Capecitabine polymer-lipid hybrid nanoparticle capable of utilizing micro-mixing and amphiphilic properties of capecitabine

A nanoparticle, capecitabine technology, applied in the field of nanoparticles, can solve problems such as delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] Example 1: Preparation of CAP nanoparticles

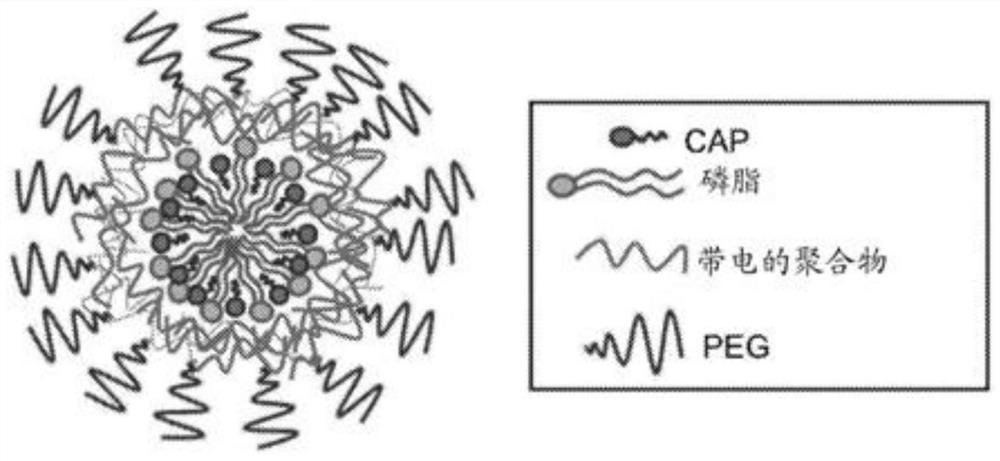

[0135] Structure of polymer-lipid nanoparticles of CAP

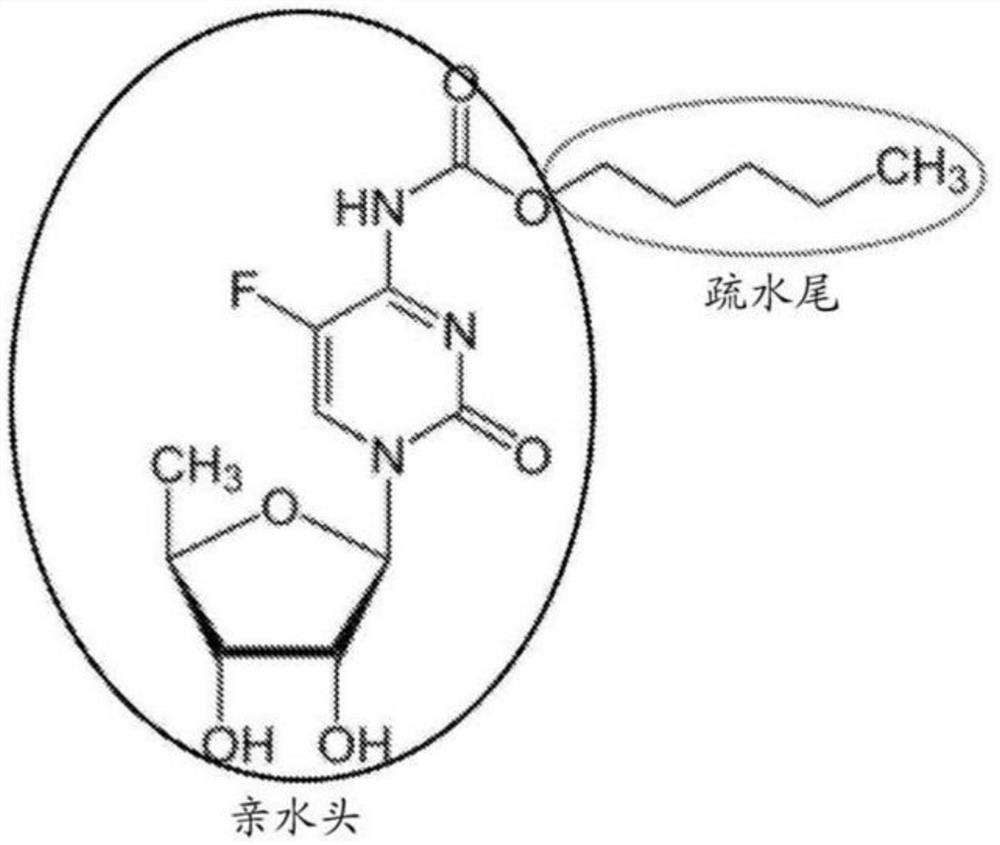

[0136] Capecitabine and phospholipid form micelles (see figure 1 ). The micelles are encapsulated by electrostatic interactions using oppositely charged polymers. Multiple layers of alternating charge polymers can be deposited on the particles if desired. Finally, the outermost layer of polyethylene glycol (PEG) provides steric stability and longer blood circulation time.

