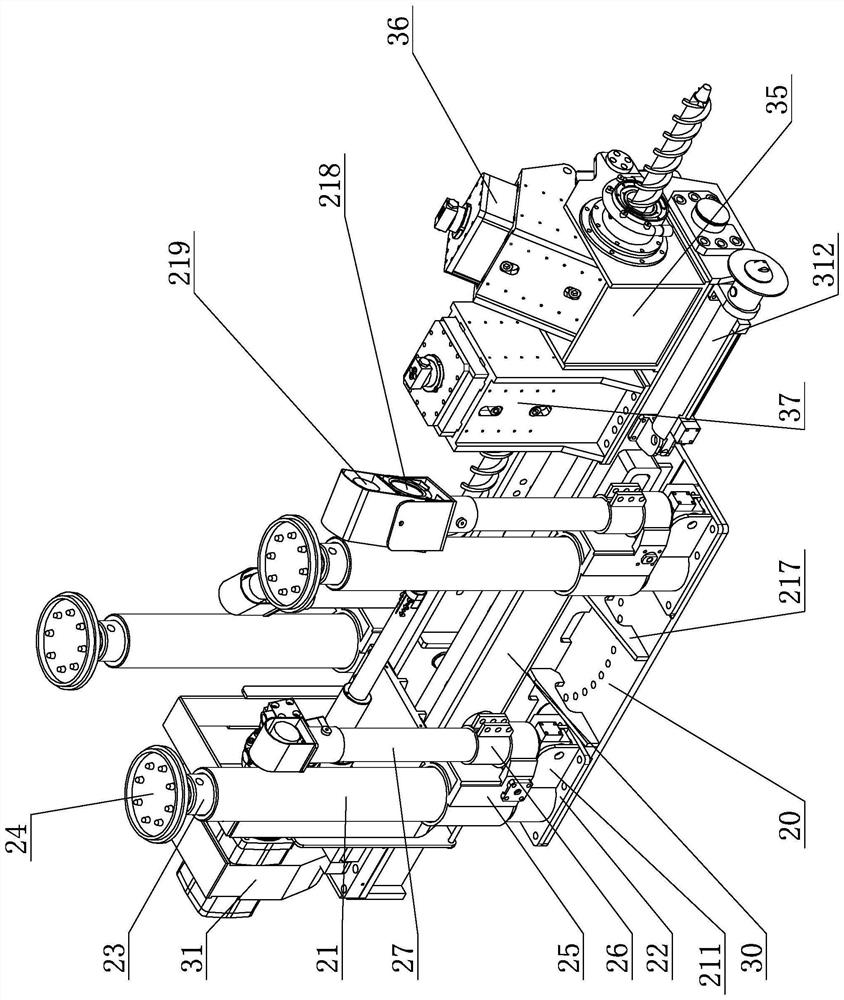

[0041] A kind of drilling rig that can automatically go up and down the drilling rod according to the present invention, such as figure 1 As shown, it includes a chassis walking unit 4, a support device 2, a drill pipe feeding device 3 and an automatic drill pipe box device 1. A support device 2 is installed on the chassis walking unit 4, and a drill pipe feeder is installed on the support device 2 The feeding device 3 is equipped with an automatic drilling rod box device 1 on the drill pipe feeding device 3, wherein the chassis traveling unit 4 can realize the movement of the whole machine in the roadway, and the supporting device 2 can rotate relative to the chassis traveling unit 4 to realize the support of the whole machine At the same time, it can also drive the drill pipe feeding device 3 on it to rotate synchronously, and adjust the position of the pressure relief drilling hole as required. The drill pipe feeding device 3 can move vertically on the support device 2, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com