An AC motor used in a range hood

A technology for AC motors and range hoods, applied in the direction of oil fume removal, electromechanical devices, applications, etc., can solve problems such as increased energy consumption, difficult temperature control, reduced motor life, etc., to improve sealing, prevent overheating, and guarantee The effect of safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

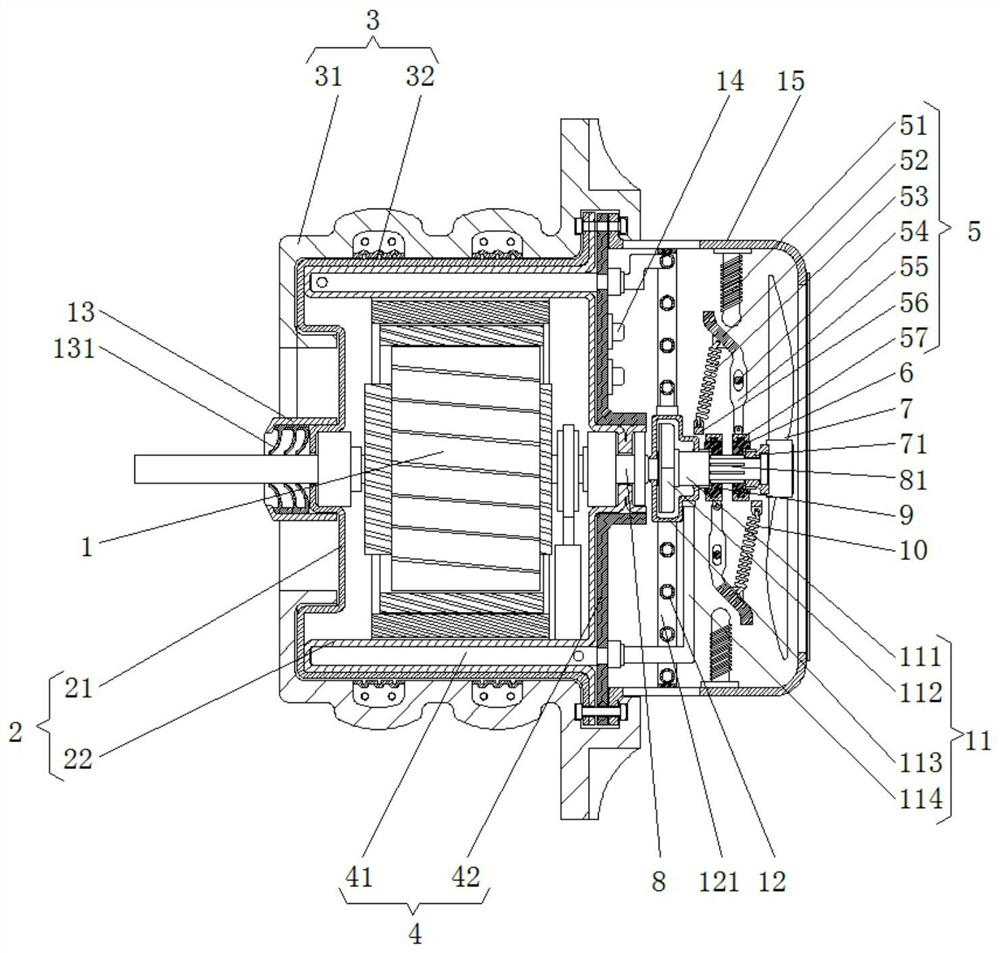

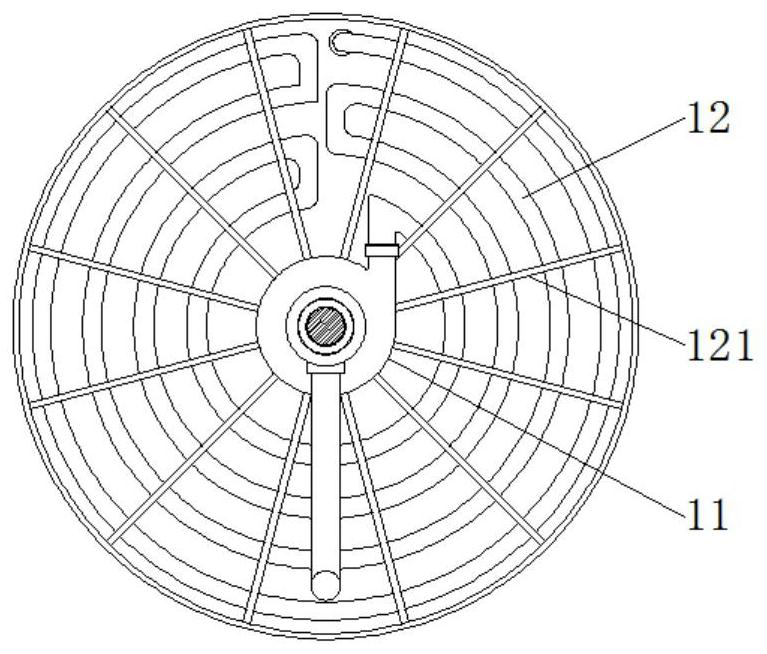

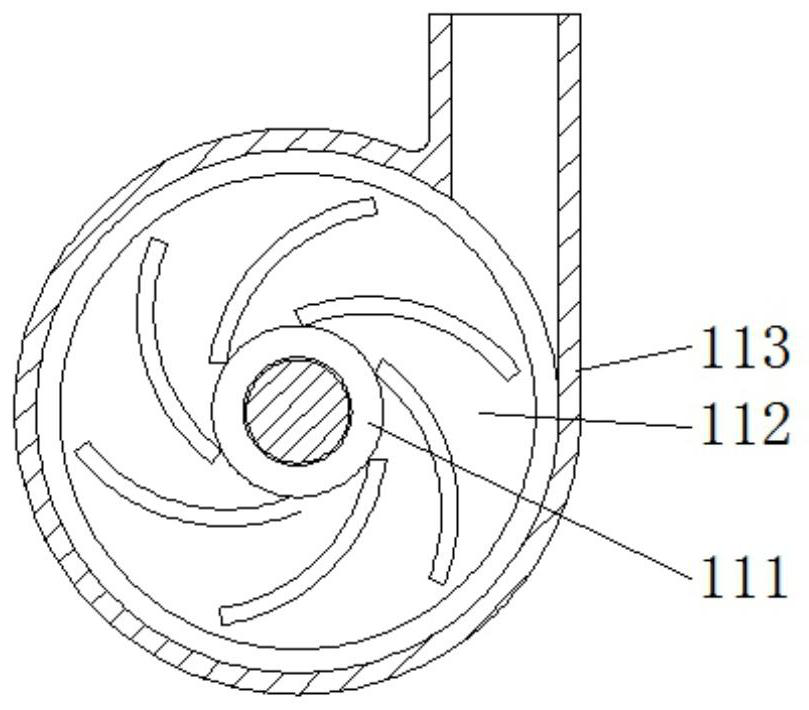

[0052] like Figure 1-Figure 15 As shown, an AC motor used in a range hood includes a casing 2, and a core 1 is arranged in the casing 2. The core 1 is composed of a stator core, a stator winding, a rotor core and a rotor winding. A central shaft 8 is arranged in the middle of 1. The casing 2 includes a front end casing 21 and a rear end casing 22 that are sleeved and connected to each other. The front end casing 21 and the rear end casing 22 are closely connected, and the The side wall is bent and folded outward to form an annular groove, and the inner cavity of the annular groove forms a circular channel through the guide spacer 4, and the two ends of the circular channel are cyclically communicated through the circulating pump 11 and the cooling coil 12; the central axis The rear end of 8 is provided with a synchronizing section 81. Outside the synchronizing section 81, the fan synchronizing ring 6 and the pump body synchronizing ring 9 are slidably connected to respectivel...

Embodiment 2

[0067] like Figure 1-Figure 15 As shown, an AC motor used in a range hood includes a casing 2, and a core 1 is arranged in the casing 2. The core 1 is composed of a stator core, a stator winding, a rotor core and a rotor winding. A central shaft 8 is arranged in the middle of 1. The casing 2 includes a front end casing 21 and a rear end casing 22 that are sleeved and connected to each other. The front end casing 21 and the rear end casing 22 are closely connected, and the The side wall is bent and folded outward to form an annular groove, and the inner cavity of the annular groove forms a circular channel through the guide spacer 4, and the two ends of the circular channel are cyclically communicated through the circulating pump 11 and the cooling coil 12; the central axis The rear end of 8 is provided with a synchronizing section 81. Outside the synchronizing section 81, the fan synchronizing ring 6 and the pump body synchronizing ring 9 are slidably connected to respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com