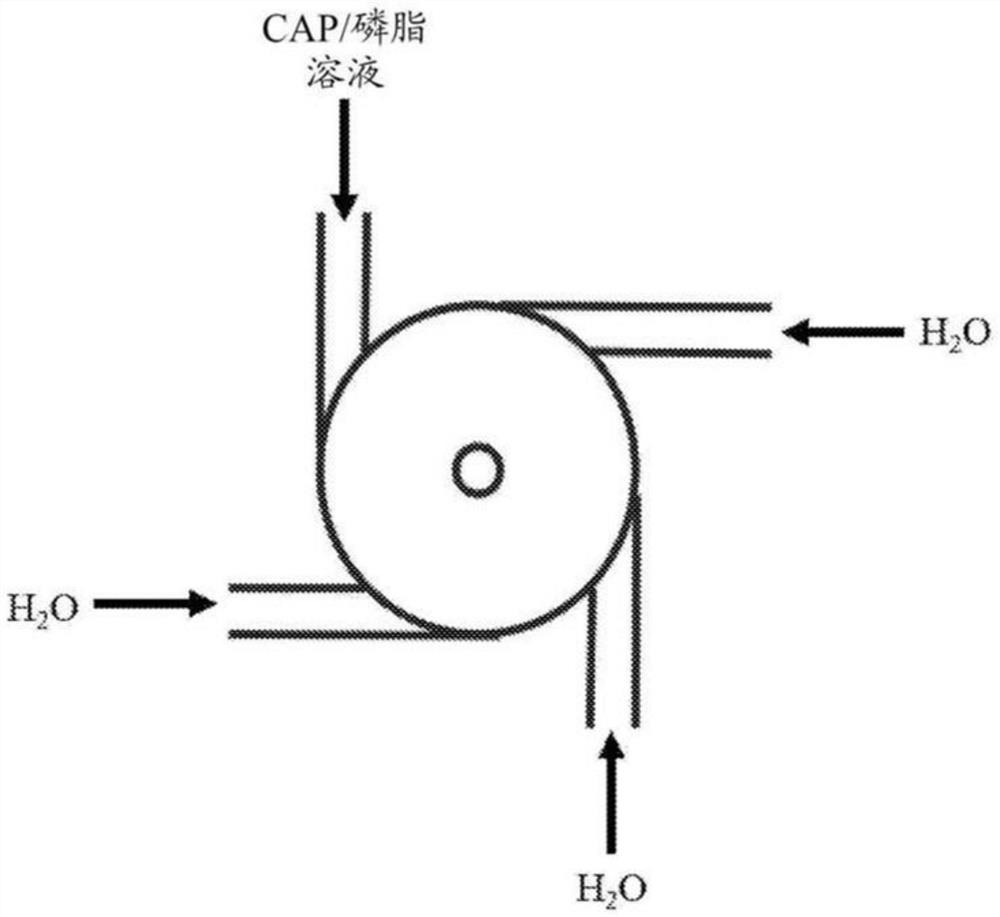

[0137] particle formation process

[0138] First, lipid-capecitabine micelles were generated by a rapid solvent exchange method using a multi-inlet vortex mixer (MIVM), followed by spray-drying or freeze-drying with leucine and trehalose. Specifically, MIVM is set as figure 2shown. The micellar suspension was lyophilized for 48 hours. Resuspend the dried powder in aqueous solution by vigorous mixing or sonication. The oppositely charged polymers were added to the lipid-CAP micelles. If mu...

Embodiment 2

[0144] Example 2: Formation of lipid-CAP micelles with neutral surfaces.

[0145] Two treatments have been used to generate micelles-film hydration and continuous mixing. To 215.6 μL of CAP (5 mg / ml), add 117.4 μL of DPPC (1,2-dipalmitoyl-sn-glycerol-3-phosphorylcholine) (25 mg / ml) and 329.9 μL of DPPE-PEG (1,2-distearoyl-sn-glycero-3-phosphoethanolamine-N-[methoxy(polyethylene glycol)-2000] (25 mg / ml). Mix the mixture well and evaporated under a stream of argon and placed under vacuum for at least 2 h. Then, the mixture was rehydrated with water and sonicated for 10 min. CAP, DPPC, and PEGylated lipid DPPE-PEG were dissolved in ethanol by continuous mixing , and rapidly mixed with DI water in MIVM in different volumes depending on the molar ratio. Fill the solution into a 5 mL gas-tight syringe and rapidly mix with the other three streams that are DI water. Mix the CAP / phospholipid solution stream and one of the water streams Pump at 6ml / min. Pump the other two streams at 5...

Embodiment 3

[0153] Example 3: Formation of lipid-CAP micelles with positively charged surfaces.

[0154] Two treatments have been used to create micelles – film rehydration and continuous mixing. By film hydration, both DOTAP (1,2-dioleoyl-3-trimethylammonium-propane) and CAP were dissolved in chloroform at a concentration of 10 mM. Equal volumes of DOTAP and CAP (500ul) solutions were mixed together and the mixture was evaporated under argon flow and then placed under vacuum for at least 2 hours to ensure complete solvent evaporation. The dried film was then rehydrated with 1 ml of DI water and sonicated for 10 min. Cationic phospholipids such as DOTAP are used to prepare micelles with CAP by continuous mixing. CAP (2mM) and DOTAP (2mM) were dissolved in ethanol. The solution was filled into a 5 mL gas-tight syringe and mixed rapidly in the MIVM with the other three streams being DI water. One of the streams of the CAP / phospholipid solution and the water stream was pumped at a rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com