A method and application of immobilizing tyrosinase with polyacrylonitrile microspheres as carrier

A polyacrylonitrile microsphere, tyrosinase technology, applied in chemical instruments and methods, immobilized on/in organic carriers, oxidoreductase and other directions, can solve the immobilized enzyme activity temperature, pH tolerance Different problems, such as good reusability, good thermal stability and strong pH tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

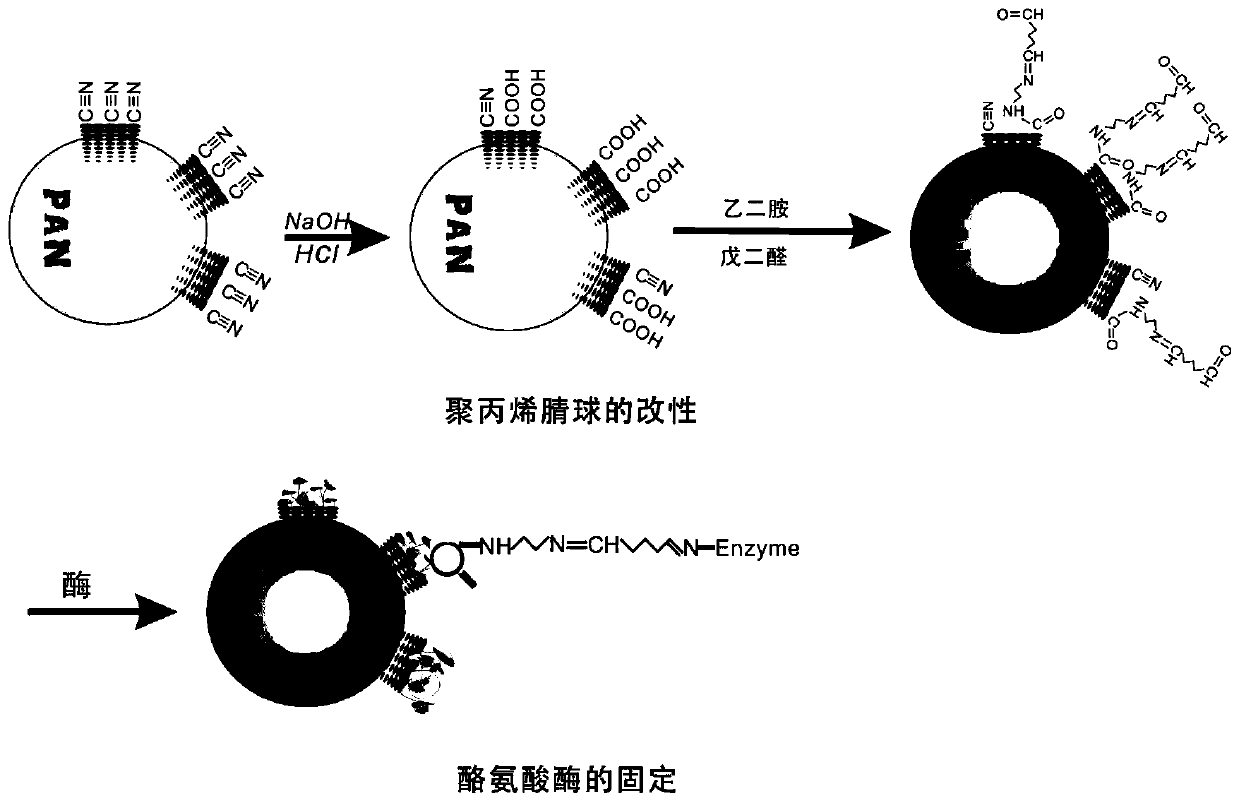

[0037] The method for immobilizing tyrosinase with polyacrylonitrile microspheres as a carrier comprises the following steps:

[0038] 1) 2g polyacrylonitrile is dissolved in 8g N-N dimethylformamide to form a homogeneous solution, and a phase inversion method is utilized to prepare polyacrylonitrile microspheres using a peristaltic pump;

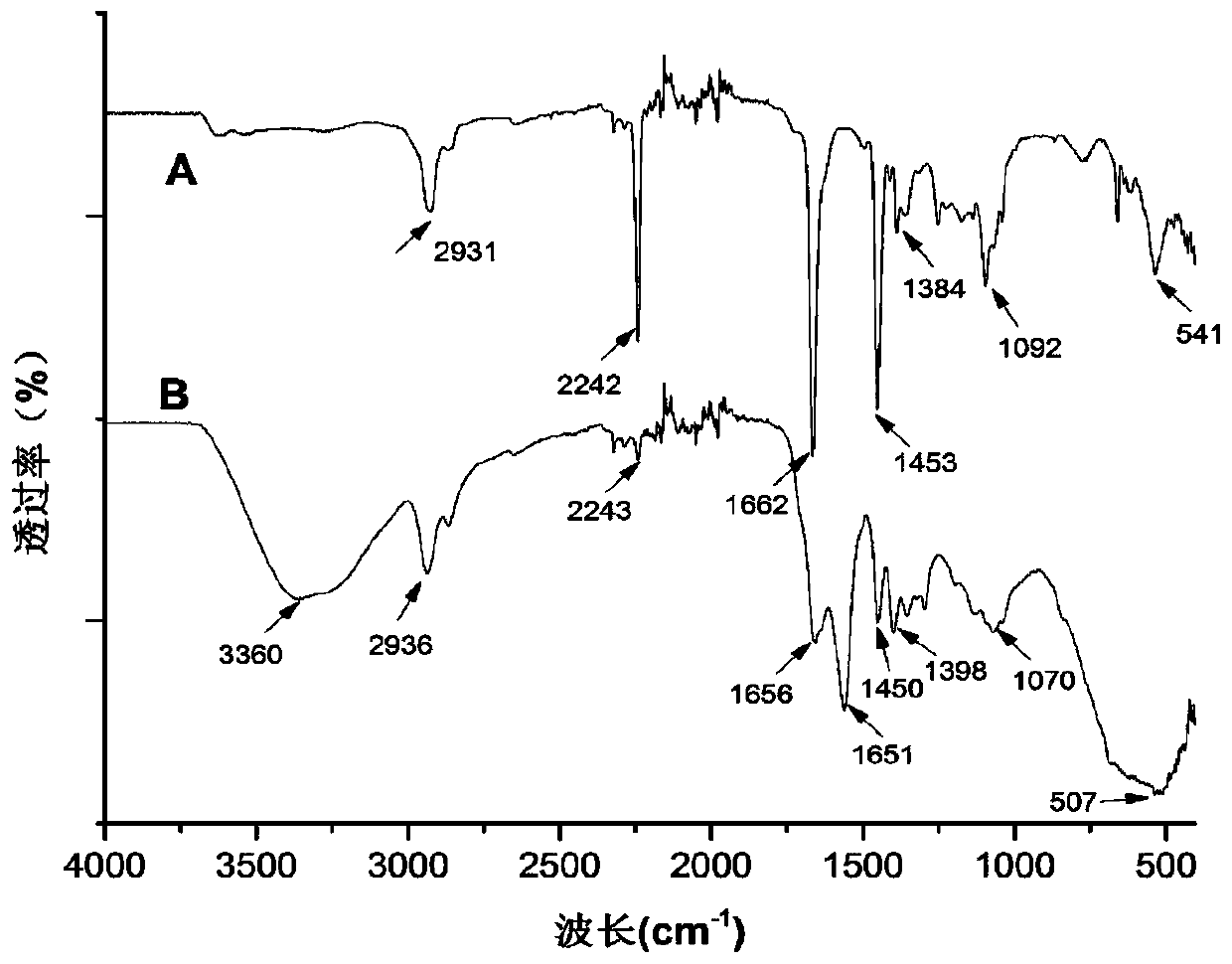

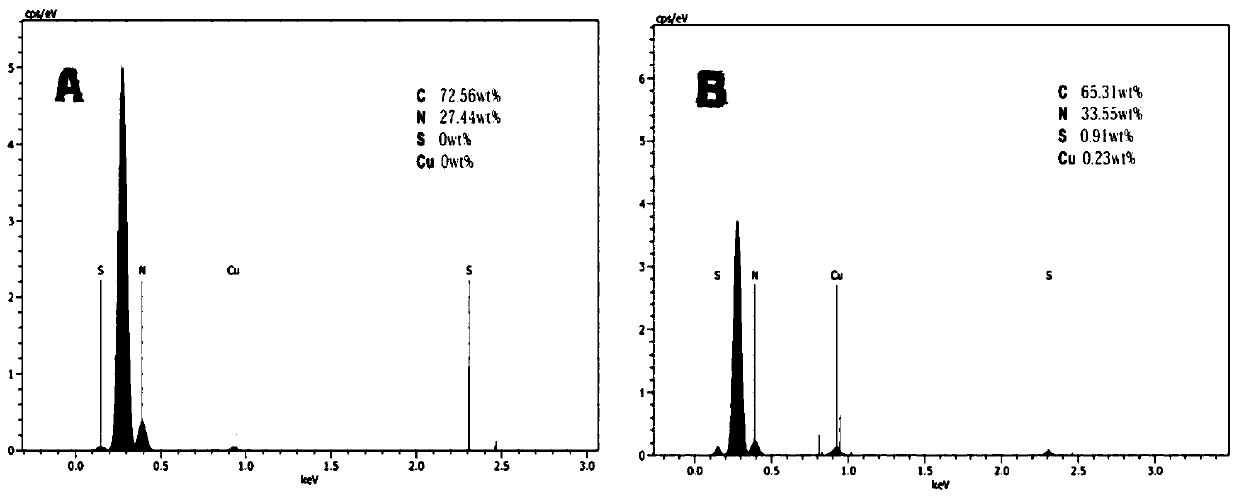

[0039] 2) Soak the polyacrylonitrile microspheres in 10wt% sodium hydroxide solution for 1 hour at 50°C, then take out the polyacrylonitrile microspheres and wash them with distilled water, then soak the carboxylated polyacrylonitrile microspheres in 0.1M hydrochloric acid for 2 hours at room temperature. Acrylonitrile microspheres, then soak the partially carboxylated polyacrylonitrile microspheres in 10wt% ethylenediamine solution for 1h to make them amidated (reaction temperature is 25°C), to obtain modified polyacrylonitrile microspheres;

[0040] 3) Contacting the modified polyacrylonitrile microspheres with 10 wt% glutaraldehyde solut...

Embodiment 2

[0044] The method for immobilizing tyrosinase with polyacrylonitrile microspheres as a carrier comprises the following steps:

[0045] 1) dissolving polyacrylonitrile in N-N dimethylformamide to form a homogeneous solution, and using a phase inversion method to prepare polyacrylonitrile microspheres using a peristaltic pump;

[0046]2) At 45°C, soak the polyacrylonitrile microspheres in 8wt% sodium hydroxide solution for 1.5h, then take out the polyacrylonitrile microspheres and wash them with distilled water, then soak them in 0.1M hydrochloric acid at room temperature for 2.5h Then the polyacrylonitrile microspheres of partial carboxylation were immersed in 8% ethylenediamine solution for 1.5h to make it amidate (the reaction temperature was 20°C), and the modified polyacrylonitrile was obtained. Microspheres;

[0047] 3) Contacting the modified polyacrylonitrile microspheres with 8 wt% glutaraldehyde solution at 4° C. for 1 h in the dark;

[0048] 4) Finally, contact the ...

Embodiment 3

[0051] The method for immobilizing tyrosinase with polyacrylonitrile microspheres as a carrier comprises the following steps:

[0052] 1) dissolving polyacrylonitrile in N-N dimethylformamide to form a homogeneous solution, and using a phase inversion method to prepare polyacrylonitrile microspheres using a peristaltic pump;

[0053] 2) At 50°C, soak the polyacrylonitrile microspheres in 10wt% sodium hydroxide solution for 1.2h, then take out the polyacrylonitrile microspheres and wash them with distilled water, then soak them in 0.1M hydrochloric acid at room temperature for 2.2h Polyacrylonitrile microspheres, then soak the partially carboxylated polyacrylonitrile microspheres in 8wt% ethylenediamine solution for 1.2h to make them amidate (reaction temperature is 40°C), to obtain modified polyacrylonitrile Microspheres;

[0054] 3) Contacting the modified polyacrylonitrile microspheres with 10 wt% glutaraldehyde solution at 4° C. for 1 h in the dark;

[0055] 4) Finally, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com